In today’s tech-driven world, consumer electronics are everywhere—smartphones in our pockets, smart appliances in our homes, and wearable devices on our wrists. But behind every beep, buzz, and notification is an unseen hero: the Printed Circuit Board (PCB). These small, intricate boards are the backbone of modern electronics, making our daily lives smoother and more connected. So, how do consumer electronics PCBs power our routines? They provide the essential framework for devices to function, connecting components and ensuring seamless operation in everything from smartphones to home appliances.

In this blog, we’ll dive deep into the world of consumer electronics PCB applications, exploring their vital role in smartphones, home appliances, and wearable devices. Whether you’re an engineer, a tech enthusiast, or just curious about the technology around you, this guide will uncover how PCBs shape the tools we rely on every day.

What Are Consumer Electronics PCBs and Why Do They Matter?

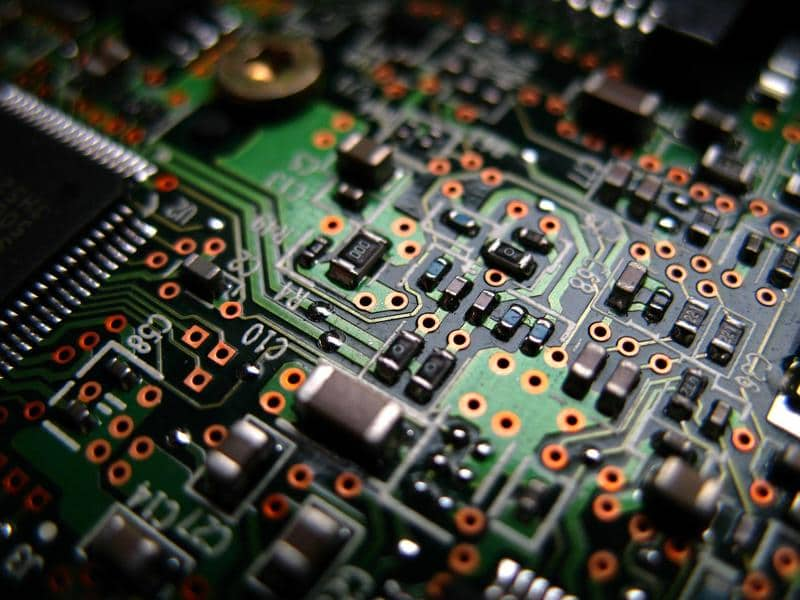

At its core, a PCB is a flat board made of insulating material, like fiberglass, with conductive pathways etched onto it. These pathways connect electronic components such as resistors, capacitors, and microchips, allowing them to communicate and work together. In consumer electronics, PCBs are tailored to fit specific devices, balancing size, performance, and durability.

PCBs matter because they enable the functionality of nearly every electronic device we use. Without them, your smartphone wouldn’t process calls, your microwave wouldn’t heat food, and your fitness tracker wouldn’t count steps. Their design directly impacts a device’s speed, efficiency, and reliability. For instance, a well-designed PCB can handle high-frequency signals in smartphones, often operating at speeds up to 2.4 GHz for Wi-Fi connectivity, ensuring lag-free performance.

Consumer Electronics PCB Applications: A Broad Impact

The scope of consumer electronics PCB applications is vast, touching almost every aspect of modern life. From communication to entertainment, these boards are the silent enablers of technology. Let’s explore some of the most common areas where PCBs make a difference, focusing on smartphones, home appliances, and wearable devices.

PCB in Smartphones: The Heart of Connectivity

Smartphones are perhaps the most ubiquitous consumer electronic devices, and their PCBs are engineering marvels. These boards are incredibly compact, often smaller than a credit card, yet they pack in layers of circuitry to manage everything from calls to apps. A typical smartphone PCB might include up to 8-12 layers, each handling specific functions like power distribution, signal processing, and data storage.

One critical aspect of PCBs in smartphones is their ability to manage high-speed signals. For example, 5G-enabled devices rely on PCBs with low dielectric loss materials to support frequencies up to 6 GHz, ensuring fast data transfer rates. Additionally, thermal management is crucial, as smartphones generate heat during intensive tasks like gaming or video streaming. PCBs with integrated heat dissipation layers help maintain safe operating temperatures, often below 40°C under heavy load.

Beyond performance, smartphone PCBs are designed for miniaturization. Advanced manufacturing techniques allow components to be placed just 0.4 mm apart, maximizing space efficiency. This is why modern phones can fit powerful processors, multiple cameras, and long-lasting batteries into such slim designs.

PCB in Home Appliances: Making Life Easier

Home appliances have evolved from simple mechanical devices to smart, connected systems, and PCBs are at the center of this transformation. From refrigerators to washing machines, PCBs control operations, monitor performance, and even connect devices to the internet for remote access.

Take a modern refrigerator as an example. Its PCB manages temperature sensors, adjusts compressor activity, and displays information on a digital panel. These boards often operate at low frequencies, around 50-60 Hz, to match household power standards, ensuring energy efficiency. A typical refrigerator PCB might regulate power consumption to keep it under 150 watts during normal operation, saving energy and reducing costs.

In smart home appliances, PCBs also enable connectivity features. A washing machine with Wi-Fi capability uses a PCB to communicate with your smartphone, allowing you to start or monitor cycles remotely. These boards must be durable, often designed to withstand humidity levels up to 85% and temperature fluctuations from 0°C to 60°C, ensuring reliability in challenging environments like kitchens or laundry rooms.

