When working on electronics design or developing a custom hardware project, one of the first challenges is figuring out the custom PCB board cost. The pcb board price per unit directly affects your budget, design decisions, and time to market. For startups and engineers alike, understanding the true custom circuit board cost can make the difference between a smooth launch and unexpected expenses.

This guide breaks down the key factors that influence PCB cost per unit — from board size, materials, and layer count, to order volume and lead time. We’ll also compare prototype vs. mass production pricing, share proven cost-saving tips, and explain how manufacturers like ALLPCB help engineers worldwide with special offers such as $1 PCB prototyping and free global shipping. By the end, you’ll have a clear framework to estimate costs and optimize your next PCB project efficiently.

What is Custom PCB Cost Per Unit?

The cost per unit of a custom PCB refers to the price you pay for each board when ordering from a manufacturer. Unlike mass-produced boards, custom PCB board cost depends on unique design requirements, specialized materials, and chosen finishes.

Understanding these factors is crucial whether you’re creating prototypes or scaling up to large production. By calculating your custom circuit board cost correctly, you avoid budget overruns and can plan for future manufacturing needs.

Key Factors Influencing Custom PCB Cost Per Unit

Several elements affect the cost per unit for custom PCBs:

Board Size and Layer Count:

- Size: Larger boards require more raw material and take longer to manufacture, which increases the cost.

- Layer Count: Larger boards require more materials, while multi-layer PCBs (e.g., 4, 6, or 8 layers) are more complex and increase PCB board price.

Material Type:

- Standard FR4 is cost-effective, but high-performance materials like Rogers or ceramic can raise custom circuit board cost significantly.

Production Volume:

- Low-volume orders (e.g., 5–10 units) are generally more expensive per unit because of setup and tooling fees.

- High-volume orders save money by spreading fixed costs over more units. This usually lowers the custom PCB board cost for each unit.

Design Complexity:

- Trace Width and Spacing: Fine trace widths and close spacing require precise manufacturing, which can raise the unit price.

- Hole Sizes: Complex designs with small drilled holes or vias (through-hole connections) increase production difficulty, impacting the PCB board price.

Surface Finish and Coating:

- Common finishes like HASL (Hot Air Solder Leveling) are cheap. However, advanced finishes like ENIG (Electroless Nickel Immersion Gold) cost more. ENIG improves durability and is better for lead-free and high-reliability uses.

Lead Time:

- The faster you need your PCBs, the higher the cost. Many manufacturers offer expedited services at a premium PCB board price to meet urgent deadlines.

Custom PCB Cost Per Unit: Typical Pricing Ranges

Below is a general pricing guide based on common PCB configurations. Keep in mind these are rough estimates and actual costs will vary based on specific requirements and manufacturers.

- Single-Layer PCBs: For a simple, single-layer PCB, the custom circuit board cost per unit can range from $1 to $5 for low volumes. Bulk orders could bring this down to below $1 per unit.

- Double-layer PCBs typically cost between $1 and $10. The PCB board price depends on the design and the size of the order.

- Multi-Layer PCBs: A 4-layer PCB can range from $10 to $20 per unit for small quantities, while bulk orders may reduce this price by 20–50%.

- Advanced PCBs: For boards made with advanced materials or unique design requirements, the custom circuit board cost per unit could easily exceed $50, even for bulk orders.

Tips to Reduce Custom PCB Cost Per Unit

If you're aiming to minimize your custom PCB cost per unit without compromising too much on quality, here are some strategies:

- Design for Standard Specifications: Avoid custom sizes and unusual layer counts if possible. Stick to standard trace widths and spacing to keep manufacturing simple and cost-effective.

- Optimize Board Layout: Consolidate components and reduce board size where possible. A smaller board with fewer layers and standard spacing can significantly reduce your per-unit costs.

- Order in Bulk: Larger orders typically lead to a lower unit price. If you anticipate needing multiple boards, consider ordering them together to benefit from volume discounts.

