Are you considering a black solder mask for your next PCB design but unsure if it’s the right choice? Black solder masks offer a sleek, modern look while providing essential protection for your circuit board. However, their functionality, especially regarding heat dissipation and visibility, often raises questions. In this comprehensive guide, we’ll explore the balance between solder mask aesthetics and practicality, diving into topics like black solder mask heat management, benefits of a black PCB solder mask, and the advantages of a high contrast solder mask. Let’s break it down so you can make an informed decision for your project.

What Is a Solder Mask and Why Does Color Matter?

A solder mask is a thin protective layer applied to a printed circuit board (PCB) to shield copper traces from oxidation, prevent solder bridges during assembly, and protect against environmental damage. While its primary role is functional, the color of the solder mask also plays a significant part in both aesthetics and practicality.

Traditionally, green has been the standard color for solder masks due to its high contrast with copper traces and white silkscreen, making it easy to inspect for defects. However, colors like black, blue, red, and white have gained popularity for their unique visual appeal and specific use cases. Among these, the black PCB solder mask stands out for its modern, professional appearance, often used in high-end electronics and consumer-facing products. But how does it stack up in terms of functionality? Let’s dive deeper.

The Aesthetic Appeal of Black Solder Mask

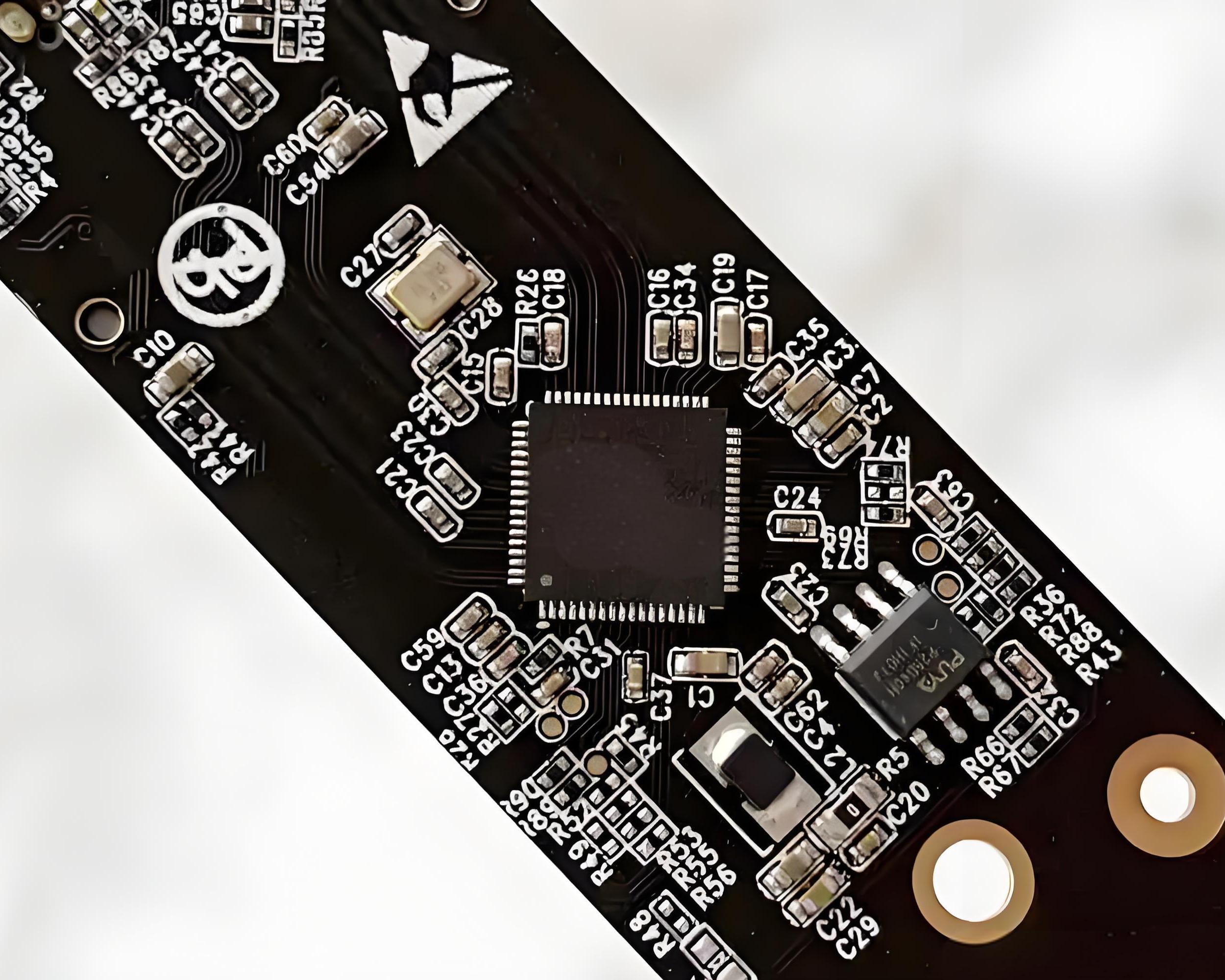

When it comes to solder mask aesthetics, black is often the go-to choice for designers aiming for a premium look. Its dark, matte finish gives PCBs a clean, sophisticated appearance, making it a popular option for consumer electronics like smartphones, gaming consoles, and audio equipment. The black background also enhances the visibility of branding or logos printed in white or metallic silkscreen, creating a striking visual effect.

Beyond looks, a black solder mask can help hide minor imperfections or scratches on the board, maintaining a polished appearance even after handling or assembly. For products where the PCB is visible to the end user, such as in open-case designs or transparent enclosures, a black PCB solder mask can elevate the overall design language of the product.

However, aesthetics isn’t just about looks—it can also influence perception. A black solder mask often conveys a sense of high quality and cutting-edge technology, which can be a subtle but powerful marketing tool for manufacturers targeting tech-savvy audiences.

