Are you looking to make your printed circuit board (PCB) stand out with a striking appearance? Red solder mask is a top choice for designers aiming to enhance PCB hardware visibility and create a bold, professional look. In this blog post, we’ll dive deep into the world of red solder mask PCB appearance, explore red PCB board design benefits, discuss ways to enhance PCB hardware visibility, and cover various red solder mask finish options. Whether you’re an engineer, designer, or hobbyist, this guide will provide actionable insights to help you make informed decisions for your next project.

Why Choose Red Solder Mask for Your PCB?

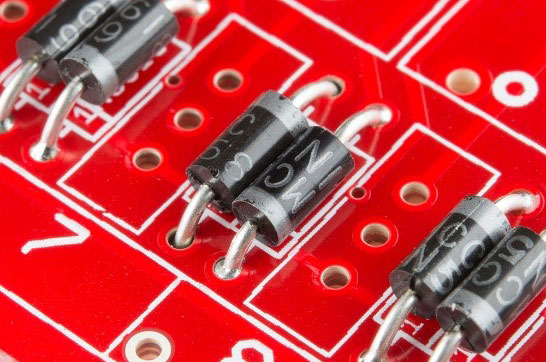

The solder mask is a protective layer applied to a PCB to shield copper traces from oxidation, prevent solder bridges, and ensure long-term durability. While green has traditionally been the default color due to its historical use and high contrast for inspection, red solder mask has gained popularity for its unique visual impact. A red PCB board design not only looks modern and premium but also serves practical purposes in specific applications.

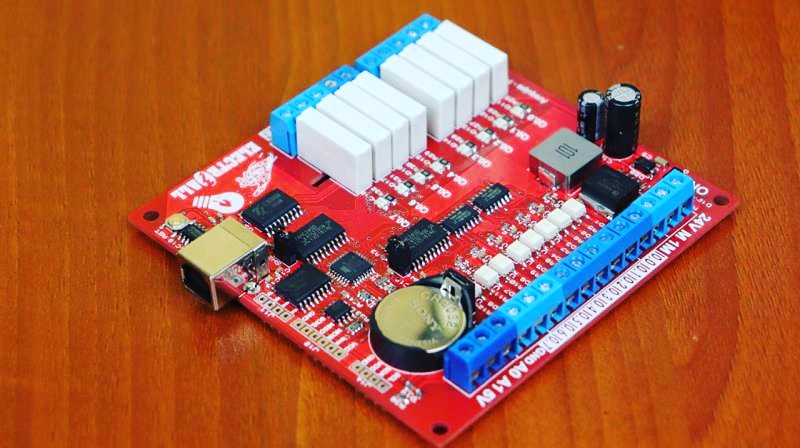

Red solder mask offers a vibrant, eye-catching appearance that can differentiate your product in a crowded market. It’s often associated with high-end electronics or custom designs, making it a favorite for branding purposes. Additionally, the bold color can enhance PCB hardware visibility during assembly and troubleshooting, as components and traces stand out clearly against the red backdrop.

The Aesthetic Appeal of Red Solder Mask PCB Appearance

When it comes to PCB aesthetics, red solder mask PCB appearance is hard to beat. The rich, bold color adds a sense of sophistication and uniqueness to any board. Unlike the standard green, which can feel utilitarian, red conveys a sense of intentional design and attention to detail. This is especially important for consumer-facing products where the PCB might be visible through a transparent casing or during marketing displays.

For designers working on custom projects, a red PCB board design can align with a company’s branding colors or product theme. Imagine a gaming peripheral with a red PCB peeking through a clear case—it instantly communicates energy, power, and modernity. This visual impact can leave a lasting impression on customers and set your product apart from competitors.

