When it comes to PCB depanelization methods, the choice between mouse bites and V-scoring often depends on your project’s specific needs, budget, and design constraints. Both techniques are widely used in PCB separation techniques to break individual boards from a larger panel after manufacturing. Mouse bites offer a cost-effective and flexible solution with easy manual separation, while V-scoring provides cleaner edges and is ideal for high-volume production with automated processes. In this comprehensive guide, we’ll dive into the advantages of each method, compare costs, and help you decide which approach suits your project best.

Whether you’re an engineer working on a prototype or managing large-scale production, understanding these PCB separation techniques is crucial for optimizing efficiency and ensuring quality. Let’s explore the intricacies of mouse bites and V-scoring to uncover their benefits, limitations, and practical applications in PCB depanelization.

What Is PCB Depanelization and Why Does It Matter?

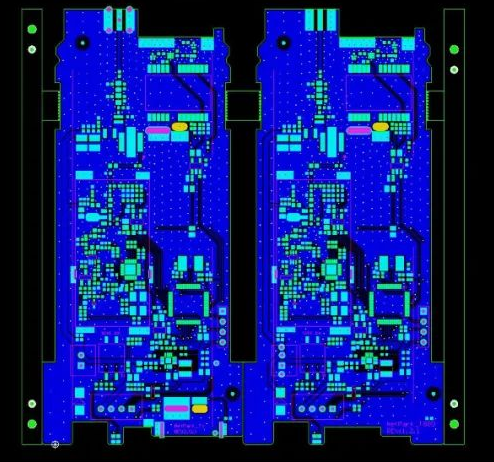

PCB depanelization is the process of separating individual printed circuit boards (PCBs) from a larger panel after manufacturing. During production, multiple PCBs are often fabricated together on a single panel to save time and reduce costs. Once the assembly and testing are complete, these boards must be separated without damaging components or compromising structural integrity.

Choosing the right depanelization method is essential because it affects the board’s edge quality, the risk of damage to components, production speed, and overall cost. Poor separation techniques can lead to micro-cracks, stress on solder joints, or uneven edges that impact the board’s performance. Common methods include mouse bites, V-scoring, routing, and laser cutting, but mouse bites and V-scoring remain the most popular due to their balance of cost and effectiveness.

In this blog, we’ll focus on mouse bites and V-scoring, diving into their advantages, drawbacks, and cost comparisons to help you make an informed decision for your next project.

