When it comes to printed circuit boards (PCBs), the standard thickness of 1.6mm is often the go-to choice for many designs. However, not all projects fit this mold. Specialized applications in industries like aerospace, automotive, and high-power electronics often demand non-standard PCB thickness—whether thicker for durability and heat dissipation or thinner for flexibility and compact designs. In this comprehensive guide, we’ll dive into the world of non-standard PCB thickness, exploring thick PCB applications, thin PCB applications, core materials, design constraints, and manufacturing limitations. Whether you're working on a high-power system or a flexible wearable device, understanding these options can elevate your design.

Why Non-Standard PCB Thickness Matters

PCB thickness directly impacts a board’s performance, reliability, and suitability for specific applications. While 1.6mm is a common standard due to its balance of strength and flexibility, many modern designs require something different. Non-standard PCB thickness options range from ultra-thin boards as low as 0.2mm to thick boards exceeding 3.2mm or even 6mm. These variations cater to unique needs, such as high-power handling, space constraints, or mechanical stability.

Choosing the right thickness isn't just about meeting physical requirements; it also affects electrical properties like impedance control and thermal management. For instance, a thicker board can handle higher current loads with better heat dissipation, while a thinner board might be crucial for fitting into a compact device. Let’s explore how these non-standard options apply to specialized fields and the factors that influence their use.

Thick PCB Applications: Power and Durability

Thick PCBs, typically ranging from 2.0mm to 6.0mm or more, are designed for applications where strength and high-power handling are critical. These boards often feature multiple layers and heavier copper weights to support demanding environments. Here are some key areas where thick PCB applications shine:

- High-Power Electronics: In industries like renewable energy and industrial automation, high-power PCB thickness is essential. Boards used in power inverters or motor controllers often need to handle currents exceeding 50A. A thicker board, combined with copper weights of 3oz or more per square foot, reduces resistance and prevents overheating. For example, a 3.2mm thick PCB can dissipate heat more effectively than a standard 1.6mm board, maintaining performance under heavy loads.

- Automotive Systems: Automotive electronics, such as those in electric vehicles (EVs), require robust boards to withstand vibration and temperature extremes. A thicker PCB, often around 2.4mm to 3.0mm, provides the mechanical stability needed for these harsh conditions while supporting power-intensive components.

- Military and Aerospace: Durability is non-negotiable in military and aerospace applications. Thick PCBs offer resistance to mechanical stress and can incorporate additional layers for complex circuitry, ensuring reliability in mission-critical systems.

Thin PCB Applications: Flexibility and Compact Design

On the other end of the spectrum, thin PCBs—ranging from 0.2mm to 1.0mm—are ideal for applications where space and weight are limited. These boards are often used in portable and wearable technology. Here’s where thin PCB applications make a difference:

- Wearable Devices: Devices like smartwatches and fitness trackers rely on ultra-thin PCBs to fit into small, lightweight designs. A board thickness of 0.4mm or less allows for compact layouts while maintaining functionality. Flexible PCB thickness often falls into this category, enabling the board to bend and conform to curved surfaces.

