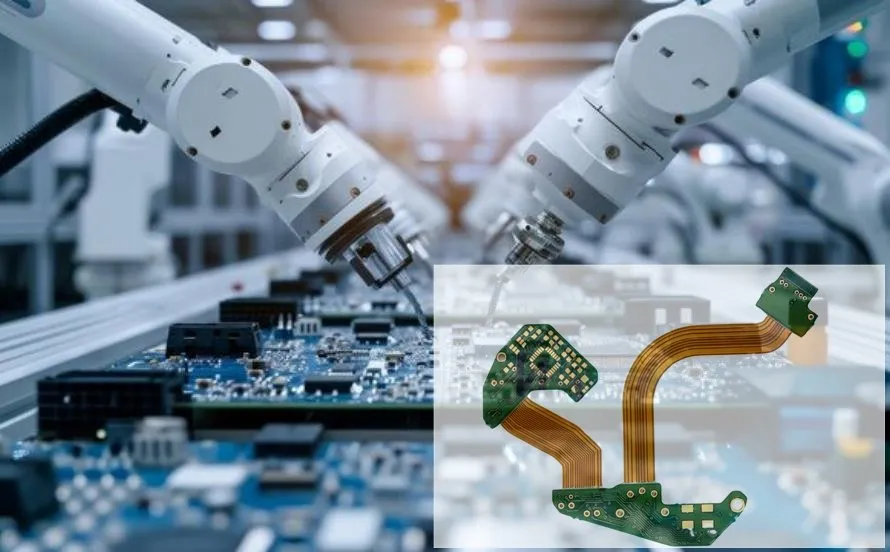

In the fast-evolving world of robotics, flexible PCBs (Printed Circuit Boards) are becoming a game-changer. If you're wondering how flexible PCB design for robotics can enhance your projects, the answer lies in their ability to adapt to complex shapes, save space, and withstand dynamic movements. However, designing these boards also comes with unique challenges like material selection and bending constraints. In this comprehensive guide, we'll dive deep into the advantages and challenges of using flexible PCBs in robotics applications, focusing on key aspects like materials, bending radius, dynamic flexing, and assembly techniques.

What Are Flexible PCBs and Why Are They Vital for Robotics?

Flexible PCBs, often called flex PCBs, are thin, lightweight circuit boards made from materials that allow them to bend and fold without breaking. Unlike traditional rigid PCBs, flex PCBs can conform to various shapes, making them ideal for robotics where space is limited, and movement is constant. In robotics applications, these boards are used in everything from robotic arms to wearable devices, enabling compact designs and reliable performance.

The importance of flexible PCB design in robotics cannot be overstated. Robots often require intricate wiring in tight spaces, and flex PCBs provide a solution by reducing the need for bulky connectors and cables. Their ability to handle dynamic flexing—repeated bending during operation—also makes them perfect for moving parts like joints or sensors.

Advantages of Flexible PCB Design in Robotics

Flexible PCBs offer several benefits that make them a top choice for robotics engineers. Let’s explore these advantages in detail.

1. Space-Saving and Lightweight Design

One of the biggest advantages of flex PCBs in robotics is their ability to save space. Robots often have limited internal room for components, especially in compact designs like drones or medical robots. Flexible PCBs can be folded or shaped to fit into tight spaces, reducing the overall footprint. Additionally, they are much lighter than rigid boards, which is crucial for robots where every gram affects energy efficiency and performance.

2. Enhanced Durability for Dynamic Flexing Applications

Robots are all about movement, and their components must endure constant bending and twisting. Flexible PCBs are designed for dynamic flexing applications, meaning they can handle thousands of bend cycles without failing. For instance, in a robotic gripper, a flex PCB can bend repeatedly as the gripper opens and closes, maintaining reliable electrical connections throughout.

3. Improved Signal Integrity and Reduced Wiring

Flexible PCBs minimize the need for multiple connectors and wires, which reduces signal loss and electromagnetic interference (EMI). In robotics, where precise control and fast data transmission are critical, this is a significant benefit. For example, a flex PCB can maintain signal integrity at speeds up to 10 Gbps in high-speed robotic vision systems, ensuring accurate real-time data processing.

4. Customizable Shapes for Complex Robotics Designs

Unlike rigid PCBs, flex PCBs can be tailored to fit the unique shapes of robotic components. Whether it’s wrapping around a cylindrical motor or fitting into the curved body of a humanoid robot, flexible PCB design for robotics allows for unparalleled customization. This adaptability leads to sleeker, more efficient designs.

Challenges in Designing Flexible PCBs for Robotics

While flexible PCBs bring numerous benefits, they also present unique challenges. Understanding these hurdles is essential for successful implementation in robotics applications.

1. Material Selection for Flex PCB Durability

Choosing the right flex PCB materials is critical but complex. Common materials like polyimide are popular due to their high thermal stability and flexibility, withstanding temperatures up to 400°C. However, not all materials are suitable for every robotic application. For instance, in underwater robots, materials must resist moisture and corrosion, while in industrial robots, they must endure high mechanical stress. Selecting the wrong material can lead to cracking or failure during dynamic flexing.