Understanding Mouse Bites in PCB Depanelization

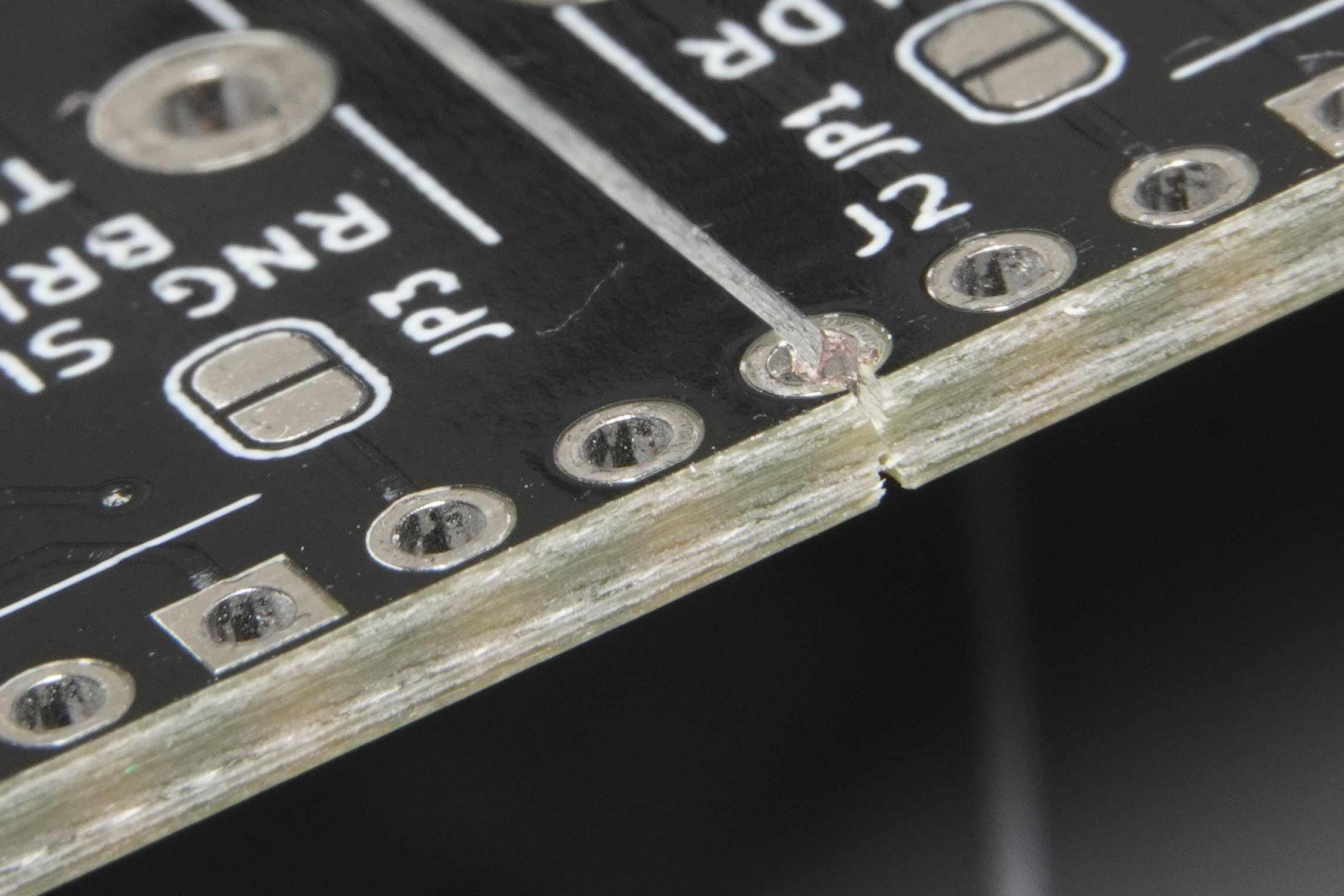

Mouse bites are small, perforated breakaway tabs used to connect individual PCBs within a panel. These tabs consist of a series of small holes drilled along the separation line, creating a weak point that allows the boards to be snapped apart manually or with minimal force. The name "mouse bites" comes from the appearance of these perforations, resembling tiny bite marks.

Mouse Bites Advantages

Mouse bites are a popular choice in PCB depanelization methods for several reasons:

- Cost-Effective: Mouse bites require minimal tooling and setup, making them an economical option for low to medium-volume production runs. The process of drilling small holes is simple and doesn’t demand specialized equipment beyond standard PCB fabrication tools.

- Flexibility in Design: They can be used on almost any board shape or size, including irregular or complex geometries where other methods like V-scoring might not be feasible.

- Easy Separation: Boards connected by mouse bites can often be separated by hand without additional tools, which is ideal for prototypes or small batches where automation isn’t necessary.

- Minimal Stress on Components: When designed correctly, mouse bites reduce the stress on nearby components during separation compared to methods that require significant force or cutting.

Mouse bites are often used in prototype development or small-scale projects where budget constraints are a priority. For instance, in a project requiring only 50 boards, the cost savings from using mouse bites can be significant compared to investing in automated depanelization equipment.

Drawbacks of Mouse Bites

Despite their advantages, mouse bites have some limitations:

- Rough Edges: After separation, the edges where mouse bites were located can be uneven or jagged, which may not be suitable for applications requiring a polished finish.

- Manual Effort: While easy to separate, manual depanelization can be time-consuming for larger volumes and may lead to inconsistent results if not done carefully.

- Space Constraints: Mouse bites require a small amount of board space for the perforated tabs, which might not be ideal for densely packed designs where every millimeter counts.

Exploring V-Scoring as a PCB Separation Technique

V-scoring, also known as V-grooving, involves cutting a V-shaped groove along the separation line on both sides of the PCB panel. This groove weakens the material, allowing the boards to be snapped apart along the scored line. V-scoring is typically done with a specialized scoring machine during the manufacturing process.

V-Scoring Advantages

V-scoring offers distinct benefits that make it a preferred method in many production scenarios:

- Cleaner Edges: Compared to mouse bites, V-scoring results in smoother and more uniform edges after separation, which is critical for applications where aesthetics or precise fitting is important.

- Suitable for High-Volume Production: V-scoring is highly compatible with automated depanelization processes, making it efficient for large-scale manufacturing where speed and consistency are key.

- Space Efficiency: The V-groove takes up less space than mouse bite tabs, allowing for tighter panel layouts and maximizing the use of board real estate.

- Reduced Risk of Damage: When done with precision, V-scoring minimizes stress on components near the separation line, reducing the likelihood of micro-cracks or solder joint failures.

For example, in a high-volume production run of 10,000 units, V-scoring can save significant time by enabling automated separation, ensuring each board maintains consistent quality with minimal post-processing.

Drawbacks of V-Scoring

While V-scoring is effective, it comes with some challenges:

- Higher Initial Cost: The setup for V-scoring requires specialized equipment and precise alignment, which can increase upfront costs, especially for small runs or prototypes.