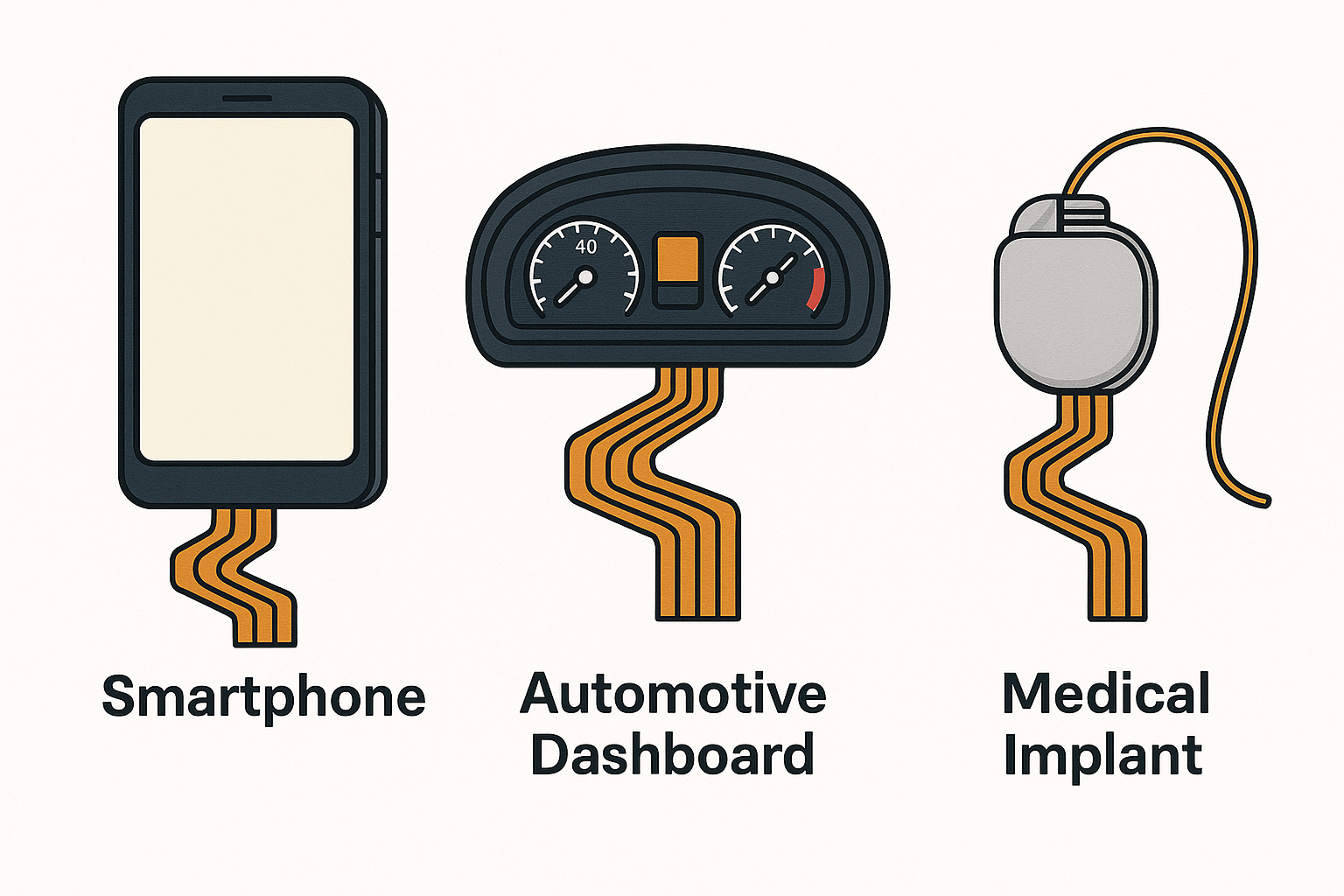

- Medical Equipment: Miniaturized medical devices, such as implantable sensors, benefit from thin PCBs. These boards must be lightweight and small, often requiring thicknesses below 0.6mm to fit within tight spaces without compromising performance.

- Consumer Electronics: Smartphones and tablets use thin PCBs to pack more components into slim profiles. Advanced designs may even incorporate substrate-like technology for higher component density, with board thicknesses as low as 0.3mm.

PCB Core Materials and Their Impact on Thickness

The choice of PCB core materials plays a significant role in determining the board’s thickness and performance. Different materials offer unique properties that suit specific applications, especially when working with non-standard PCB thickness. Let’s break down some common materials:

- FR-4: The most widely used material for standard and non-standard PCBs, FR-4 is a fiberglass-epoxy laminate known for its balance of cost and performance. It’s suitable for thicknesses ranging from 0.4mm to over 3.2mm, making it versatile for both thick and thin designs. However, for high-frequency or high-power applications, FR-4 may not offer the best thermal conductivity or signal integrity.

- Polyimide: Often used in flexible PCBs, polyimide is ideal for ultra-thin designs (0.2mm to 0.5mm). It offers excellent thermal stability and flexibility, making it a top choice for wearable and medical applications where thin PCB applications are common.

- High-Tg Materials: For high-power PCB thickness designs, high glass transition temperature (Tg) materials are used to withstand elevated temperatures. These materials are often paired with thicker boards (2.0mm and above) to enhance heat dissipation in power electronics.

- Metal-Core (MCPCB): Metal-core PCBs, often using aluminum or copper as the base, are designed for superior thermal management in thick PCB applications. These boards can range from 1.6mm to 3.2mm or more and are commonly used in LED lighting and power supply systems.

Selecting the right core material ensures that the PCB thickness aligns with the application’s electrical, thermal, and mechanical needs. For instance, a 2.4mm thick board with a metal core can handle thermal loads better than a standard FR-4 board of the same thickness, extending the lifespan of high-power components.

PCB Design Constraints with Non-Standard Thickness

While non-standard PCB thickness opens up new possibilities, it also introduces design constraints that engineers must navigate. Understanding these limitations is crucial for creating a successful board. Here are some key challenges:

- Impedance Control: PCB thickness affects trace impedance, especially in high-frequency designs. For example, a thinner board (0.5mm) may require narrower traces to achieve a 50-ohm impedance, which can complicate manufacturing. Conversely, thicker boards (3.2mm) may need wider traces, increasing the board’s footprint.

