In the fast-evolving world of power electronics, managing heat and ensuring reliable performance are top priorities. Aluminum PCBs (Printed Circuit Boards) have emerged as a game-changer for applications like power supplies, inverters, and amplifiers. But how exactly do they boost performance? Aluminum PCBs excel in thermal management, handle high currents, and provide durability, making them ideal for demanding power electronics projects.

In this blog, we’ll dive deep into the unique advantages of aluminum PCBs, exploring their role in enhancing efficiency and reliability across various applications. Whether you’re designing an aluminum PCB power supply or working on a power amplifier PCB, you’ll discover why this technology is a must-have for modern electronics.

Why Aluminum PCBs Are Essential for Power Electronics

Power electronics deal with high voltages, currents, and heat, which can degrade performance or damage components if not managed properly. Traditional FR4 PCBs, made of fiberglass, often struggle to dissipate heat effectively in these scenarios. This is where aluminum PCBs shine. With a metal core, typically aluminum, these boards offer superior thermal conductivity, ensuring heat is quickly transferred away from sensitive components.

For instance, in high-power applications, aluminum PCBs can reduce operating temperatures by up to 20-30°C compared to standard materials, extending the lifespan of components. Their ability to handle heat makes them a top choice for industries like automotive, renewable energy, and industrial automation.

Suggested Reading: Why High-Power Applications Demand Aluminum PCBs

Key Benefits of Aluminum PCBs in Thermal Management for Power Electronics

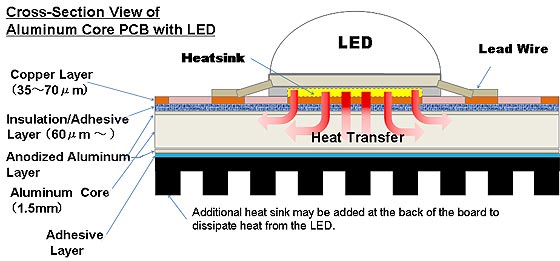

One of the standout features of aluminum PCBs is their role in PCB thermal management for power electronics. Heat dissipation is critical in devices that operate under high power, as excessive heat can lead to component failure or reduced efficiency. Aluminum’s thermal conductivity, often around 1-2 W/mK for the dielectric layer combined with the metal base, far surpasses that of traditional PCB materials.

This means that in applications like LED lighting or motor drives, aluminum PCBs can keep temperatures in check, preventing thermal throttling. For example, in a power supply circuit, maintaining a stable temperature can improve efficiency by up to 10%, reducing energy waste. Additionally, their lightweight yet robust structure adds to their appeal, balancing performance with practicality.

Durability Under Stress

Beyond heat dissipation, aluminum PCBs are built to last. They resist vibration and mechanical stress better than standard boards, which is crucial in rugged environments like automotive or industrial systems. Their durability ensures consistent performance even under challenging conditions, reducing the need for frequent replacements.

Aluminum PCB Power Supply: Efficiency and Reliability Combined

When it comes to designing an aluminum PCB power supply, the benefits are clear. Power supplies convert and regulate electricity, often generating significant heat in the process. Aluminum PCBs help manage this heat, ensuring stable operation and preventing overheating-related failures.

For instance, in a switch-mode power supply handling 50W or more, an aluminum PCB can maintain lower junction temperatures for transistors and diodes, improving overall efficiency. This translates to less energy loss—sometimes as much as a 5-8% improvement in efficiency compared to traditional boards. The result is a more reliable power supply that performs consistently over time.

Applications in Real-World Scenarios

Aluminum PCBs are widely used in power supplies for renewable energy systems, such as solar converters. These systems often operate outdoors, exposed to temperature fluctuations. The thermal stability of aluminum ensures that the power supply remains operational, even in harsh conditions, supporting uninterrupted energy conversion.

Suggested Reading: Real-World Examples: Aluminum PCB Case Studies

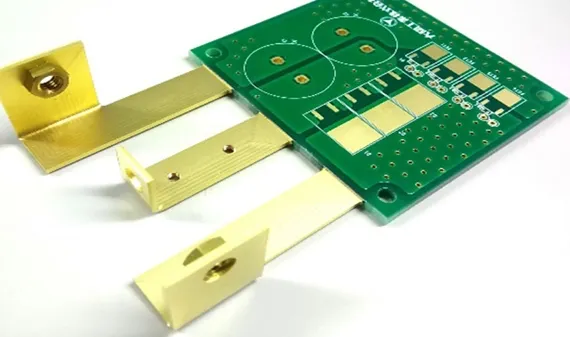

High Current Aluminum PCB: Handling Power with Ease

For circuits that demand high current, such as those in industrial machinery or electric vehicles, a high current aluminum PCB is a perfect fit. The aluminum base provides a low thermal resistance path, allowing the board to handle currents upwards of 10A without overheating. This capability is essential for maintaining performance in high-demand scenarios.

