Castellated holes, also known as plated half-holes, are a vital feature in modern printed circuit board (PCB) design. These specialized structures allow engineers to connect PCBs directly to one another, simplifying assembly and enabling compact, modular systems. Whether you're designing for IoT devices, wireless modules, or breakout boards, understanding castellated holes and PCB castellation can significantly enhance your projects. In this blog, we'll dive into what castellated holes are, their advantages, applications, design considerations, and manufacturing challenges—offering practical insights to help you succeed.

This guide is tailored for engineers seeking actionable information. We'll explore the technical details of PCB castellation, provide specific examples, and share design tips to optimize your work. Let's get started.

What Are Castellated Holes?

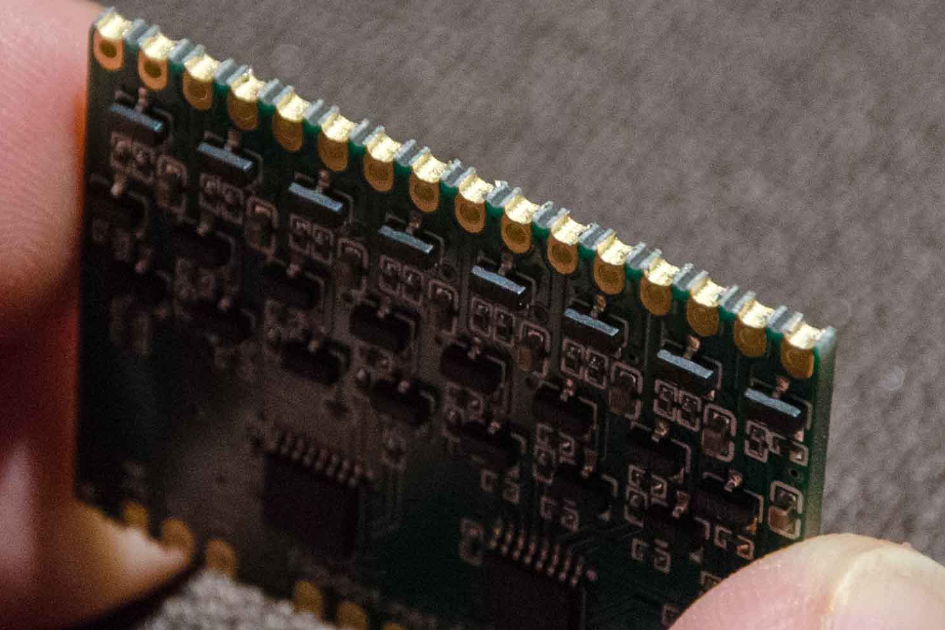

Castellated holes are half-circular, plated indentations located along the edges of a PCB. Unlike standard vias or plated-through holes (PTH), which connect layers within a board, castellated holes are designed for board-to-board connections. They are typically drilled as full holes during fabrication and then milled in half, leaving a plated semi-circle exposed on the board's edge. This plating, often copper or gold, ensures a reliable electrical and mechanical connection when soldered to another PCB or component.

The name 'castellated' draws from their resemblance to the notched patterns on castle walls. Over the years, advancements in PCB manufacturing have refined this feature, making it more precise and adaptable to complex designs. Today, castellated holes are a cornerstone of surface-mount technology (SMT), enabling seamless integration in space-constrained applications.

Advantages of Castellated Holes

Castellated holes bring several benefits to PCB design, making them a go-to solution for engineers. Here's why they stand out:

- Improved Connectivity: The plated edges provide a strong electrical link between boards, reducing signal loss. This is critical in high-frequency applications, such as RF modules operating at 2.4 GHz, where maintaining signal integrity is non-negotiable.

- Enhanced Durability: Unlike traditional connectors that wear out over time, castellated holes withstand repeated connections and disconnections. This durability suits modular systems like IoT devices, which may need hardware swaps during development or upgrades.

