What’s the impact of the soldermask thickness?

In order to ensure the quality of PCB boards, it is necessary to choose the right solder mask and control the screen printing technology. In terms of electrical properties, the soldermask thickness will have a very large impact on the impedance, the safety and the feasibility of PCB assembly, so the soldermask thickness should be very strictly controlled.

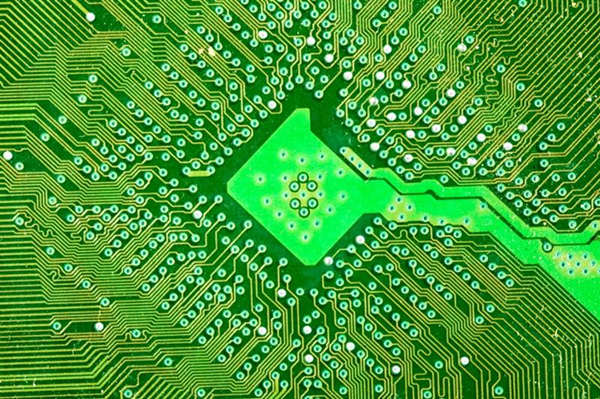

Soldermask Thickness

If the soldermask is too thin, the copper will be exposed, which can cause SMT problems. According to IPC standards, the corner lines are usually greater than 8 microns. Otherwise, it will be yellow while baking, and will result in leaking copper.

If the soldermask is too thick, the parts may appear tilt, and it will affect the quality of welding, result in IC Weld and other issues. Heavy copper always have thick solder resist.

Once we use a squeegee blade to scrape the solder mask on the surface of the copper but it is not very easy to scrape. In addition, a good solder mask cannot be easily worn because of its great adhesion strength. Only when someone in the production line scrape the solder resist with sharp metal blade deliberately, otherwise, even if the thickness is slightly thinner, the copper will be also not seriously exposed. What the most important is that whether the solder mask adhesion strength is enough or not.

Therefore, most customers will just limit the upper limit of the ink. The lower limit will not be so strictly controlled, as long as the copper will not be exposed (including pseudo exposed copper) according to the visual inspection standard.

If you want to inspect the soldermask thickness, you can take some slices of printed circuit board to measure the solder resist thickness at different locations on the circuit.