What is Aluminum PCB?

An aluminum PCB, also known as an aluminium circuit board, has a similar layout to any other PCB. It has a layer or layers of copper, solder mask and silkscreen layered over it. Instead of having a fiberglass or plastic substrate, though, an aluminum circuit board has a metal substrate. This base mainly contains a combination of aluminum. The metal core can consist entirely of metal or have a combination of fiberglass and aluminum.

Aluminum PCBs typically are single sided, but can be double sided as well. Mulilayer aluminum circuit boards are highly difficult to manufacture.

Aluminum PCBs get the most use in LED and power converting electronics. The intense light produced by LEDs creates high levels of heat, which aluminum directs away from components. An aluminum core PCB extends the lifespan of an LED device and provides more stability. You can find aluminum substrates in street lights, stop lights and household lighting. They allow power converters to change currents and regulate electronics. Creators in many other industries also find use in aluminum circuit boards, but they don't implement them as often.

Why is Aluminium Used in Circuit Boards?

Aluminium is widely used in circuit board design because it effectively transfers heat away from critical components, minimizing the risks of overheating. The aluminium PCB manufacturing process results in boards that are not only thermally efficient but also stronger and more durable compared to fiberglass or ceramic substrates.

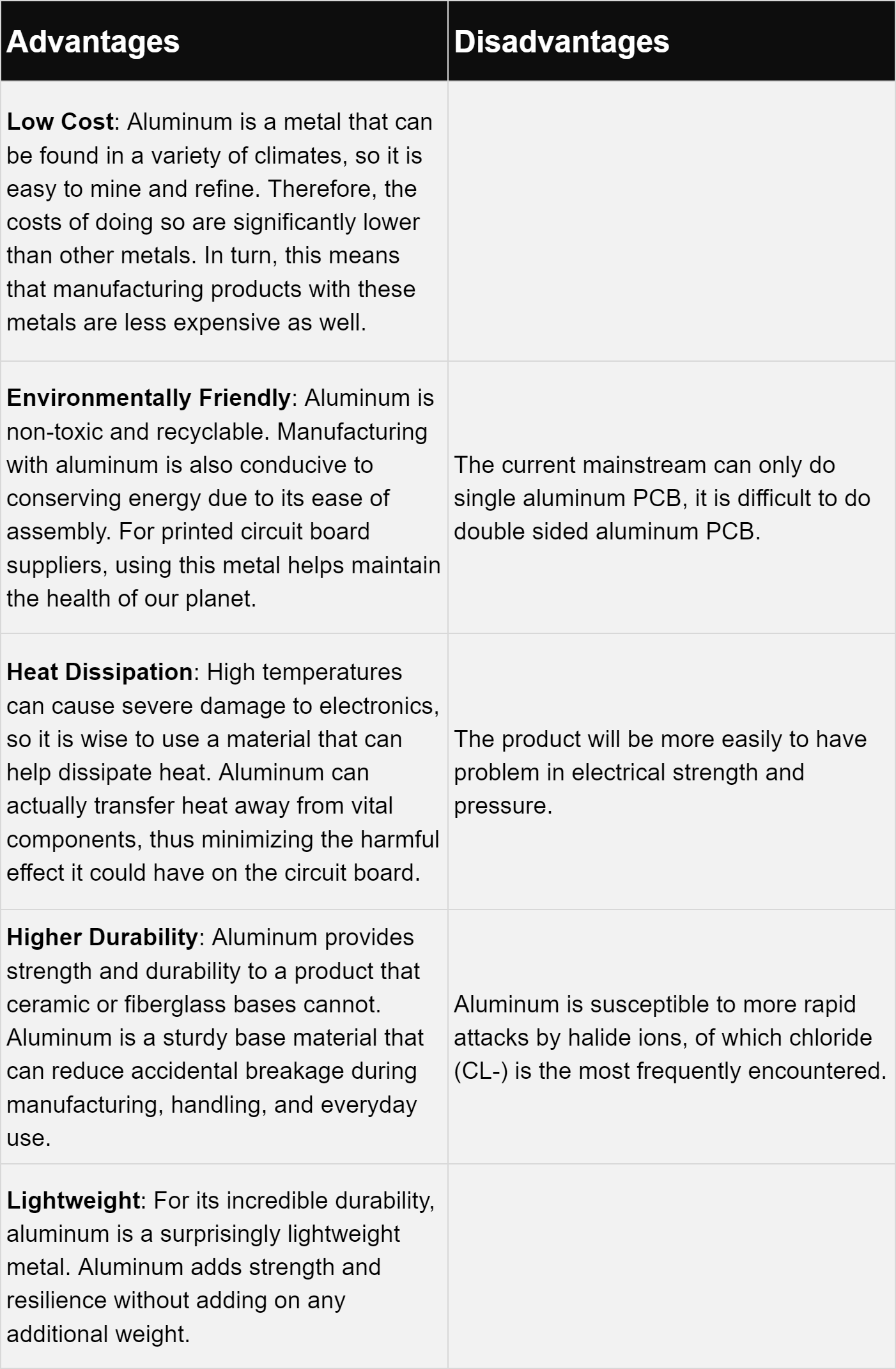

Advantages and Disadvantages of Aluminum PCB

Aluminum circuit boards are one of the most thermally conductive PCB options. They keep as much heat away from vital components as possible to ensure minimal circuit damage. Thanks to their high heat tolerance, they can handle higher density circuits and larger power levels. Aluminum substrates have a high level of physical durability that lowers the risk of breakage. Compared to other metals, aluminum has a lower environmental impact in addition to a reasonable cost.

On the other hand, aluminum PCBs tend to have more niche uses than standard boards. While they cost less than adding conductors to a copper board, they have a higher price than standard PCBs without those components. Investing in an aluminum core may not pay off if your application doesn’t involve high temperatures. If you plan on creating a flex circuit, flexible PCBs can only flex into its initial position. It will bend to fit into smaller electronics, but it won’t withstand the stress of vibration.

Aluminium PCB Design Guidelines

When following aluminium PCB design guidelines, engineers should pay attention to:

1. Thermal Dissipation

Common PCB substrates, such as PCB material FR4, CEM3 are poor conductors of thermal. If the heat of electronic equipments cannot be distributed in time, it will result in high temperature failure of electronic components. Aluminum substrates can solve this thermal dissipation problem.