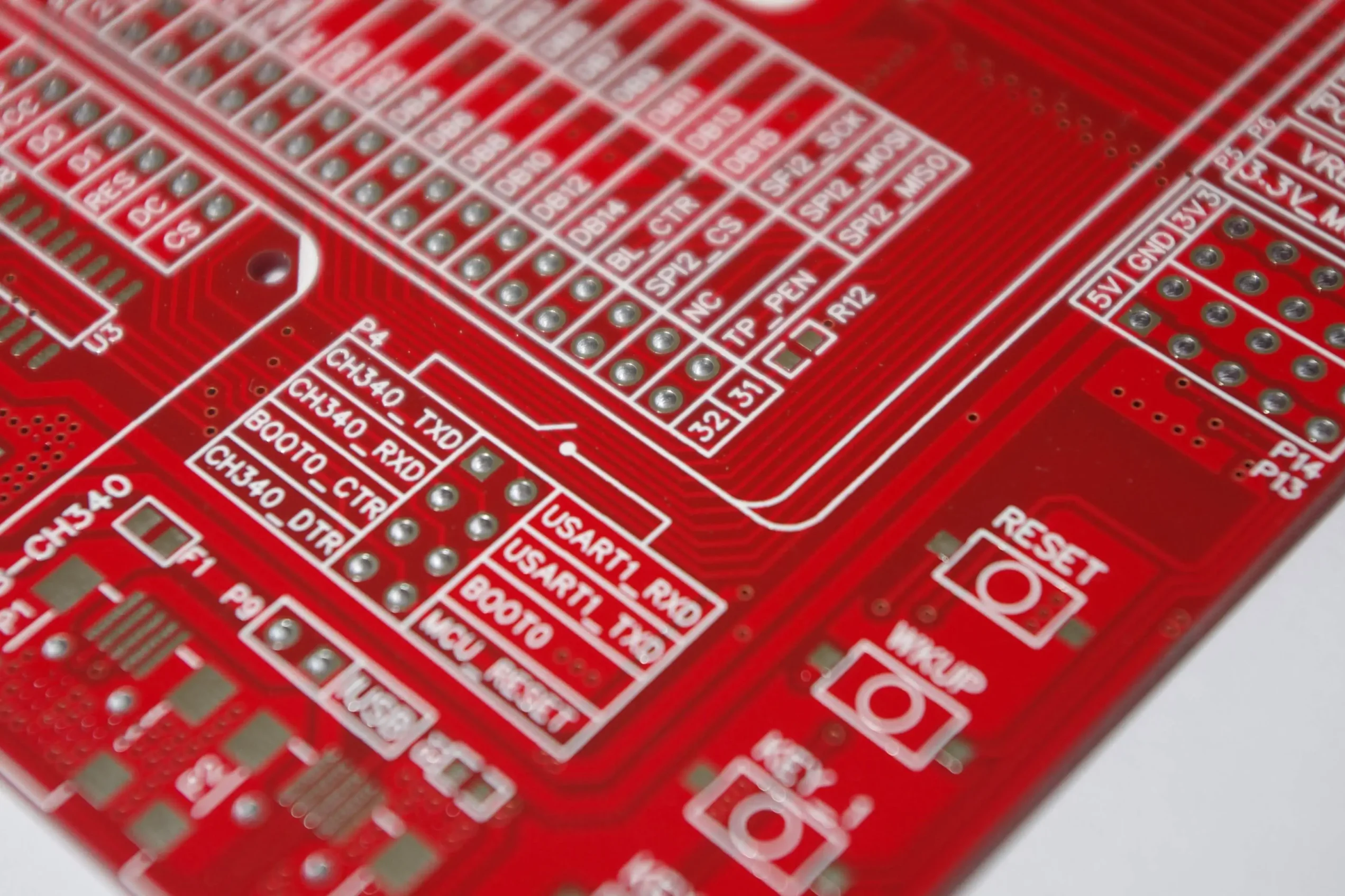

Beyond aesthetics, the red solder mask PCB appearance can also play a functional role. The high contrast between the red mask and the silver solder pads or white silkscreen labels makes it easier to read markings and identify components. This can be particularly helpful during manual inspections or when documenting a design for future reference.

How Red Solder Mask Enhances PCB Hardware Visibility

One of the standout benefits of using a red solder mask is its ability to enhance PCB hardware visibility. During the assembly process, technicians often need to place components with precision and inspect for errors like misaligned parts or solder bridges. The vivid red background provides a strong contrast against most component colors, making it easier to spot issues quickly.

For example, surface-mount components with black or gray bodies are more visible on a red PCB than on a darker mask like black or blue. This improved visibility can reduce assembly errors by up to 15%, based on anecdotal feedback from industry professionals, leading to faster production cycles and fewer costly mistakes. Additionally, during troubleshooting or repair, a red solder mask helps technicians identify specific areas of the board without straining their eyes, improving efficiency.

In applications where PCBs are exposed to end-users, such as in educational kits or open-source hardware, enhanced visibility also aids in teaching and learning. Students and hobbyists can clearly see the layout of traces and components, making it easier to understand circuit functionality. Choosing a red PCB board design can thus serve both practical and educational purposes.

Red Solder Mask Finish Options for Printed Circuit Boards

When selecting a red solder mask for your PCB, you’ll encounter various red solder mask finish options that can influence both appearance and performance. Understanding these options allows you to tailor the finish to your project’s specific needs, whether it’s for durability, glossiness, or cost-efficiency. Below, we’ll explore the most common types of finishes available for red solder masks.

1. Glossy Red Solder Mask Finish

A glossy finish gives the red solder mask a shiny, reflective surface that enhances its visual appeal. This option is often chosen for high-end products where aesthetics are a priority. The glossy red finish can make the PCB look polished and professional, ideal for marketing prototypes or premium electronics. However, it’s worth noting that glossy finishes may show fingerprints or scratches more easily during handling, so they might not be the best choice for rugged applications.