Functionality of Black Solder Mask: Heat Management and Beyond

While aesthetics are important, functionality remains the core purpose of a solder mask. One of the most discussed topics surrounding black solder masks is their performance in heat dissipation, often searched as black solder mask heat. Let’s break this down with a focus on practical insights.

Heat Absorption and Dissipation

Black surfaces are known to absorb more heat compared to lighter colors due to their low reflectivity. In PCB applications, this can be a double-edged sword. On one hand, a black solder mask may absorb more heat from components or external sources, potentially raising the board’s temperature. Studies suggest that black surfaces can absorb up to 95% of incoming light and heat, compared to only about 10-20% for white surfaces.

However, this heat absorption doesn’t necessarily translate to poor performance. The solder mask layer is thin (typically 0.8 to 1.2 mils or 20-30 micrometers), and its impact on overall heat dissipation is minimal compared to the PCB substrate material, copper thickness, and component placement. Most heat in a PCB is dissipated through copper layers and thermal vias, not the solder mask. Therefore, while a black PCB solder mask might slightly increase surface temperature under direct sunlight or high ambient conditions, it’s unlikely to significantly affect the board’s thermal performance in typical indoor or enclosed environments.

For high-power applications where heat is a concern, designers can mitigate any minor effects by optimizing the board layout, using thermal pads, and ensuring proper airflow. In short, the heat absorption of a black solder mask is a valid consideration but rarely a dealbreaker.

Protection and Durability

Functionally, a black solder mask offers the same level of protection as other colors. It prevents solder bridges, shields copper traces from corrosion, and provides insulation against environmental factors like humidity and dust. The material used for black solder masks, typically a liquid photoimageable (LPI) epoxy, is formulated to withstand the rigors of PCB assembly and operation, including temperatures up to 260°C during reflow soldering.

High Contrast Solder Mask: Visibility and Inspection

One of the standout functional benefits of a black solder mask is its ability to serve as a high contrast solder mask. When paired with a white or yellow silkscreen, a black background makes text, symbols, and component outlines highly visible. This high contrast is especially valuable during manual inspection or troubleshooting, where clear labeling can save time and reduce errors.