- Component Compatibility: Non-standard thicknesses can impact component placement. Ultra-thin PCBs may not support heavy components due to reduced mechanical strength, while very thick boards might create clearance issues in tight enclosures.

- Layer Stackup: Achieving the desired thickness often involves adjusting the number of layers or dielectric spacing. For instance, a 4.0mm thick PCB might require additional prepreg layers, which can increase costs and affect signal integrity if not designed properly.

- Thermal Management: While thicker boards generally dissipate heat better, they can also retain more heat in densely packed designs. Thin boards, on the other hand, may struggle with thermal dissipation, requiring additional cooling solutions.

Balancing these constraints requires careful planning during the design phase. Using simulation tools to model impedance and thermal behavior can help optimize a non-standard PCB for its intended application.

PCB Manufacturing Limitations for Non-Standard Thickness

Manufacturing non-standard PCB thickness comes with its own set of challenges. Not all fabrication processes are equipped to handle extreme thicknesses, and these limitations can affect cost, lead time, and quality. Here’s what to consider:

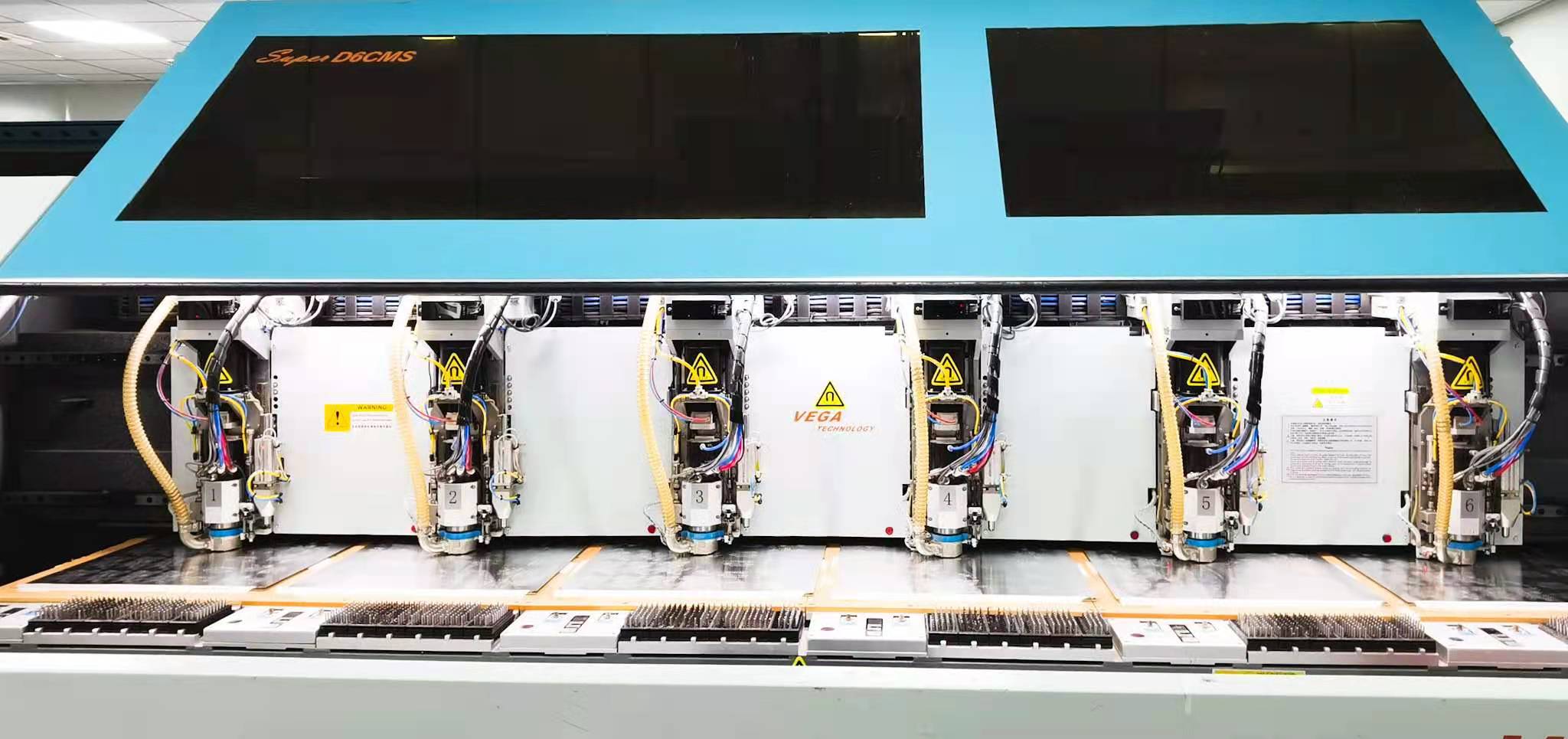

- Tooling and Equipment: Standard PCB manufacturing equipment is optimized for thicknesses around 1.6mm. Producing ultra-thin (below 0.4mm) or very thick (above 3.2mm) boards often requires specialized tools, which can increase production costs.