- Simplified Assembly: By eliminating the need for separate connectors, castellated holes streamline the soldering process. This reduces assembly time and cuts costs—key advantages for high-volume production runs.

- Space Efficiency: Without bulky connectors, designs become more compact. For example, a wearable device with a footprint of just 20mm x 20mm can use castellated holes to stack a sensor board directly onto a processor board, saving valuable space.

These advantages make PCB castellation a versatile choice for modern electronics, balancing performance and practicality.

Applications of Castellated Holes

Castellated holes are used across a wide range of industries and products. Here are some common applications:

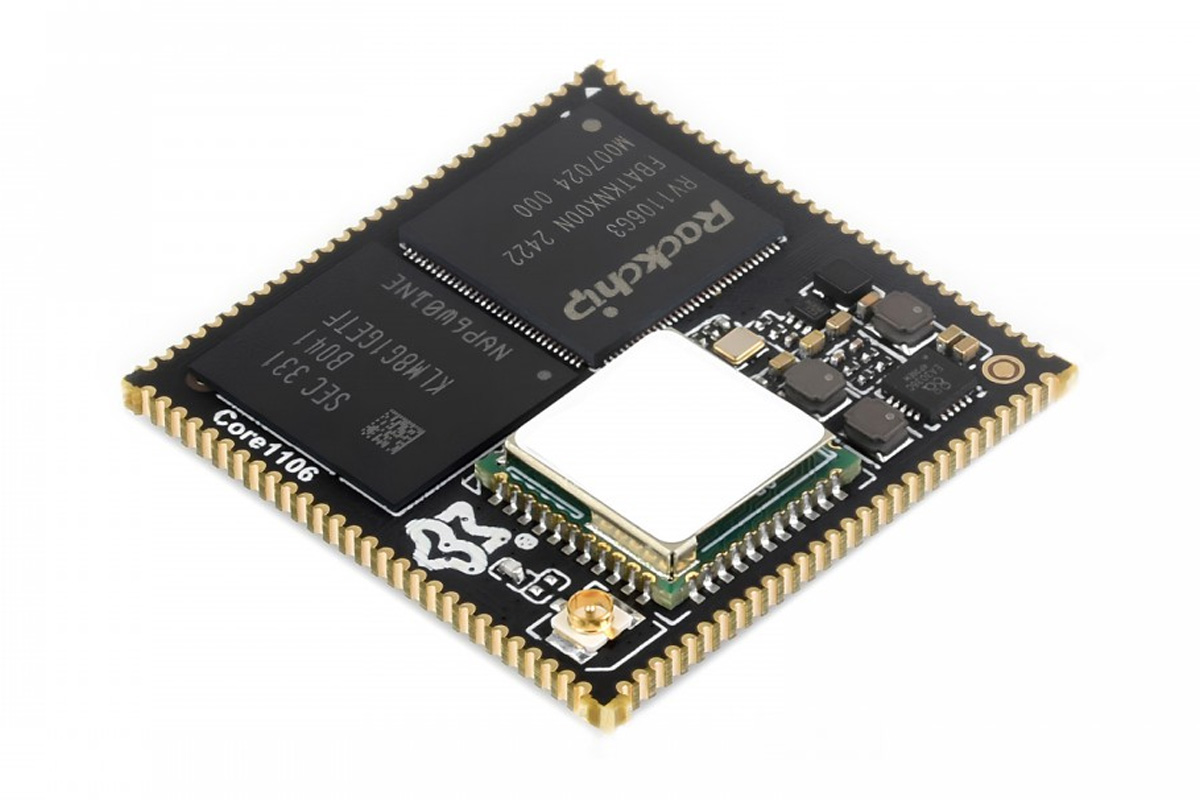

- Wireless Communication Modules: Devices like Wi-Fi, Bluetooth, and RF modules rely on castellated holes for easy integration. For instance, a Bluetooth Low Energy (BLE) module might use them to connect to a mainboard, ensuring a reliable link at 2.4 GHz.

