If you’re wondering whether 1.6mm is the only standard PCB thickness to consider for your project, the answer is no. While 1.6mm is widely regarded as the industry standard due to its balance of durability and versatility, there are several other PCB thickness options available, such as 0.8mm, 1.0mm, 1.2mm, and 2.0mm, each suited for specific applications. In this comprehensive guide, we’ll dive into the world of standard PCB thickness, compare 1.6mm PCBs with other options, and explore how different thicknesses impact design and performance across various industries.

Why PCB Thickness Matters in Design and Manufacturing

Printed Circuit Board (PCB) thickness plays a critical role in the performance, durability, and functionality of electronic devices. The thickness of a PCB affects its mechanical strength, PCB thermal management, electrical performance, and even manufacturing costs. Choosing the right PCB thickness ensures that your board can withstand environmental stresses, support the components mounted on it, and maintain signal integrity for high-speed applications.

Standard PCB thickness options are often determined by industry norms, material availability, and the specific needs of an application. While 1.6mm is the most common thickness, understanding the full range of PCB thickness options can help engineers and designers make informed decisions for their projects.

What Is the Standard PCB Thickness?

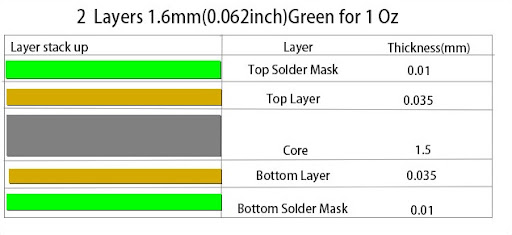

The term "standard PCB thickness" often refers to 1.6mm (or approximately 0.062 inches), a value that has become a benchmark in the industry. This thickness originated from the early days of PCB manufacturing when it was found to provide a good balance between rigidity and flexibility, making it suitable for a wide range of applications. It also aligns with standard manufacturing processes and equipment, reducing costs for both producers and customers.

However, standard PCB thickness isn’t limited to just 1.6mm. Other common thicknesses include:

- 0.4mm to 0.6mm: Ultra-thin boards used in compact or flexible designs.

- 0.8mm: Often used in communication devices where lightweight and slim profiles are critical.

- 1.0mm: Common in consumer electronics like smartphones and tablets for space-saving designs.

- 1.2mm: A slightly thinner alternative to 1.6mm, used in portable devices.

- 1.6mm: The industry standard for general-purpose applications.

- 2.0mm and above: Thicker boards for high-power or industrial applications requiring extra durability.

Each of these PCB thickness options serves a unique purpose depending on the design requirements, which we’ll explore in detail below.

1.6mm PCB: The Industry Standard

A 1.6mm PCB is often the default choice for many engineers due to its versatility. This thickness offers a robust structure that can support multiple layers (typically 2 to 6 layers for most designs) and handle moderate mechanical stress. It’s widely used in applications like computer motherboards, industrial control systems, and general-purpose electronics.

Key benefits of a 1.6mm PCB include:

- Mechanical Stability: It provides enough rigidity to prevent bending or warping under normal conditions.

- Thermal Performance: The thickness allows for better heat dissipation compared to thinner boards, which is essential for components that generate significant heat.

- Signal Integrity: For high-speed designs, a 1.6mm PCB with proper layer stacking can maintain impedance control, often around 50 ohms for single-ended signals or 100 ohms for differential pairs.

- Cost-Effectiveness: As the most common thickness, manufacturing a 1.6mm PCB is often more economical due to standardized processes.

However, 1.6mm isn’t always the best choice. For instance, in compact devices where space is limited, a thinner PCB might be more appropriate. Similarly, for high-power applications, a thicker board could be necessary to handle increased current loads.

PCB Thickness Options: A Detailed Comparison

Let’s break down the most common PCB thickness options and compare them to the 1.6mm standard to understand their unique advantages and limitations.

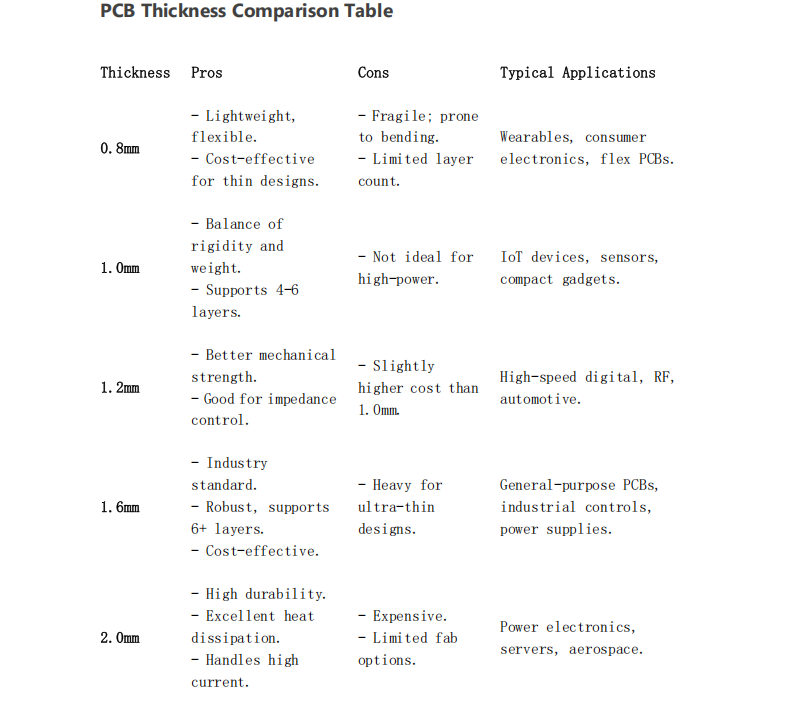

0.8mm PCB: Lightweight and Compact

A 0.8mm PCB is half the thickness of the standard 1.6mm board, making it ideal for applications where weight and space are critical factors. These boards are often used in communication devices like wireless modules and IoT gadgets.

