If you're involved in surface mount technology (SMT) assembly, you know that the quality of solder paste printing can make or break your production process. A key factor in achieving consistent, high-quality prints is proper SMT stencil care. So, how do you ensure optimal performance? It all comes down to regular cleaning, diligent maintenance, and following best practices for stencil handling and storage. In this comprehensive guide, we'll dive deep into the essentials of SMT stencil care, covering everything from stencil cleaning and aperture cleaning to maintenance tips and best practices for flawless solder paste printing.

Why SMT Stencil Care Matters in Solder Paste Printing

In SMT assembly, the stencil is the heart of the solder paste printing process. It acts as a template, guiding the precise application of solder paste onto the printed circuit board (PCB) before components are placed. If the stencil isn't clean or well-maintained, issues like uneven paste deposits, bridging, or insufficient solder can arise, leading to defects. Studies suggest that nearly 70% of SMT defects are linked to poor solder paste application, often due to neglected stencil care. By prioritizing stencil maintenance, you can reduce waste, improve production quality, and extend the lifespan of your stencil by up to 30%.

Let's explore the critical aspects of SMT stencil care to help you achieve optimal printing results every time.

What Is an SMT Stencil and Its Role in PCB Assembly?

An SMT stencil is a thin sheet, typically made of stainless steel, with laser-cut or chemically etched apertures (openings) that match the PCB's pad layout. During the printing process, solder paste is pushed through these apertures using a squeegee, depositing the paste onto the board in precise locations. The accuracy of this process depends on the stencil's condition—clogged apertures or damaged surfaces can lead to misprints, affecting the entire assembly line.

Key Challenges in SMT Stencil Performance

Before diving into care techniques, it's important to understand the common issues that can compromise stencil performance during solder paste printing:

- Clogged Apertures: Residual solder paste can dry and block openings, leading to incomplete or uneven deposits.

- Wear and Tear: Repeated use and improper handling can cause scratches or deformation, reducing precision.

- Contamination: Dust, oils, or other residues on the stencil surface can interfere with paste release.

- Improper Storage: Stencils left exposed to harsh environments can corrode or get damaged.

Addressing these challenges through proper cleaning and maintenance is essential for consistent results.

Best Practices for SMT Stencil Cleaning

Regular stencil cleaning is the foundation of effective SMT stencil care. A clean stencil ensures that solder paste is applied evenly and accurately. Here are proven methods and tips for keeping your stencil in top shape:

1. Clean After Every Print Cycle (When Necessary)

Depending on your production volume and the type of solder paste used, cleaning after every print cycle—or at least every few cycles—can prevent buildup. For high-volume runs, automated under-stencil wiping systems with specialized cleaning rolls can remove excess paste from the stencil's underside without interrupting production. These systems often use a combination of dry wipes and solvent-soaked wipes to ensure thorough cleaning.

For manual cleaning, use a lint-free cloth or stencil cleaning wipes soaked in a compatible solvent, such as isopropyl alcohol (IPA) with at least 90% purity, to avoid residue. Gently wipe the stencil surface to remove paste remnants.

2. Focus on Aperture Cleaning

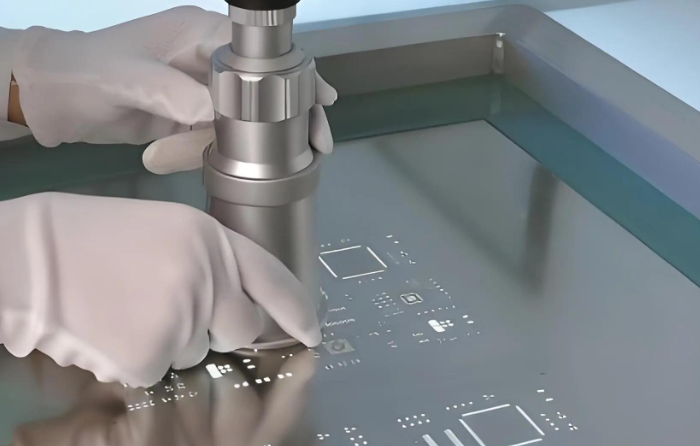

Aperture cleaning is critical because even small blockages can cause defects. Use a soft-bristled brush or compressed air to dislodge dried paste from the openings. For stubborn residue, ultrasonic cleaning machines can be highly effective. These devices use high-frequency sound waves in a cleaning solution to remove contaminants from even the smallest apertures without damaging the stencil. Ensure the cleaning solution is compatible with your stencil material to avoid corrosion.

Tip: For fine-pitch stencils with apertures smaller than 0.3 mm, extra care is needed during cleaning to prevent damage. Avoid excessive force when brushing or wiping.

3. Choose the Right Cleaning Solutions

Not all cleaning agents are suitable for SMT stencils. Avoid harsh chemicals that can corrode stainless steel or leave sticky residues. Opt for solvents specifically designed for stencil cleaning or high-purity IPA. Always test a small area of the stencil before applying a new cleaning solution to the entire surface.

