One-stop PCB Assembly Services

ALLPCB one stop PCB Assembly Services

ALLPCB is one of top-speed PCB manufacturers in China, specializing in high quality and cheap PCB prototype & production, PCB assembly and SMT stencil services online, ALLPCB has professional experience in this field.

Since its launch, ALLPCB.com is committed to supplying the fast speed PCB manufacturing service for the makers, electronic engineers, and all electronic users. In order to help customers shorten product development time and build better market competitiveness.

ALLPCB offers one-stop and high-quality PCB prototype services, and affordable PCB assembly (PCBA) services that include PCB manufacture, components procurement and assembly all-in-one.

The service is ideal for engineering firms, makers, and students for applications including computers, telecommunications, automotive, digital, instrumentation, household appliances, electrical and mechanical equipment, and other high-tech electronic products.

What is PCB Assembly?

PCB(Printed circuit board) assembly is the process of connecting the electronic components with the wires on printed circuit boards to make PCB work. The traces or conductive pathways engraved in the laminated copper boards of PCBs are used within a non-conductive substrate in order to form the assembly.

Attaching the electronic components with the PCB is the concluding action before using fully operational electronic device.

Types of PCB Assembly

Printed circuit board assembly is advised to be done with carefulness, paying attention to details and absolute precision, as this would determine the successful operation of the electronic devices. The electronic machines can be ideally assembled with the PCBs in the following 3 ways:

l Surface Mount Assembly(SMT)

The technique that emerged in the 1960s, and further developed in the 1980s, is currently being widely used by many PCB assembly manufacturers and hobbyists. The process includes components with metal tabs that can be easily soldered to the PCBs. The technique offers higher circuit densities when the components are fixed at both sides of the PCBs with effective soldering methods.

Advantages:

1. SMT, which doesn’t require drilling, is less mechanically stressful than thru-hole assembly.

2. SMT is a faster and lower cost manufacturing process than through-hole assembly.

3. SMT is the optimal assembly method for component-rich designs and allows for more connections per component than thru-hole assembly.

Disadvantages:

1. SMT-assembled PCB prototypes and component repair can be more difficult than on a board assembled by through-hole soldering.

2. SMT components are often not as high-powered or high-voltage as thru-hole components.

l Plated through-hole technology (PTH):

This process applied for components with leads attached to them. PCBs used for this kind of assembly method always come with drilled holes.It is easy to assemble the PCBs with the components as the leads are effectively inserted into the drilled holes.

Advantages:

1. Thru-hole soldering provides stronger mechanical bonds than any other technique.

2. Thru-hole soldering is the optimal technique for connectors, transformers, electrolytic capacitors, and other heftier circuit board components.

3. Thru-hole soldering is considered to be the go-to process over SMT for many military or aerospace products.

Disadvantages:

1. Thru-hole soldering requires drilling into the bare board, which makes it a more time consuming process than SMT.

2. Thru-hole soldering is more expensive than using SMT.

3. Thru-hole mounting may not allow for as high a component density as SMT does.

4. Thru-hole mounting often requires hand-soldering, which is considered to be less reliable than the reflow ovens used in surface mount PCBA.

l Mixed technology (SMT and thru-hole soldering together)

Advantages:

1. Usually, this method is used for more complicated boards where some surface mounting combined with some drilling. This technology would be best suitable for a unique PCB layout.

Disadvantages;

1. Costs would be higher and lead time could be longer than normal assembly boards due to PTH components.

l Electro-mechanical assembly:

Electro-mechanical assembly, also known as box-build assembly, which uses elements like wire harnesses, custom metalwork, molded plastics, looms, and cable assembly, in order to assemble PCBs with electronic components. This method is not commonly used in PCB assembly manufacturing process.

Prototype PCB Assembly as Quick as 24 Hour

Our printed circuit board assembly service is North America's leading one-stop solution for PCB and assembly under one roof; specializing in small and medium runs with fast lead-times and no minimum quantity requirements.

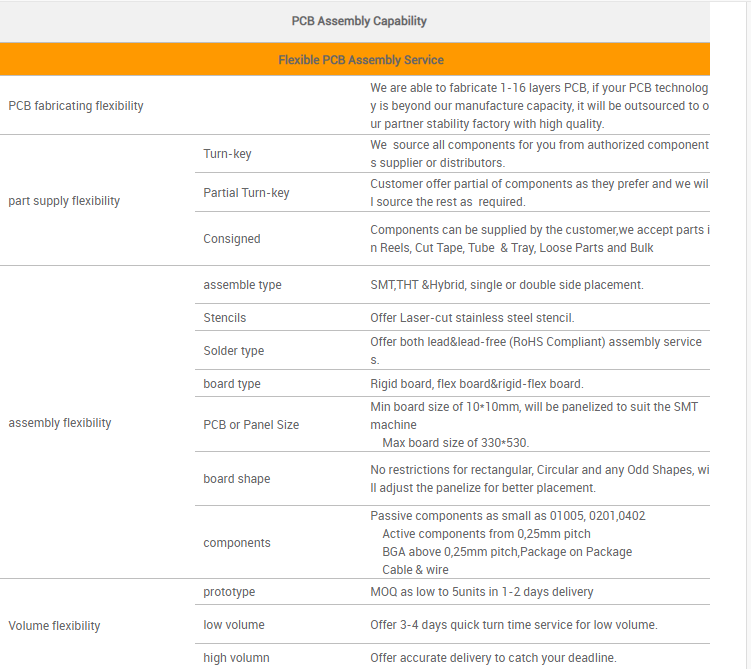

Advanced Capabilities

To learn more, click here

Why ALLPCB?

l Topspeed PCB&PCBA Prototype Manufacturer

l Professional Engineering Services

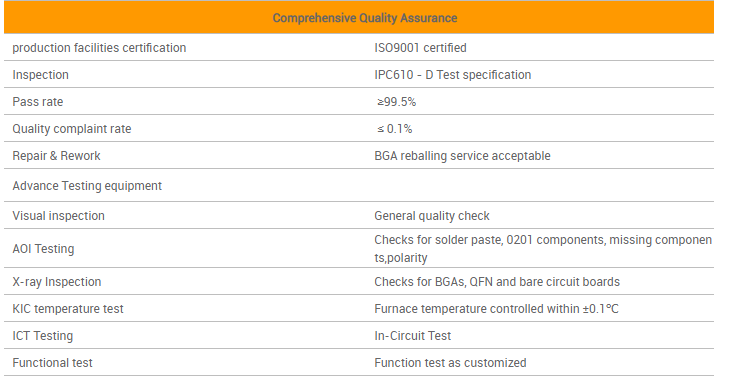

l Reliable Quality

l Transparent Pricing

l On-time Shipping

l Dedicated Customer Services

How to get a quote for PCBA Services?

1. Assembly online quote: This is also an instant quote. You can get the labour assembly cost in seconds. Click ALLPCB Assembly Quote to get a quote now. Sales persons are 24 hours online, you can send eamil to: service@allpcb.com

2. BOM pricing: Send your BOM (Bill of Materials) to service@allpcb.com , we will email you the BOM price in 24 hours. BOM must include the quantities, reference designators, and manufacturer name and manufacturer part number. (If you supply components yourself, just send to ALLPCB and leave out this step.)

3. Place order: If you already have your quote, then you are ready to place your order at your convenience!

New Customer Special Offer

Newly register customers can get $10 credit which can be directly deducted in order!

Register at https://www.allpcb.com/ to get!