For automated optical inspection (AOI) systems, however, the contrast between a black solder mask and copper pads can sometimes pose challenges. AOI cameras rely on color differentiation to detect defects, and a black mask may reduce visibility of certain features compared to a green or blue mask. To address this, manufacturers often adjust camera settings or use specialized lighting to ensure accurate detection. In practice, with modern equipment, this is rarely a significant issue.

For engineers and designers, the high contrast of a black solder mask also aids in debugging prototypes. Identifying components and tracing connections becomes easier when markings stand out clearly against the dark background. This visibility can be a subtle but meaningful advantage in fast-paced development cycles.

Comparing Black Solder Mask to Other Colors

To fully understand the trade-offs of choosing a black solder mask, it’s helpful to compare it with other common colors in terms of aesthetics and functionality.

- Green: The traditional choice, offering excellent contrast for inspection but often seen as outdated or less visually appealing. It has minimal heat absorption compared to black.

- Blue: A middle ground between aesthetics and functionality, with moderate contrast and a modern look. Heat absorption is lower than black but higher than green.

- Red: Eye-catching and often used for branding, but it can make silkscreen text harder to read and absorbs heat similarly to black.

- White: Reflects heat effectively and looks clean, but it shows dirt and scratches easily, and contrast with silkscreen can be poor unless black ink is used.

Black stands out for its balance of premium aesthetics and practical contrast, making it a versatile choice for many applications. However, for projects where heat dissipation is critical—such as outdoor electronics exposed to direct sunlight—a lighter color might be worth considering.

Applications Best Suited for Black Solder Mask

Given its unique blend of style and functionality, a black PCB solder mask is particularly well-suited for specific applications:

- Consumer Electronics: Products like smartphones, wearables, and audio devices benefit from the sleek look of black, especially when the PCB is visible to users.

- Automotive Displays: In dashboards and infotainment systems, black solder masks complement the modern interior design while providing high contrast for labeling.

- Prototyping and Development: Engineers often prefer black for prototypes due to its clear visibility of silkscreen markings during testing.

- High-End Industrial Equipment: For machinery where branding and appearance matter, black adds a professional touch.

For applications involving extreme heat or outdoor exposure, such as solar inverters or LED lighting in direct sunlight, designers should weigh the minor heat absorption of black against other colors and complement it with robust thermal management strategies.

Design Tips for Using Black Solder Mask

If you’ve decided to go with a black solder mask, here are some practical tips to maximize both its aesthetic and functional benefits:

- Pair with High-Contrast Silkscreen: Use white or yellow silkscreen ink to ensure markings are legible. This enhances the high contrast solder mask effect for both human and machine inspection.

- Optimize for Thermal Management: If black solder mask heat absorption is a concern, incorporate thermal vias, heat sinks, and proper component spacing to manage temperature effectively.

- Consider Matte Finish: A matte black solder mask reduces glare and fingerprints, maintaining a clean look over time.

- Test for AOI Compatibility: Work with your manufacturer to ensure automated inspection systems are calibrated for a black mask, avoiding potential oversight of defects.

Conclusion: Striking the Right Balance

Choosing a solder mask color is a decision that goes beyond mere appearance—it’s about finding the right balance between solder mask aesthetics and functionality. A black PCB solder mask offers a compelling mix of sleek, modern design and practical benefits like high contrast visibility. While concerns about black solder mask heat absorption are valid, they are often overstated and can be managed with proper design techniques.

For many applications, especially in consumer electronics and prototyping, the advantages of a black solder mask—both visual and functional—make it an excellent choice. By understanding its strengths and limitations, you can leverage this color to enhance your PCB design while ensuring reliable performance.

At ALLPCB, we’re committed to helping you bring your vision to life with high-quality PCB solutions tailored to your needs. Whether you’re drawn to the striking look of a high contrast solder mask or need guidance on thermal considerations, our team is here to support every step of your project. Explore the possibilities with a black solder mask and elevate your next design.

ALLPCB

ALLPCB