4. Automate Cleaning for Consistency

For larger operations, investing in automated stencil cleaning equipment can save time and ensure consistent results. These machines often combine solvent application, wiping, and drying in a single process, reducing the risk of human error. They are especially useful for high-mix, low-volume production where stencils are changed frequently.

Essential Tips for SMT Stencil Maintenance

Beyond cleaning, proper maintenance practices help prolong the life of your stencil and maintain its performance during solder paste printing. Here are key strategies to follow:

1. Inspect Regularly for Damage

After each cleaning session, inspect the stencil under magnification for signs of wear, scratches, or bent edges. Even minor damage can affect paste release and lead to defects. If you notice issues, consider having the stencil repaired by a professional or replacing it if the damage is severe.

Tip: Keep a log of stencil usage and inspection results to track its condition over time. This data can help predict when a replacement might be needed.

2. Handle with Care

Always handle stencils with clean, gloved hands to avoid transferring oils or dirt onto the surface. Use designated tools or fixtures to move or mount the stencil, minimizing the risk of bending or scratching. Avoid stacking stencils directly on top of each other without protective layers, as this can cause surface damage.

3. Calibrate and Align Properly

During setup, ensure the stencil is correctly aligned with the PCB and printer. Misalignment can cause uneven pressure during printing, leading to inconsistent paste deposits and potential stencil wear. Regularly calibrate your printing equipment to maintain accuracy, checking parameters like squeegee pressure (typically between 3-5 kg for most setups) and print speed (around 20-40 mm/s for standard applications).

Storage Guidelines for SMT Stencils

How you store your SMT stencil when it's not in use is just as important as how you clean and maintain it. Poor storage practices can lead to contamination or physical damage. Follow these tips to protect your stencil:

1. Store in a Clean, Dry Environment

Keep stencils in a controlled environment with low humidity (below 50%) and stable temperatures (around 20-25°C) to prevent corrosion. Avoid areas prone to dust or chemical fumes, as these can settle on the stencil surface and affect performance.

2. Use Protective Covers or Cases

Store each stencil in a dedicated protective sleeve or case to shield it from scratches and contaminants. If you must stack multiple stencils, place a soft, non-abrasive separator between them to prevent direct contact.

3. Label and Organize

Clearly label each stencil with its part number or project name to avoid mix-ups. Organize them in a vertical rack or cabinet to minimize the risk of bending and make retrieval easier.

Optimizing Solder Paste Printing with Stencil Care

The ultimate goal of SMT stencil care is to achieve consistent, defect-free solder paste printing. By combining proper cleaning, maintenance, and storage, you can optimize the printing process. Here are additional best practices to tie it all together:

1. Use the Right Solder Paste and Stencil Thickness

Match the solder paste type and particle size to your stencil's aperture dimensions. For example, finer pitch components (below 0.5 mm) often require Type 4 or Type 5 solder paste with smaller particles for better release through tiny apertures. Stencil thickness also matters—common thicknesses range from 0.1 mm to 0.15 mm for most SMT applications. A mismatch can lead to over- or under-deposition of paste.

2. Monitor Print Parameters

Keep an eye on key printing parameters like squeegee angle (typically 45-60 degrees), pressure, and speed. Adjust these based on the stencil's condition and the specific PCB design to ensure even paste application. Regularly verify the results with a solder paste inspection (SPI) system to catch issues early.

3. Train Your Team

Ensure all operators are trained in proper stencil handling, cleaning, and printing techniques. A well-informed team can spot potential problems before they escalate, maintaining the stencil's performance over time.

Benefits of Proper SMT Stencil Care

Investing time and resources into SMT stencil care offers several tangible benefits for your PCB assembly process:

- Improved Print Quality: Clean, well-maintained stencils ensure precise solder paste deposits, reducing defects like bridging or insufficient solder.

- Cost Savings: Extending stencil life through proper care reduces replacement costs and minimizes material waste from misprints.

- Higher Throughput: Fewer printing errors mean less downtime for rework, boosting overall production efficiency.

- Consistency: Regular maintenance leads to repeatable results, critical for high-volume manufacturing.

Conclusion: Elevate Your SMT Process with Stencil Care

SMT stencil care is a vital component of successful solder paste printing and overall PCB assembly quality. By implementing regular stencil cleaning, focusing on aperture cleaning, following maintenance best practices, and storing stencils properly, you can achieve optimal printing results and extend the life of your tools. Whether you're running a small-scale operation or a high-volume production line, these strategies will help you minimize defects, save costs, and maintain consistency.

Start by evaluating your current stencil care routine and identifying areas for improvement. With the right approach, your SMT stencils will perform at their best, ensuring every print is a step toward a flawless final product. Stay committed to these practices, and watch your production quality soar.

ALLPCB

ALLPCB