If you're an electrical engineer working on an electric vehicle (EV) battery management system (BMS), one of the most critical decisions you'll make is selecting the right BMS microcontroller. The microcontroller acts as the brain of your BMS, handling tasks like monitoring battery health, ensuring safety, and communicating with other vehicle systems. So, how do you choose the best one? Focus on key factors like processing power, functional safety MCU certifications, automotive grade microcontroller standards, ADC resolution, and supported communication interfaces CAN, SPI, LIN. In this blog, we'll dive deep into these aspects with ALLPCB to help you make an informed choice for your EV battery management PCB.

Why Choosing the Right BMS Microcontroller Matters

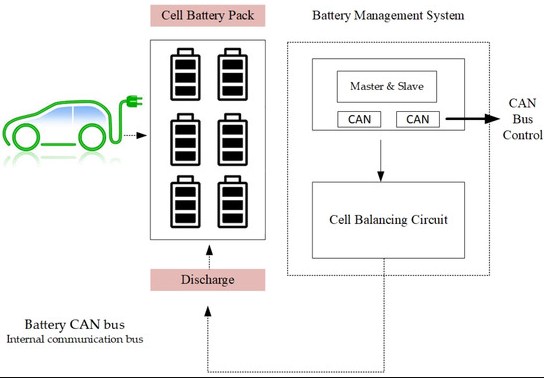

A battery management system is the heart of any electric vehicle, ensuring the battery pack operates safely and efficiently. The BMS microcontroller is responsible for critical tasks like measuring cell voltages, balancing cells, monitoring temperatures, and protecting against overcharge or over-discharge. A poor choice can lead to inaccurate data, safety risks, or system failures. On the other hand, selecting a microcontroller with the right specs—such as a high ADC resolution for precise measurements or robust communication interfaces CAN, SPI, LIN for integration—can optimize performance and extend battery life.

In this post, we'll break down the essential criteria for selecting a microcontroller tailored for EV BMS applications. Whether you're undergoing a advanced PCB design for a small electric scooter or a high-performance EV, these insights will guide you through the process.

Key Factors in Selecting a BMS Microcontroller

Let's explore the critical considerations for choosing the best microcontroller for your EV battery management PCB. We'll focus on technical specs and standards that matter most to electrical engineers.

1. Processing Power and Architecture: Why ARM Cortex-M is a Top Choice

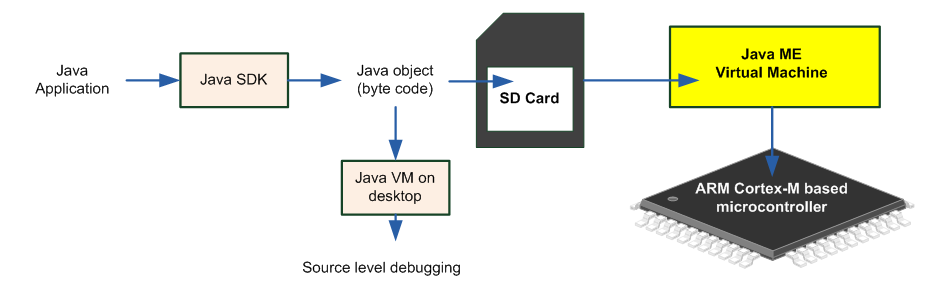

The processing power of your BMS microcontroller determines how quickly and efficiently it can handle complex algorithms for state-of-charge (SoC) estimation, state-of-health (SoH) monitoring, and real-time decision-making. For most EV BMS applications, microcontrollers based on the ARM Cortex-M architecture are a popular choice due to their balance of performance, power efficiency, and scalability.

For instance, the ARM Cortex-M4 or Cortex-M7 cores offer 32-bit processing with clock speeds ranging from 48 MHz to over 200 MHz, providing ample power for BMS tasks. They also support floating-point units (FPUs), which are crucial for precise calculations in battery algorithms. A practical example is the STM32F4 series from STMicroelectronics, widely used in automotive applications, offering up to 180 MHz clock speed and integrated peripherals tailored for BMS needs.