In practical terms, a high current aluminum PCB can support thicker copper layers—often up to 4oz or more—without compromising on heat dissipation. This makes it ideal for applications where both power and reliability are non-negotiable. For example, in battery management systems, these boards ensure safe and efficient power distribution, even under heavy loads.

Aluminum PCB for Inverters: Powering Renewable Energy Solutions

Inverters, which convert DC to AC power, are at the heart of renewable energy systems like solar and wind power setups. An aluminum PCB for inverters offers the thermal management and durability needed to handle the high power levels involved. Inverters often operate at efficiencies above 90%, and any heat buildup can reduce this figure significantly.

Aluminum PCBs help maintain high efficiency by dissipating heat from power transistors and other components. In a typical 5kW solar inverter, using an aluminum PCB can lower the operating temperature by 15-25°C, ensuring optimal performance and extending the system’s lifespan. This reliability is critical for off-grid or hybrid systems where consistent power delivery is a must.

Enhanced Design Flexibility

Aluminum PCBs also allow for compact inverter designs. Their ability to manage heat means components can be placed closer together without risking thermal issues. This leads to smaller, lighter inverters that are easier to install and maintain, especially in space-constrained environments.

Power Amplifier PCB: Achieving Clarity and Efficiency

In audio systems and radio frequency applications, a power amplifier PCB built with aluminum offers unmatched performance. Power amplifiers generate significant heat, especially in high-output scenarios like professional audio equipment or broadcasting systems. Without proper PCB thermal management, this heat can distort sound quality or damage components.

Aluminum PCBs address this by efficiently dissipating heat, ensuring clean signal amplification. For example, in a 100W audio amplifier, an aluminum PCB can reduce thermal noise, leading to clearer sound output. Additionally, their mechanical strength protects against vibrations, which is vital for portable or vehicle-mounted audio systems.

Design Considerations for Aluminum PCBs in Power Electronics

While aluminum PCBs offer numerous benefits, designing them for power electronics requires careful planning. Here are some key factors to keep in mind:

- Dielectric Layer Thickness: The insulating layer between the aluminum base and copper circuit must balance thermal conductivity and electrical isolation. A thickness of 0.075-0.15mm is often ideal for most high-power applications.

- Copper Weight: For high current designs, opt for heavier copper weights (2oz or more) to handle the load without excessive heat buildup.