2. Bending Radius Constraints in Flex PCB Design

The bending radius of a flex PCB—how tightly it can be bent without damage—is a major design consideration. A smaller bending radius allows for more compact designs, but pushing beyond the material’s limits can cause cracks or delamination. For example, a typical polyimide-based flex PCB might have a minimum bending radius of 10 times its thickness (e.g., 0.5 mm for a 0.05 mm thick board). In robotics, where components move frequently, engineers must carefully calculate the bending radius to avoid long-term wear.

3. Complexity in Flex PCB Assembly

Assembling flexible PCBs is more challenging than rigid boards due to their delicate nature. Components must be placed precisely to avoid stress points during bending, and soldering must be done at lower temperatures to prevent damage to the flexible substrate. In robotics, where reliability is paramount, poor assembly can lead to connection failures, especially in high-vibration environments like autonomous vehicles.

4. Cost Considerations for High-Performance Designs

Flexible PCBs are often more expensive to produce than rigid ones due to specialized materials and manufacturing processes. For robotics projects with tight budgets, this can be a significant barrier. Additionally, testing for dynamic flexing applications requires advanced equipment to simulate thousands of bend cycles, further increasing costs.

Key Considerations for Flexible PCB Design in Robotics

To overcome the challenges and maximize the benefits of flex PCBs in robotics, engineers must focus on several design aspects. Below are actionable tips for creating reliable and efficient flexible PCB designs.

1. Optimize Material Selection for Specific Applications

When choosing flex PCB materials, consider the operating environment of the robot. For high-temperature applications, polyimide is a go-to choice due to its thermal resistance. For cost-sensitive projects, polyester might be a viable alternative, though it offers less durability. Always match the material’s properties to the robot’s needs, such as flexibility, tensile strength, and chemical resistance.

2. Design with Bending Radius in Mind

To prevent mechanical failure, design the flex PCB layout to minimize sharp bends. Use gradual curves and avoid placing components or vias in high-stress bending areas. Simulation software can help predict stress points and ensure the bending radius stays within safe limits, typically 6-10 times the board’s thickness for dynamic flexing applications.

3. Prioritize Robust Flex PCB Assembly Techniques

During assembly, use adhesives and reinforcement layers to protect critical areas of the flex PCB. Employ automated pick-and-place machines for precise component placement, reducing the risk of misalignment. Additionally, consider using strain relief features at connection points to prevent tearing during robotic movements.

4. Test for Dynamic Flexing Applications

Before deployment, subject the flex PCB to rigorous testing under real-world conditions. For instance, simulate 100,000 bend cycles to ensure reliability in a robotic joint. Testing should also account for environmental factors like temperature fluctuations and humidity, which can affect material performance in robotics applications.

Applications of Flexible PCBs in Robotics

Flexible PCBs are transforming various areas of robotics, enabling innovative designs and improved functionality. Here are some key applications where flex PCBs shine.

1. Robotic Arms and Joints

In robotic arms, flex PCBs connect sensors, motors, and controllers while accommodating constant movement at joints. Their ability to handle dynamic flexing ensures uninterrupted operation, even after millions of cycles.

2. Wearable Robotics and Exoskeletons

Wearable robots, such as exoskeletons for rehabilitation, rely on flex PCBs to conform to the human body’s contours. These boards provide lightweight, flexible connections between power sources and actuators, enhancing user comfort and mobility.

3. Autonomous Drones and Mobile Robots

In drones and mobile robots, space and weight are critical factors. Flexible PCBs reduce bulk by replacing traditional wiring, allowing for compact designs that improve flight time and maneuverability.

Future Trends in Flexible PCB Design for Robotics

The future of flexible PCB design in robotics is promising, with advancements in materials and manufacturing techniques on the horizon. Innovations like stretchable substrates could push the boundaries of dynamic flexing applications, allowing PCBs to stretch as well as bend. Additionally, the integration of embedded sensors directly into flex PCBs could enable smarter, more responsive robots.

Another trend is the use of eco-friendly materials for sustainable manufacturing. As robotics grows, so does the demand for greener production methods, and flex PCB materials are evolving to meet these needs without compromising performance.

Conclusion

Flexible PCB design for robotics offers unmatched advantages, from space-saving designs to durability in dynamic flexing applications. However, challenges like material selection, bending radius constraints, and assembly complexities require careful planning and expertise. By understanding these factors and following best practices, engineers can harness the full potential of flex PCBs to create cutting-edge robotic systems.

Whether you're designing a robotic arm, a wearable device, or an autonomous drone, flexible PCBs provide the adaptability and reliability needed for success. With continuous advancements in materials and technology, the role of flex PCBs in robotics will only grow, paving the way for more innovative and efficient designs.

ALLPCB

ALLPCB