- Breakout Boards: These boards, popular in prototyping, use castellated holes to mount onto larger systems. A microcontroller breakout board, for example, can be soldered directly to a development board for testing.

- IoT Devices: The modular nature of IoT systems—think smart sensors or connected wearables—makes castellated holes ideal for linking components like processors, antennas, and power modules.

- Consumer Electronics: Compact gadgets, such as fitness trackers or smartwatches, leverage castellated holes to maintain small form factors while ensuring robust connections.

Beyond these, castellated holes enable wireless PCB-to-PCB links, simplifying designs where cables or connectors are impractical. Their versatility makes them a staple in innovative engineering.

Design Considerations for Castellated Holes

Incorporating castellated holes into your PCB requires careful planning. Here are the key factors to consider:

- Hole Size and Spacing: The minimum diameter for castellated holes is typically 0.5mm, with a spacing of at least 0.5mm between holes. Smaller sizes (e.g., 0.3mm) are possible but demand advanced fabrication tools, increasing costs.

- Surface Finish: Electroless Nickel Immersion Gold (ENIG) is a popular choice due to its corrosion resistance and solderability. For high-reliability applications, a gold thickness of 0.05–0.1µm over 3–6µm of nickel ensures long-term performance.

- Pad Design: Larger pads improve solder joint strength. Aim for an annular ring (the plated area around the hole) of at least 0.25mm on both the top and bottom layers. For a 0.5mm hole, a 1mm pad diameter is a solid starting point.

- Placement: Keep castellated holes away from components and traces to avoid interference during soldering. A clearance of 0.5mm from nearby features is a safe minimum.

- Board Thickness: Thicker boards (e.g., 1mm or 1.6mm) better support castellated holes, preventing cracking during milling or assembly. Thinner boards (below 0.8mm) may require extra reinforcement.

By addressing these elements, you can optimize your design for both functionality and manufacturability.

Manufacturing Challenges and Solutions

Producing castellated holes isn't without hurdles. Here's a look at the common challenges and how they're tackled:

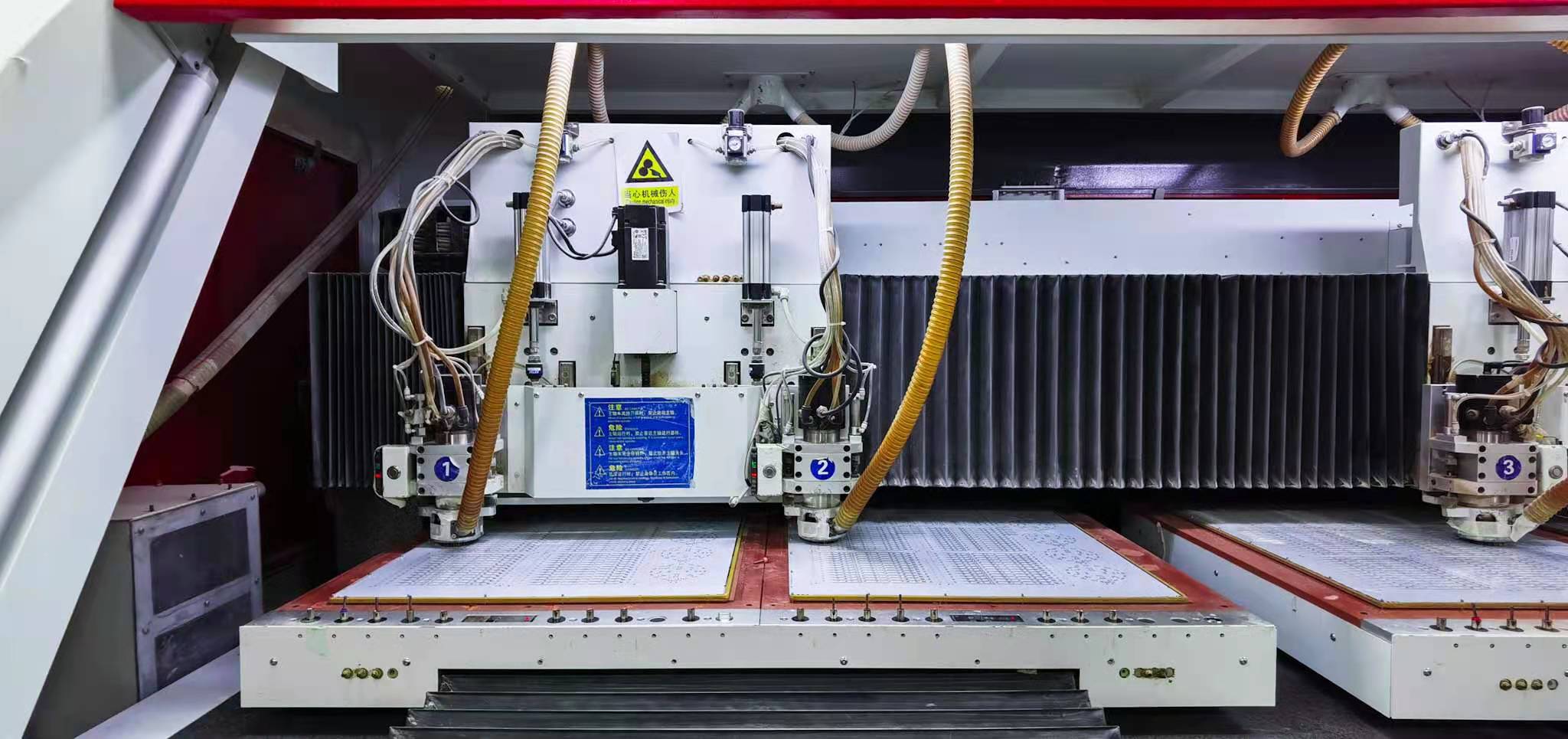

- Copper Burrs: Milling the half-holes can leave copper burrs inside, risking weak solder joints or shorts. Advanced CNC milling with speeds up to 50,000 RPM and post-process deburring can eliminate this issue.

- Plating Integrity: The plating must remain intact after milling. Poor plating—say, less than 25µm of copper—can lead to connection failures. Manufacturers counter this with precise electroplating and quality checks, ensuring thickness meets IPC Class 3 standards (25–35µm).

- Alignment Precision: Misaligned holes disrupt board-to-board soldering. Tolerances as tight as ±0.05mm are achievable with modern laser-guided milling machines, ensuring perfect fitment.

These challenges highlight the need for skilled manufacturing partners. With the right techniques, castellated holes can meet even the strictest requirements.

How ALLPCB Supports Engineers with Castellated Holes

At ALLPCB, we're equipped to help engineers bring castellated hole designs to life. Our advanced manufacturing capabilities—like high-precision CNC milling and robust plating processes—deliver PCBs that meet exacting standards. Need to test a concept quickly? Our quick-turn prototyping gets you from design to prototype in as little as 24 hours. Plus, with our global logistics network, your boards arrive on time, anywhere in the world. Whether it's a small IoT module or a large production run, we're here to make your project a success with cost-effective, reliable solutions.

Conclusion

Castellated holes and PCB castellation are game-changers for engineers, offering a blend of connectivity, durability, and simplicity. From wireless modules to IoT systems, their applications are vast, and their benefits are clear. By mastering the design considerations—hole size, pad layout, and more—you can unlock their full potential. Yes, manufacturing challenges exist, but with the right expertise, they're easily overcome.

We hope this guide has given you the insights needed to integrate castellated holes into your next project. At ALLPCB, we're ready to support you with the tools and services to turn your ideas into reality. Ready to get started? Let's build something great together.

ALLPCB

ALLPCB