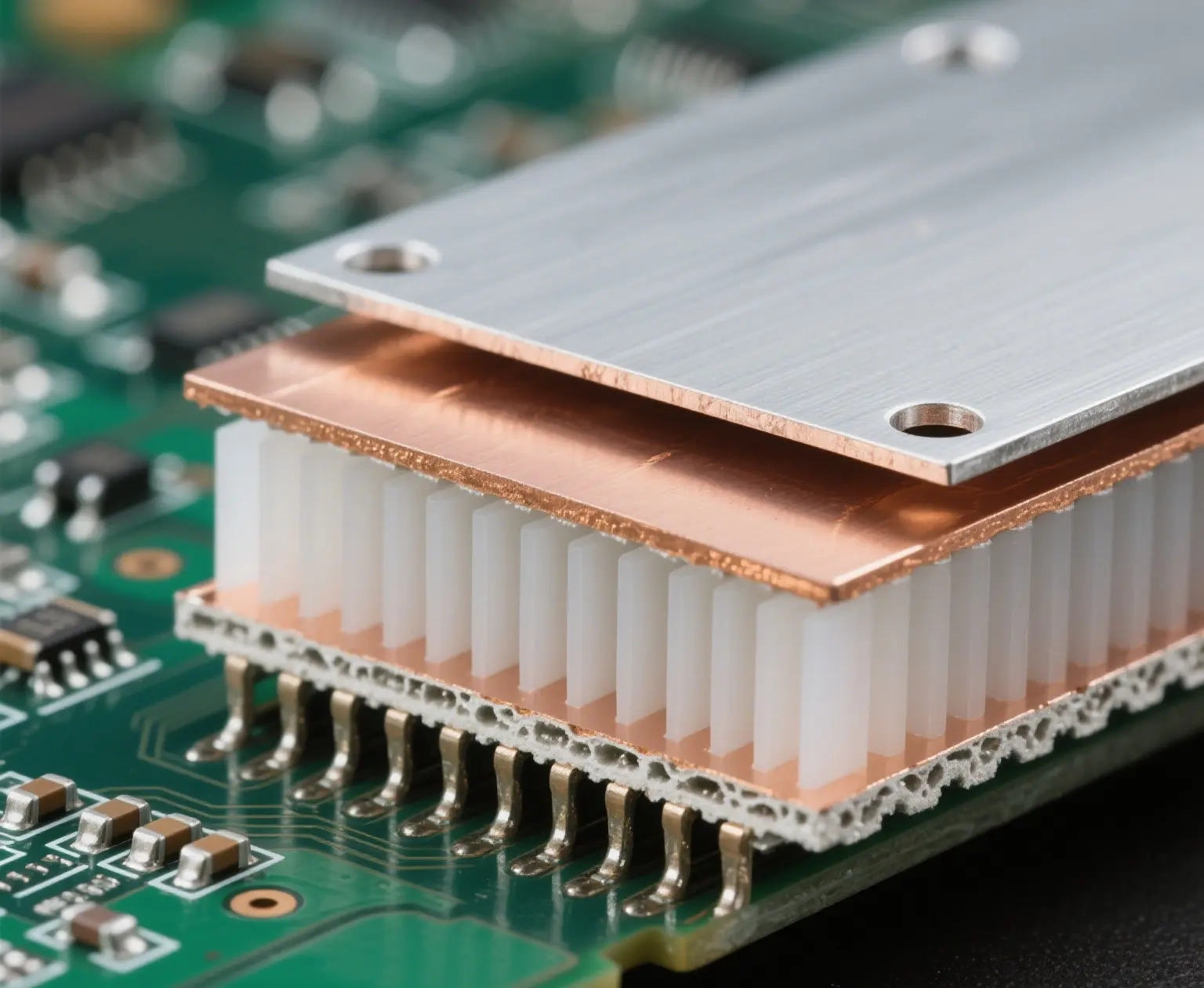

- Heat Sink Integration: Pairing aluminum PCBs with external heat sinks can further enhance thermal management, especially in inverters or power supplies exceeding 100W.

- Component Placement: Place heat-generating components strategically to maximize heat dissipation through the aluminum base.

By addressing these factors, you can optimize the performance of aluminum PCBs in any power electronics project.

Comparing Aluminum PCBs to Other Materials

To fully appreciate the value of aluminum PCBs, it’s helpful to compare them with other materials commonly used in power electronics:

- FR4 PCBs: While cost-effective, FR4 boards have poor thermal conductivity (around 0.3 W/mK), making them unsuitable for high-power applications. Aluminum PCBs, with thermal conductivity often exceeding 1 W/mK, outperform FR4 in heat dissipation by a wide margin.

- Ceramic PCBs: The ceramic PCB offer excellent thermal performance but are brittle and expensive. Aluminum PCBs provide a more cost-effective and durable alternative without sacrificing much on thermal management.

- Copper Core PCBs: Copper-based boards have higher thermal conductivity than aluminum but are heavier and more expensive. Aluminum strikes a better balance for most applications, offering lightweight construction at a lower cost.

This comparison highlights why aluminum PCBs are often the preferred choice for balancing performance, cost, and reliability in power electronics.

Future Trends: Aluminum PCBs in Emerging Technologies

As power electronics continue to evolve, aluminum PCBs are poised to play a pivotal role in emerging technologies. Electric vehicles (EVs), for instance, rely heavily on efficient power management systems, where aluminum PCBs can handle the high currents and heat generated by battery packs and motor controllers. Similarly, in 5G infrastructure, power amplifiers and base stations benefit from the thermal stability of aluminum PCBs to maintain signal integrity.

Advancements in PCB manufacturing are also making aluminum PCBs more accessible. Improved dielectric materials and fabrication techniques are reducing costs while enhancing performance, opening doors for wider adoption in consumer electronics and IoT devices.

Conclusion: Unleashing the Potential of Aluminum PCBs

Aluminum PCBs are revolutionizing power electronics by addressing critical challenges like heat dissipation, high current handling, and durability. Whether you’re working on an aluminum PCB power supply, a high current aluminum PCB, or an aluminum PCB for inverters, this technology offers the performance boost needed to stay ahead in demanding applications. Their role in thermal management for power electronics ensures reliability, while their versatility supports innovations in fields like renewable energy and audio systems with a power amplifier PCB.

By choosing aluminum PCBs, engineers can design systems that are not only efficient but also built to last. As technology advances, these boards will continue to be a cornerstone of high-performance electronics, driving progress across industries. If you’re looking to elevate your next project, consider the unmatched benefits of aluminum PCBs for superior results.

ALLPCB

ALLPCB