- Limited to Straight Lines: V-scoring is generally restricted to straight separation lines, making it less versatile for boards with irregular shapes or complex panel layouts.

- Material Thickness Constraints: V-scoring works best on thinner boards (typically under 3.2 mm). Thicker boards may not snap cleanly, leading to potential damage.

Cost Comparison: Mouse Bites vs. V-Scoring

One of the most critical factors in choosing between mouse bites and V-scoring is cost. Let’s break down the cost comparison of mouse bites vs. V-scoring to help you understand where each method shines.

Mouse Bites Cost Factors

Mouse bites are generally more affordable for small to medium production runs due to their simplicity. The process involves standard drilling techniques that are already part of most PCB fabrication workflows, so there’s little to no additional tooling cost. For a small batch of 100 boards, the cost of implementing mouse bites might only add a negligible amount per board, often less than $0.10 per unit, depending on the panel size and complexity.

However, for larger volumes, the manual separation process can increase labor costs. If each board takes just 10 seconds to separate by hand, a batch of 1,000 boards could require over 2.5 hours of labor, which adds up quickly at standard hourly rates.

V-Scoring Cost Factors

V-scoring tends to have a higher initial cost due to the need for specialized scoring equipment and setup. For small runs, this cost can be prohibitive, with setup fees potentially ranging from $50 to $200 depending on the manufacturer and panel complexity. However, for high-volume production, the per-unit cost drops significantly. In a run of 10,000 boards, the setup cost becomes negligible when spread across each unit, and automated separation reduces labor expenses.

In summary, mouse bites are often the go-to choice for prototypes and small batches due to their low cost and ease of use. V-scoring, on the other hand, becomes more cost-effective as production volume increases, especially when automation is factored in.

Practical Applications: When to Use Mouse Bites or V-Scoring

Deciding between mouse bites and V-scoring often comes down to the specific requirements of your project. Here are some scenarios to guide your decision:

- Prototypes and Small Batches: If you’re working on a prototype or a small run (under 500 units), mouse bites are usually the better choice. Their low cost and ease of manual separation make them ideal for quick iterations and testing.

- High-Volume Production: For large-scale manufacturing (1,000 units or more), V-scoring is often more efficient. The cleaner edges and compatibility with automated systems can save time and ensure consistent quality.

- Complex Board Shapes: If your PCB design involves irregular shapes or non-linear separation lines, mouse bites offer the flexibility that V-scoring lacks.

- Aesthetic or Fitting Requirements: When the final product requires smooth edges for aesthetic reasons or precise fitting into enclosures, V-scoring is the preferred method.

For instance, a startup developing a new IoT device might use mouse bites during the initial 50-unit prototype phase to keep costs low. Once the design is finalized and production scales to 5,000 units, switching to V-scoring could streamline the process and improve the product’s finish.

Design Considerations for Effective Depanelization

Regardless of whether you choose mouse bites or V-scoring, proper design is critical to ensure successful depanelization without damaging the boards. Here are some tips to keep in mind:

- Component Placement: Avoid placing components too close to the separation lines, as the stress from breaking the boards apart can damage solder joints or cause micro-cracks. A clearance of at least 5 mm is recommended for most designs.

- Panel Layout: Optimize the panel layout to minimize wasted space while ensuring there’s enough room for mouse bites or V-grooves. For V-scoring, ensure all separation lines are straight and aligned with the scoring machine’s capabilities.

- Material and Thickness: Consider the PCB material and thickness when selecting a depanelization method. For boards thicker than 3.2 mm, mouse bites or alternative methods like routing might be necessary, as V-scoring may not work effectively.

- Testing Separation: Before finalizing a large production run, test the depanelization process on a small batch to ensure the chosen method doesn’t cause unintended damage or stress.

Conclusion: Making the Right Choice for Your PCB Project

Both mouse bites and V-scoring are proven PCB depanelization methods, each with unique strengths that cater to different project needs. Mouse bites stand out for their cost-effectiveness and flexibility, making them a go-to option for prototypes and small runs. V-scoring, with its cleaner edges and suitability for automation, excels in high-volume production where efficiency and quality are paramount.

By considering factors like production volume, board design, edge finish requirements, and budget, you can choose the method that best aligns with your goals. Whether you’re optimizing for cost with mouse bites or prioritizing precision with V-scoring, understanding these PCB separation techniques ensures your project runs smoothly from fabrication to final assembly.

At ALLPCB, we’re committed to supporting your PCB manufacturing journey with expert guidance and high-quality services. Explore our resources and tools to streamline your next project, and make informed decisions that elevate your designs.

ALLPCB

ALLPCB