2. Matte Red Solder Mask Finish

For a more understated look, a matte red solder mask finish offers a non-reflective, smooth surface. This finish is less prone to showing smudges or minor imperfections, making it a practical choice for industrial or frequently handled PCBs. Matte finishes also reduce glare under bright lighting, which can be beneficial during inspections or assembly. Many designers prefer matte red for its modern, subtle elegance that still delivers the bold color impact.

3. Semi-Gloss Red Solder Mask Finish

If you’re looking for a balance between glossy and matte, a semi-gloss red solder mask finish might be the perfect compromise. It provides a slight sheen without being overly reflective, offering a clean and professional appearance. This finish is versatile and works well for a wide range of applications, from consumer electronics to industrial control boards. It also tends to be more resistant to minor wear compared to a full glossy finish.

Each of these red solder mask finish options can be paired with different surface finishes for the exposed copper pads, such as HASL (Hot Air Solder Leveling), ENIG (Electroless Nickel Immersion Gold), or OSP (Organic Solderability Preservative). For instance, pairing a matte red solder mask with ENIG can create a premium look with excellent solderability, ensuring reliable connections with a flatness tolerance of less than 0.1 mil for fine-pitch components.

Practical Considerations for Red PCB Board Design

While the visual benefits of a red PCB board design are clear, there are several practical factors to consider before finalizing your choice. These considerations ensure that the red solder mask aligns with your project’s technical and budgetary requirements.

Cost Implications

Red solder mask is often slightly more expensive than traditional green due to the specialized pigments and manufacturing processes involved. On average, the cost increase can range from 5% to 10% per board for small to medium production runs. However, for large-scale manufacturing, the price difference becomes negligible. If budget is a concern, weigh the aesthetic and visibility benefits against the added cost to determine if red is the right choice.

Inspection Challenges

While red enhances visibility for component placement, it may pose challenges during automated optical inspection (AOI). Some AOI systems are calibrated for green or other high-contrast masks, and the red color might require adjustments to lighting or software settings to detect defects accurately. Before committing to a red solder mask, consult with your manufacturing partner to ensure compatibility with their inspection processes.

Application Suitability

Consider the environment in which your PCB will operate. Red solder mask materials typically offer the same thermal and chemical resistance as other colors, withstanding temperatures up to 260°C during reflow soldering. However, in applications with intense UV exposure, some red pigments may fade over time. If your board will be used outdoors or under harsh lighting, opt for a UV-resistant red solder mask formulation to maintain its appearance.

Benefits of Partnering with a Trusted PCB Manufacturer for Red Solder Mask

Achieving the perfect red solder mask PCB appearance requires precision and expertise in manufacturing. Partnering with a reliable PCB provider ensures that the color consistency, finish quality, and protective properties of the solder mask meet your expectations. A trusted manufacturer will offer customization options for red solder mask finish types and provide guidance on selecting the best combination of materials for your design.

Moreover, advanced manufacturing processes can guarantee uniform application of the red solder mask, avoiding issues like uneven coating or pinholes that could compromise the board’s protection. For high-density designs with trace widths as small as 3 mils, precise solder mask application is critical to prevent shorts or exposure of copper traces. Working with an experienced provider also gives you access to quality control measures, ensuring that each board passes rigorous testing for electrical performance and durability.

Tips for Designing with Red Solder Mask

To maximize the benefits of a red PCB board design, keep these design tips in mind:

- Optimize Silkscreen Contrast: Use white or yellow silkscreen markings for maximum readability against the red background. This ensures that component labels and reference designators are easy to read.

- Test Visibility Early: Create a prototype with a red solder mask to evaluate visibility under your specific assembly or usage conditions. Adjust the finish or color shade if needed.

- Consider Layer Stackup: For multilayer boards, ensure that the red solder mask is applied consistently across all exposed layers for a cohesive look. This is especially important for edge connectors or visible side profiles.

- Balance Aesthetics and Function: While red is visually striking, prioritize functional requirements like thermal performance and signal integrity over appearance. For high-speed designs, ensure the solder mask dielectric constant (typically around 3.5 to 4.0 at 1 MHz) supports your impedance needs.

Conclusion: Make a Bold Statement with Red Solder Mask

Red solder mask is more than just a color choice—it’s a design decision that can elevate your PCB’s appearance, enhance hardware visibility, and align with your branding goals. From the striking red solder mask PCB appearance to the practical benefits of improved component visibility, this option offers a unique blend of style and functionality. With various red solder mask finish options like glossy, matte, and semi-gloss, you can customize the look to suit your project’s needs.

Whether you’re designing a consumer gadget, an industrial controller, or a custom prototype, a red PCB board design can make a lasting impact. By understanding the practical considerations and partnering with a trusted manufacturer, you can ensure that your red solder mask PCB not only looks great but also performs reliably. Ready to bring your vision to life with a bold, vibrant design? Start exploring the possibilities of red solder mask today!

ALLPCB

ALLPCB