2. Functional Safety MCU: Meeting Automotive Standards

Safety is non-negotiable in EV applications. A functional safety MCU compliant with ISO 26262 standards (up to ASIL-D level) is essential for ensuring your BMS can handle critical failures without risking the vehicle or its occupants. This standard defines Automotive Safety Integrity Levels (ASIL), with ASIL-D being the highest level of safety requirement.

For example, NXP's MPC5775B and MPC5775E microcontrollers are designed specifically for BMS and inverter applications, offering ASIL-D compliance. They include features like error correction codes (ECC) on memory, redundant processing units, and built-in self-test (BIST) mechanisms to detect hardware faults. Choosing a functional safety MCU not only meets regulatory demands but also builds trust in your system's reliability.

3. Automotive Grade Microcontroller: Durability for Harsh Conditions

An EV operates in extreme conditions—think temperature ranges from -40°C to 85°C, high vibration, and electromagnetic interference (EMI). That's why selecting an automotive grade microcontroller is critical. These MCUs are tested to meet AEC-Q100 standards, ensuring they can withstand thermal stress, mechanical shock, and electrical noise.

Take Texas Instruments' TMS570 series as an example. These automotive-grade MCUs are built for harsh environments, offering robust performance with dual-core lockstep architecture for safety and extended temperature ranges. When designing your EV battery management PCB, always check the MCU's datasheet for AEC-Q100 qualification to ensure long-term reliability.

4. ADC Resolution: Precision in Battery Monitoring

Accurate measurement of battery parameters like voltage, current, and temperature is vital for a BMS. This is where ADC resolution comes into play. The Analog-to-Digital Converter (ADC) in your microcontroller converts analog signals from sensors into digital data for processing. A higher ADC resolution—measured in bits—means more precise measurements.

For EV BMS applications, a minimum of 12-bit ADC resolution is recommended, though 16-bit or higher is ideal for high-precision tasks. For instance, a 12-bit ADC can distinguish between 4096 voltage levels, while a 16-bit ADC can resolve 65,536 levels, offering finer granularity. This is critical when monitoring cell voltages in a battery pack, where differences as small as 10 mV can indicate imbalance or degradation. Microcontrollers like the Infineon AURIX TC3xx series provide 12-bit to 16-bit ADCs with fast conversion times (under 1 μs), ensuring accurate real-time monitoring.

Tip: When selecting a microcontroller, also consider the ADC's sampling rate and input channel count to match the number of cells and sensors in your battery pack.

5. Communication Interfaces: CAN, SPI, and LIN for Seamless Integration

A BMS doesn't operate in isolation—it needs to communicate with other vehicle systems like the motor controller, charger, and central ECU. This requires robust communication interfaces CAN, SPI, LIN on your microcontroller.

- CAN (Controller Area Network): The de facto standard for automotive communication, CAN supports high-speed, reliable data transfer (up to 1 Mbps) over long distances. It's used for real-time BMS data exchange with other ECUs. Most automotive MCUs, like the Microchip PIC32CM series, include multiple CAN interfaces with CAN-FD support for faster data rates.

- SPI (Serial Peripheral Interface): SPI is ideal for high-speed, short-distance communication between the microcontroller and peripherals like ADCs or memory chips on the PCB. It can achieve speeds up to 50 MHz, making it perfect for fast data acquisition in a BMS.

- LIN (Local Interconnect Network): LIN is a low-cost, low-speed (up to 20 kbps) protocol used for non-critical communications, such as connecting to simple sensors or actuators. It's less common in high-end BMS designs but useful for cost-sensitive applications.

Ensure your microcontroller supports multiple instances of these interfaces to handle simultaneous communications. For example, the Renesas RH850 series offers integrated CAN, SPI, and LIN modules, making it a versatile choice for BMS designs.