- Choose Standard Finishes and Materials: Unless your design demands it, standard materials (like FR4) and finishes (such as HASL) can keep costs lower.

- Extend Lead Times: If your project allows for it, choosing a standard lead time instead of expedited manufacturing will generally save you money.

Cost Comparison: PCB Prototype vs Mass Production

Many engineers overlook the fact that pcb board price per unit drops dramatically when moving from prototypes to bulk orders.

-

Prototype Stage (1–10 pcs): Higher per-unit custom PCB board cost due to setup fees.

-

Medium Volume (50–100 pcs): Per-unit cost decreases by 30–50%.

-

Mass Production (1000+ pcs): The lowest pcb board price, ideal for consumer electronics.

Why Choose the Right PCB Manufacturer Matters

Selecting the right PCB manufacturer plays a big role in the final cost and quality of your boards. Here are a few qualities to look for:

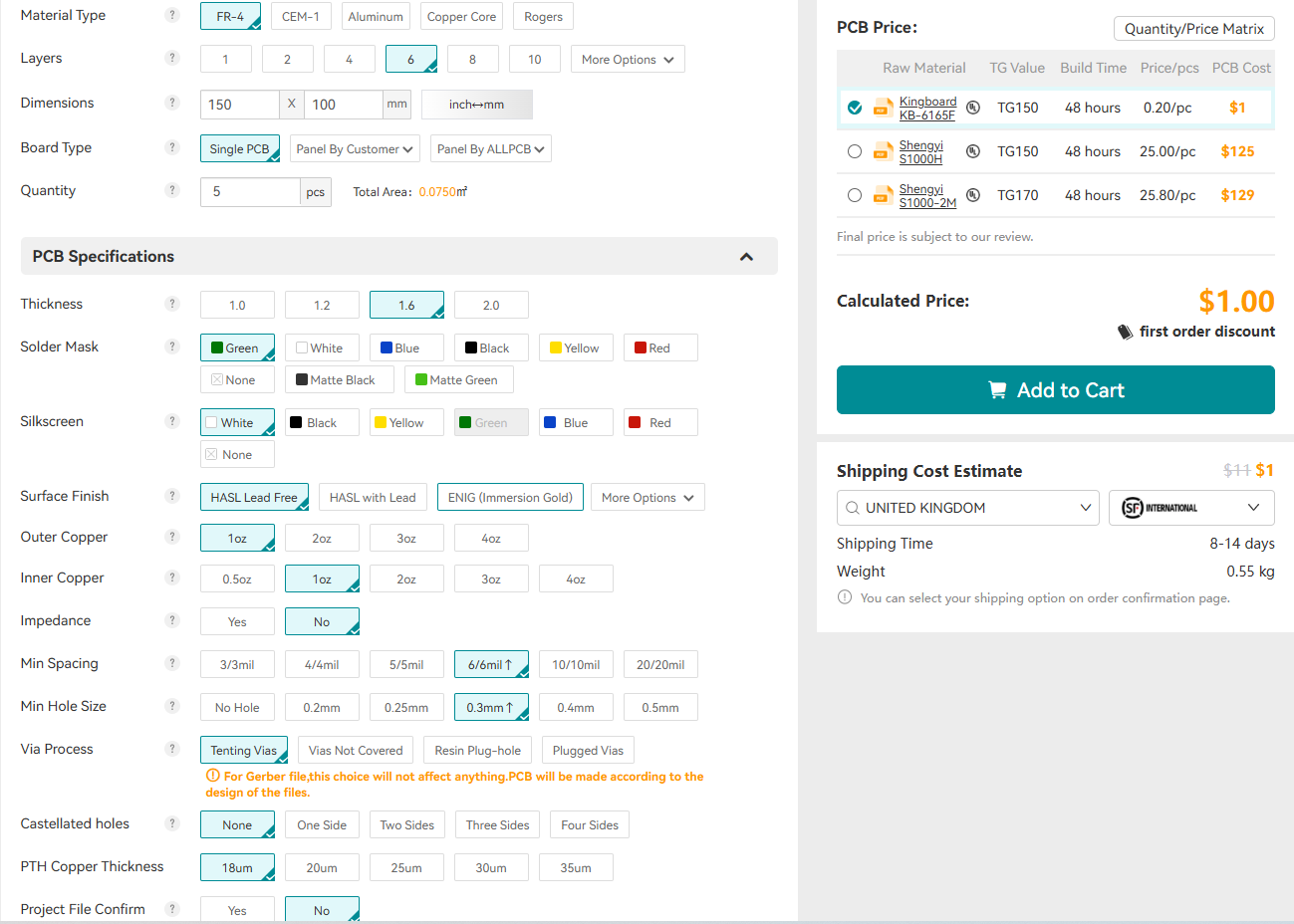

- Transparency: A good manufacturer provides a clear breakdown of costs with no hidden fees. ALLPCB's online quote system will give you an accurate estimate of your cost. You can try out different parameters to compare the price differences

- Quality Assurance: Trusted manufacturers follow strict quality standards. They provide guarantees or warranties, so you get what you pay for. ALLPCB follows IPC-A-600G, IPC-6012, IATF 16949 and other industry standards, using stringent quality control measures to ensure your PCBs meet all requirements.

- Experience and Expertise: Look for a manufacturer with a proven track record in the industry. Experienced manufacturers are more likely to understand the complexities of your project and can offer valuable insights. ALLPCB has years of experience and a team of experts who can help optimize your designs for better performance.

- Customer Support: Excellent customer service is essential when working with a PCB manufacturer. You want a team that is responsive and ready to assist you with any questions or concerns. ALLPCB offers dedicated 24-hour support to guide you through the entire process, from file audit to delivery.

How to Calculate Your Custom PCB Cost Per Unit

To get an accurate cost estimate for your custom PCB, many manufacturers offer an online PCB quote calculator. You can enter your board details and see the custom PCB board cost right away. Here’s a basic approach to help you estimate:

- Input Your Dimensions and Layers: Enter the board size and the number of layers. For a standard 2-layer board, you’ll likely get a base price, which will increase with additional layers.

- Select Material and Finish Options: Choose your preferred materials (e.g., FR4, Rogers) and finishes (HASL, ENIG). Each choice here will impact the final cost.

- Adjust Order Quantity: Notice how the custom circuit board cost per unit decreases with a higher quantity. Often, manufacturers offer better rates when ordering in bulk.

- Choose Lead Time: If you have a flexible schedule, choosing a longer lead time can lower the PCB board price significantly. Rush orders typically incur higher fees.

Unlock $1 PCB Prototyping & Free Shipping Worldwide from ALLPCB

To make PCB prototyping more affordable for global engineers, ALLPCB has recently launched a special $1 campaign. This campaign is designed to help makers, startups, and hardware developers reduce custom PCB board cost at the earliest stage of product development. With just $1, you can order prototype boards that normally cost far more on the market.

-

$30 Off Your First Order

New users instantly receive $30 off their first order plus an extra $30 shipping discount. There are no restrictions — any board size, specification, or quantity applies. -

Free Global Shipping

ALLPCB covers up to $30 in international shipping fees, meaning your prototype can be delivered worldwide at zero cost to you. -

No Limits on PCB Specs

Whether you need 2-layer, 4-layer, or even 6-layer designs, there are no limitations on PCB size, color, or layers. This ensures your custom circuit board cost remains low while maintaining full design freedom.

Conclusion

Knowing the custom PCB cost per unit can help you plan and budget well. This is important for both prototypes and large-scale production. By understanding the factors affecting PCB costs and implementing cost-saving tips, you can optimize your project without overspending.

When you are ready to create your custom PCB design, use a trusted manufacturer’s online quote tool. ALLPCB will give you an accurate and detailed custom PCB board cost estimate for your project. With the right choices and partners, you’ll be able to balance quality and budget seamlessly.

ALLPCB

ALLPCB