- Material Handling: Thin PCBs are more prone to warping or breaking during manufacturing, especially flexible PCB thickness designs below 0.3mm. Thick boards, meanwhile, may face issues with uniform lamination and drilling accuracy due to their increased rigidity.

- Cost Implications: Non-standard thicknesses typically lead to higher costs due to custom material sourcing and adjusted manufacturing processes. For example, a 0.2mm flexible PCB might cost 20-30% more per unit than a standard board due to the precision required.

- Lead Times: Specialized production runs for non-standard thicknesses can extend lead times. Manufacturers may need to source unique materials or adjust production schedules, delaying delivery by days or weeks.

To mitigate these limitations, partnering with a manufacturer experienced in non-standard designs is essential. Clear communication about design specifications and application requirements can streamline the production process and ensure quality.

High-Power PCB Thickness: Meeting Extreme Demands

High-power PCB thickness is a critical factor in applications where electrical and thermal performance are pushed to the limit. Boards in this category often exceed 2.0mm and incorporate heavy copper layers (up to 6oz or more) to handle high currents. For instance, a power supply unit operating at 100A might use a 3.2mm thick PCB with 4oz copper to minimize voltage drops and heat buildup.

In addition to thickness, thermal vias and metal-core materials are often used to enhance heat dissipation. A well-designed high-power PCB can maintain stable operation at temperatures above 100°C, protecting components from failure. Industries like renewable energy, where solar inverters convert high DC currents to AC, rely heavily on these robust designs to ensure long-term reliability.

Flexible PCB Thickness: Adapting to Dynamic Needs

Flexible PCB thickness, typically ranging from 0.1mm to 0.5mm, is a game-changer for applications requiring adaptability. These boards are made from materials like polyimide, allowing them to bend and fold without breaking. Common uses include:

- Dynamic Flexing: In devices with moving parts, such as robotic arms or foldable smartphones, flexible PCBs withstand repeated bending without losing conductivity.

- Space-Saving Designs: Flexible PCBs eliminate the need for bulky connectors by folding into tight spaces, ideal for compact electronics.

However, designing with flexible PCB thickness requires careful attention to bend radius and material fatigue. A board that’s too thin (e.g., 0.1mm) might tear under stress, while one that’s too thick (e.g., 0.5mm) may lose flexibility. Balancing these factors ensures the board meets both mechanical and electrical requirements.

Choosing the Right Thickness for Your Application

Selecting the appropriate PCB thickness for a specialized application involves weighing several factors: electrical performance, mechanical strength, thermal needs, and manufacturing feasibility. Here are some practical tips to guide your decision:

- Define Application Requirements: Determine the primary needs of your project. Does it require high current handling (thicker board) or compactness (thinner board)?

- Consider Environmental Factors: Will the PCB operate in harsh conditions like high vibration or extreme heat? Thicker boards often provide better durability.

- Evaluate Cost vs. Performance: Non-standard thicknesses can increase costs, so ensure the benefits justify the expense. For instance, a 0.3mm flexible PCB might be pricier but necessary for a wearable device.

- Consult with Manufacturers Early: Engage with your PCB fabricator during the design phase to confirm that your chosen thickness is manufacturable within your timeline and budget.

Conclusion: Unlocking Innovation with Non-Standard PCB Thickness

Stepping beyond the standard 1.6mm PCB thickness opens up a world of possibilities for specialized applications. Whether you’re designing for high-power systems with thick PCBs or compact wearables with thin, flexible boards, understanding non-standard PCB thickness options is key to innovation. By considering core materials, design constraints, and manufacturing limitations, you can create boards that meet the unique demands of your project.

From high-power PCB thickness for industrial applications to flexible PCB thickness for dynamic designs, the right choice can enhance performance, reliability, and efficiency. As technology continues to evolve, exploring these non-standard options will remain a vital part of pushing boundaries in electronics design. With careful planning and collaboration with experienced manufacturers, you can bring even the most challenging concepts to life.

ALLPCB

ALLPCB