PCB in Wearable Devices: Technology on the Move

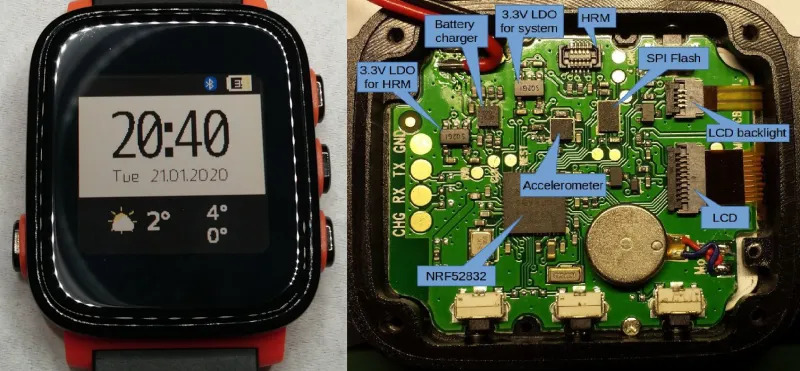

Wearable devices, such as fitness trackers and smartwatches, represent one of the fastest-growing segments of consumer electronics. The PCBs in these devices face unique challenges: they must be small, flexible, and energy-efficient while delivering robust performance.

A fitness tracker’s PCB, for instance, might measure just 20 mm by 30 mm, yet it handles heart rate sensors, motion detectors, and Bluetooth connectivity. These boards often use flexible or rigid-flex materials to conform to the curved shapes of wearables, ensuring comfort for the user. Power efficiency is critical, with many wearable PCBs designed to operate on currents as low as 7 microamps during sleep mode, extending battery life to several days.

Signal integrity is another key concern in wearable devices. With components packed so closely together, PCBs must minimize electromagnetic interference (EMI) to ensure accurate data from sensors. This often involves precise impedance control, targeting values around 50 ohms for high-frequency signals like Bluetooth at 2.4 GHz.

Key Challenges in Designing PCBs for Consumer Electronics

Designing PCBs for consumer electronics isn’t just about functionality; it’s about overcoming specific challenges to meet user demands for smaller, faster, and more reliable devices. Here are some of the biggest hurdles engineers face:

- Miniaturization: As devices shrink, so must their PCBs. This requires high-density interconnect (HDI) designs, where vias (connections between layers) are as small as 0.1 mm in diameter, allowing more components in less space.

- Thermal Management: Electronics generate heat, and poor dissipation can lead to failure. PCBs often incorporate copper layers with thermal conductivity up to 400 W/m·K to manage temperatures effectively.

- Signal Integrity: High-speed devices need PCBs that prevent signal loss or interference. This means controlling impedance (often targeting 50-100 ohms) and using materials with low dielectric constants, around 3.5 or less, for better performance.

- Durability: Consumer electronics face drops, moisture, and wear. PCBs must be built to last, often using protective coatings that resist corrosion at humidity levels up to 90%.

Addressing these challenges ensures that the devices we rely on daily perform consistently, whether it’s a smartphone surviving a busy day or a wearable tracking a long workout.

How PCBs Shape the Future of Consumer Electronics

The role of PCBs in consumer electronics isn’t static; it’s evolving with emerging technologies. As we move toward smarter, more connected lives, PCBs are adapting to support innovations like the Internet of Things (IoT), artificial intelligence (AI), and 5G networks.

In IoT, PCBs enable devices to communicate seamlessly, from smart thermostats to connected doorbells. These boards often integrate low-power wireless modules, operating at currents below 10 mA, to conserve energy in always-on systems. For AI-driven devices, PCBs must handle complex processing tasks, supporting clock speeds above 2 GHz in compact layouts.

5G technology, with its ultra-fast data rates, demands PCBs with advanced materials that maintain signal integrity at frequencies up to 28 GHz. This push for higher performance also drives the use of sustainable materials in PCB manufacturing, reducing environmental impact while meeting consumer needs.

Why Quality Matters in Consumer Electronics PCBs

Not all PCBs are created equal. The quality of a PCB directly affects a device’s performance, lifespan, and safety. A poorly designed board can lead to signal delays, overheating, or even complete failure. For instance, a smartphone PCB with mismatched impedance might drop calls or slow down data speeds, frustrating users.

High-quality PCBs, on the other hand, ensure reliability. They’re tested for electrical performance, often meeting standards like IPC-6012 for rigidity and durability. They also undergo thermal cycling tests, enduring temperature swings from -40°C to 85°C, to guarantee they won’t crack under stress. For engineers and manufacturers, investing in top-tier PCB design and production translates to fewer returns and happier customers.

Conclusion: Celebrating the Silent Power of PCBs

Printed Circuit Boards may be hidden inside our devices, but their impact on our daily lives is undeniable. From the intricate designs powering smartphones to the robust boards in home appliances and the compact circuits in wearable devices, consumer electronics PCB applications touch every corner of modern life. They ensure our gadgets work seamlessly, connecting us to information, entertainment, and each other.

As technology advances, the role of PCBs will only grow, driving innovations that make our lives even more efficient and connected. So, the next time you pick up your phone, adjust your smart thermostat, or check your fitness tracker, remember the unseen hero—the PCB—making it all possible.

ALLPCB

ALLPCB