- Advantages: Reduced weight and slimmer profile, suitable for handheld or wearable devices.

- Limitations: Lower mechanical strength, making it prone to bending or cracking under stress. Limited layer count (often 1-2 layers) and reduced heat dissipation.

- Applications: Bluetooth modules, smartwatches, and compact sensors.

1.0mm PCB: A Middle Ground for Consumer Electronics

At 1.0mm, this thickness strikes a balance between the ultra-thin 0.8mm and the standard 1.6mm. It’s commonly used in consumer electronics where moderate durability and a slim design are needed.

- Advantages: Slightly better mechanical strength than 0.8mm while still maintaining a compact form factor.

- Limitations: Still not as robust as 1.6mm, limiting its use in high-stress environments.

- Applications: Smartphones, tablets, and small audio devices.

1.2mm PCB: A Thinner Alternative to 1.6mm

A 1.2mm PCB is often chosen as a compromise between the standard 1.6mm and thinner options like 1.0mm. It offers a good mix of durability and space efficiency.

- Advantages: Lighter and thinner than 1.6mm, yet stronger than 1.0mm or 0.8mm boards. Suitable for designs with up to 4 layers.

- Limitations: Reduced thermal capacity compared to 1.6mm, which can be an issue for heat-intensive applications.

- Applications: Portable electronics, GPS devices, and compact power supplies.

2.0mm and Above: Heavy-Duty Solutions

Thicker PCBs, such as 2.0mm or even 2.4mm, are designed for applications requiring high durability and current-carrying capacity. These boards are often used in industrial and automotive sectors.

- Advantages: Exceptional mechanical strength to withstand vibration and shock. Higher thermal mass for better heat dissipation and support for heavy copper layers (e.g., 2 oz or more) for high-current designs.

- Limitations: Increased weight and cost. Not suitable for compact or lightweight devices.

- Applications: Power inverters, automotive control units, and industrial machinery.

PCB Thickness Applications: Choosing the Right Fit

Understanding PCB thickness applications is key to selecting the appropriate board for your project. Here’s how different industries and use cases align with specific thicknesses:

Consumer Electronics

In consumer electronics, space and weight are often the primary concerns. Devices like smartphones, wearables, and earbuds typically use thinner PCBs (0.8mm to 1.2mm) to fit into small enclosures. These boards prioritize compactness over heavy-duty performance, though they must still handle moderate power and signal requirements. For example, a typical smartphone PCB might use a 1.0mm thickness to balance durability with a slim design.

Industrial and Automotive

Industrial and automotive applications demand robustness due to harsh operating conditions like vibration, temperature extremes, and mechanical stress. Thicker PCBs (1.6mm to 2.4mm) are often chosen for their ability to support heavy components and resist environmental challenges. For instance, an automotive control unit might use a 2.0mm PCB to ensure reliability in high-vibration environments.

High-Speed and RF Designs

For high-speed digital or radio frequency (RF) designs, PCB thickness impacts signal integrity and impedance control. A 1.6mm PCB is often ideal as it allows for controlled impedance stacks, typically maintaining 50-ohm traces for single-ended signals. Thinner boards like 0.8mm may struggle with consistent impedance due to reduced dielectric spacing, while thicker boards can introduce unwanted signal delays in some designs.

Power Electronics

In power electronics, such as inverters or chargers, heat dissipation and current capacity are critical. Thicker PCBs (2.0mm or more) with heavy copper layers (e.g., 2 oz or 3 oz) are preferred to handle high currents—often exceeding 10 amps—and manage thermal loads effectively. These boards ensure long-term reliability under demanding conditions.

Factors to Consider When Choosing PCB Thickness

Selecting the right PCB thickness involves more than just picking a standard value. Here are some key factors to keep in mind:

- Component Weight and Size: Heavier components require thicker boards for support. For example, large transformers or connectors might necessitate a 2.0mm PCB to prevent board flexing.

- Layer Count: Multilayer designs often need thicker boards to accommodate additional dielectric layers. A 6-layer board, for instance, is commonly built on a 1.6mm thickness for stability.

- Thermal Management: Heat-generating components require thicker boards or additional copper to dissipate heat. A 1.6mm or 2.0mm PCB can handle higher thermal loads compared to a 0.8mm board.

- Space Constraints: Compact designs prioritize thinner boards to save space, even if it means sacrificing some durability.

- Cost: Non-standard thicknesses (e.g., 0.6mm or 2.4mm) may increase manufacturing costs due to specialized processes or materials.

Suggested Reading: The Ultimate Guide to Standard PCB Thickness: Choosing the Right Fit for Your Project

Conclusion: Beyond 1.6mm—Finding the Right PCB Thickness for Your Needs

While a 1.6mm PCB remains the go-to choice for many applications due to its balance of strength, cost, and versatility, it’s far from the only option. From ultra-thin 0.8mm boards for compact gadgets to robust 2.0mm boards for industrial power systems, the range of standard PCB thickness options allows engineers to tailor their designs to specific requirements. By considering factors like mechanical stress, thermal needs, signal performance, and space constraints, you can select the ideal thickness for your project.

Understanding PCB thickness applications and making informed comparisons ensures that your design performs reliably while meeting cost and manufacturing goals. Whether you stick with the tried-and-true 1.6mm or explore other PCB thickness options, the key is to align your choice with the unique demands of your application.

ALLPCB

ALLPCB