Suggested Reading: Solving Heat Issues: How Aluminum PCBs Enhance Automotive Electronics

2. Thermal Expansion

Aluminum core PCB can effectively solve the thermal dissipation problem, so that the thermal expansion and contraction problem of components on printed circuit boards with different substances can be alleviated, which improves the durability and reliability of whole machine and electronic equipments. In particular, aluminum substrate can solve the SMT (surface mount technology) thermal expansion and contraction problems.

3. Dimensional Stability

Aluminum substrate printed circuit board has apparently higher stability than the insulating material of the printed circuit board. When heated from 30 ° C to 140 ~ 150 ° C, the dimensional change of aluminum substrate is only 2.5 ~ 3.0%.

4. Other Performance

Aluminum substrate printed circuit board has shielding effect, and can alternative brittle ceramic substrate. Aluminum substrate also helps to improve the heat resistance and physical properties and reduce production costs and labor.

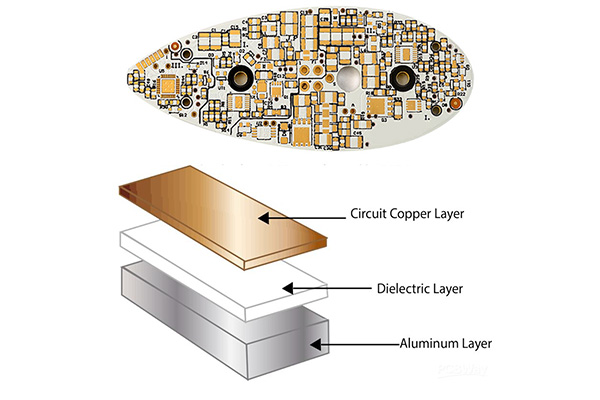

Structure of Aluminum PCB

Aluminum PCBs are aluminum based CCLs (CCL is a type of base material of PCBs). Aluminium PCBs are actually quite similar to FR4 PCBs. The basic structure of the Aluminum circuit board PCB is four layered. It consists of a layer of copper foil, a dielectric layer, an aluminum base layer and aluminum base membrane.

-

Copper Foil Layer: the copper layer used is relatively thicker than normal CCLs ( 1oz-10oz). A thicker layer of copper means a larger current carrying capacity.

-

Dielectric Layer: the Dielectric layer is a thermally conductive layer and is around 50μm to 200μm thick. It had a low thermal resistance and it suitable for its application.

-

Aluminum Base: The third layer isthe aluminum base which is made up of aluminum substrate. The aluminum core PCB has a high thermal conductivity.

-

Aluminum Base Membrane Layer: Aluminum base membrane is selective. It has a protective role by keeping the aluminum surface safe from scraping and unwanted etching. It is of two types i.e. Lower than 120 degree or around 250 degrees (anti high temperature).

Choosing the Right Dielectric Material for Aluminum PCBs

The dielectric layer in an aluminum PCB board is pivotal for determining thermal conductivity, electrical insulation, and breakdown voltage. Designers must evaluate trade-offs between dielectric thickness and thermal resistance, especially for high-power or high-density designs. Materials with higher W/m·K ratings (e.g., 2.0–3.0 W/m·K) provide better heat transfer, while thinner dielectrics reduce overall thermal impedance. At the same time, the dielectric must meet flame retardancy and dielectric strength standards like UL94V-0.