6. Power Efficiency: Extending Battery Life

Since a BMS is always active to monitor the battery, power efficiency is a key concern. Look for microcontrollers with low-power modes (like sleep or deep-sleep modes) to minimize energy consumption during idle periods. For instance, the STM32L4 series from STMicroelectronics consumes as little as 30 nA in shutdown mode, which is crucial for preserving battery life in EVs when the vehicle is parked for long periods.

Additionally, check the MCU's operating voltage range. Many modern BMS designs use 3.3V or lower to reduce power draw, so ensure compatibility with your PCB's power supply design.

7. Peripheral Integration: Simplifying PCB Design

A microcontroller with integrated peripherals can reduce the component count on your EV battery management PCB, saving space and cost. Look for features like:

- Built-in comparators for overvoltage/undervoltage protection.

- Integrated temperature sensors for monitoring MCU health.

- Hardware-based PWM (Pulse Width Modulation) for controlling balancing circuits.

For example, the Cypress PSoC 6 series offers programmable analog and digital blocks, allowing you to customize peripherals for specific BMS tasks without adding external components.

Comparing Popular Microcontrollers for EV BMS

To make your decision easier, here's a comparison of three popular microcontrollers often used in EV BMS designs. This table highlights their key specs relevant to BMS applications.

| Microcontroller | Core | ADC Resolution | Communication Interfaces | Functional Safety | Automotive Grade |

|---|---|---|---|---|---|

| STM32F4 (STMicroelectronics) | ARM Cortex-M4 | 12-bit | CAN, SPI, LIN | ASIL-B | AEC-Q100 |

| NXP MPC5775B | Power Architecture | 12-bit | CAN-FD, SPI, LIN | ASIL-D | AEC-Q100 |

| Infineon AURIX TC3xx | TriCore | 12-bit to 16-bit | CAN-FD, SPI, LIN | ASIL-D | AEC-Q100 |

This comparison shows that while all three are viable, your choice depends on specific needs. If functional safety MCU compliance at ASIL-D is critical, NXP or Infineon might be better. For higher ADC resolution, Infineon's AURIX stands out.

Practical Tips for BMS Microcontroller Selection

Here are some actionable tips to guide your selection process:

- Match Specs to Battery Pack Size: For a small pack with 4-8 cells, a simpler MCU like STM32F0 might suffice. For larger packs (48V or higher), opt for high-performance MCUs with more ADC channels and processing power.

- Prototype and Test: Before finalizing, prototype PCB with the chosen MCU and test under real-world conditions. Check for ADC accuracy, communication reliability, and thermal performance.

- Consider Development Tools: Choose an MCU with a strong ecosystem—good documentation, IDE support, and community forums can save hours of debugging. For instance, ARM Cortex-M-based MCUs benefit from widespread tool support like Keil uVision or STM32CubeIDE.

- Plan for Scalability: Select a microcontroller family with multiple variants so you can upgrade or downgrade based on future design needs without relearning a new platform.

Common Challenges and How to Overcome Them

Designing an EV BMS PCB comes with challenges. Here are two common issues related to microcontroller selection and solutions:

Challenge 1: Insufficient ADC Channels

If your battery pack has many cells (e.g., 16 or more), a single MCU might not have enough ADC inputs. Solution: Use an external ADC or multiplexer IC to expand input channels, or opt for a microcontroller with a higher channel count like the AURIX TC3xx (up to 60 ADC channels).

Challenge 2: Communication Bottlenecks

High-speed data transfer via CAN or SPI can face bottlenecks if the MCU can't keep up. Solution: Choose an MCU with hardware-accelerated communication modules and higher clock speeds to ensure smooth data flow.

Conclusion: Making the Right Choice for Your EV BMS

Selecting the right BMS microcontroller for your EV battery management PCB is a balance of technical requirements and practical constraints. Prioritize factors like ARM Cortex-M architecture for performance, functional safety MCU compliance for reliability, automotive grade microcontroller standards for durability, ADC resolution for precision, and robust communication interfaces CAN, SPI, LIN for integration. By carefully evaluating your battery pack's needs and testing your design, you can ensure optimal performance and safety for your EV system.

ALLPCB

ALLPCB