Learn More: How to Choose the Best Dielectric Material for Aluminum PCBs

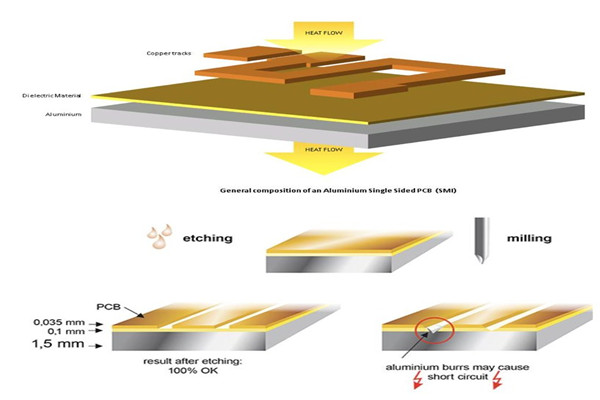

Aluminium PCB Manufacturing Process

The aluminium PCB manufacturing process is essentially the same. Here we will discuss the major manufacturing processes, the difficulties and their solutions.

-

Copper Etching: the copper foil used in Aluminum PCBs is comparatively thicker. If the copper foil is over 3oz however, the etching requires width compensation. If it is not according to the demand of the design, the trace width will be out of tolerance after etching. Therefore the trace width compensation should be designed accurately. The etching factors need to be controlled during manufacturing process.

-

Solder Mask Printing: due to the thick copper foil there is a difficulty in solder mask printing of aluminum core PCB. This is because if the trace copper is too thick then the image etched will have a large difference between trace surface and base board and solder mask printing will be difficult. Therefore, the two-time solder mask printing is used. The solder mask oil used should be of good quality and in some cases the resin filling is done first and then solder mask.

-

Mechanical Manufacturing: the mechanical manufacturing process involves mechanical drilling, molding and v-scoring etc. which Is left on internal via. This tends to reduce electrical strength. Therefore, the electric milling and professional milling cutter should be utilized for low-volume manufacturing of products. The drilling parameters should be adjusted to prevent burr from generating. This will help your mechanical manufacturing.

Real-World Case Studies

Aluminum circuit board PCBs are used in diverse industries—each with unique design challenges. In real-world applications, clients have achieved impressive thermal improvements by optimizing dielectric thickness, copper weight, and layout topology. For instance, a power LED module manufacturer reduced junction temperatures by over 20°C through customized aluminum PCB stack-ups. Another case involved a medical imaging company using multilayer aluminum boards to maintain thermal and electrical isolation in compact footprints.

Explore More: Real-World Examples: Aluminum PCB Case Studies

Applications of Aluminum PCBs in High-Power Systems

Aluminum PCBs are widely used across industries where high power and heat management are critical. Some common applications include:

1. LED Lighting Systems: High-intensity LEDs generate significant heat, and aluminum core PCBs help dissipate it efficiently, maintaining brightness and longevity.

2. Power Electronics: Power converters, inverters, and amplifiers require stable thermal platforms, making aluminum PCBs ideal.

Read More: Boosting Performance: The Role of Aluminum PCBs in Power Electronics

3. Automotive Electronics: From headlights to battery management systems, automotive-grade aluminium PCBs help with high reliability and resistance to vibration and heat.

4. Medical Devices: Precision instruments like imaging scanners, wearable monitors, and surgical tools depend on consistent thermal control.

Read More: Aluminum PCB in Medical Devices: Ensuring Reliability and Safety

5. Aerospace and Defense: These industries demand performance in extreme environments—aluminium PCB boards provide high durability and thermal stability.

Read More: Aluminum PCB in Aerospace: Performance Under Pressure

8. Switches, microwave: radiator, semiconductor devices, thermal insulation and motor controller.

9. Industrial vehicles: ignition, voltage regulator, automatic safety control system, lighting conversion system.

Read More: Why High-Power Applications Demand Aluminum PCBs

ALLPCB: A Reliable Aluminum PCB Manufacturer

ALLPCB, one of the leading aluminum PCB manufacturers in China. ALLPCB offers one-stop services for electronic manufacturing, including PCB fabrication, components sourcing, SMT, and assembly.

ALLPCB has been manufacturing aluminum PCBs for decades. Our full-feature aluminum circuit board capabilities and Free DFM Check allow you to get high-quality aluminium circuit boards done within your custom PCB cost targets. Our expertise in aluminium PCB design and manufacturing ensures reliable performance in LED, power, and automotive industries. With the new user promotion, you can get Aluminum PCB prototype for only 1$. Get quote today to start!

ALLPCB

ALLPCB