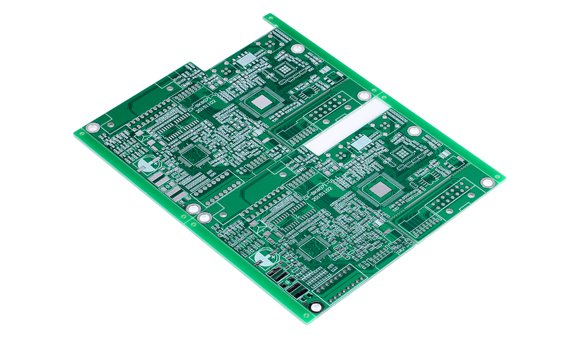

When it comes to designing printed circuit boards (PCBs) for oil rig monitoring, selecting the right materials is crucial. Oil rigs operate in some of the harshest environments on Earth, with extreme temperatures, high humidity, corrosive saltwater, and constant vibrations. The best PCB materials for oil rig applications are those with high thermal resistance, durability, and stability under stress, such as high Tg substrates, polyimide, and specialized laminates like Rogers materials. In this comprehensive guide, we’ll explore the top PCB materials for oil rig monitoring and help you choose the best substrates for extreme conditions.

Why PCB Material Selection Matters for Oil Rig Monitoring

Oil rig monitoring systems are vital for ensuring safety, efficiency, and productivity in the oil and gas industry. These systems track critical data like pressure, temperature, and equipment performance in real-time. However, the PCBs in these systems must withstand brutal conditions, including temperature swings from -40°C to over 150°C, exposure to chemicals, and mechanical stress from vibrations. Choosing the wrong material can lead to PCB failure, resulting in costly downtime or even safety hazards.

The key to reliable performance lies in selecting PCB substrates designed for extreme environments. Materials with high glass transition temperatures (Tg), excellent thermal conductivity, and resistance to moisture and corrosion are essential for oil rig applications. Let’s dive into the specific materials that meet these demands and why they are ideal for such challenging conditions.

Key Challenges of Extreme Conditions on Oil Rigs

Before exploring specific PCB materials, it’s important to understand the unique challenges oil rig environments pose to electronic components:

- Extreme Temperatures: Oil rigs often face sub-zero temperatures in Arctic regions or intense heat in desert locations. PCBs must operate reliably across a wide temperature range without warping or degrading.

- High Humidity and Corrosion: Offshore rigs are exposed to saltwater and high humidity, which can corrode standard PCB materials and cause short circuits.

- Vibrations and Mechanical Stress: Constant drilling and heavy machinery create vibrations that can crack or delaminate weaker PCB substrates.

- Chemical Exposure: Oil, grease, and other chemicals can degrade materials not designed to resist such substances.

With these challenges in mind, the right PCB materials must offer thermal stability, mechanical strength, and resistance to environmental factors. Let’s look at the top choices for oil rig monitoring systems.

High Tg PCB Materials: Built for Thermal Stability

High Tg (glass transition temperature) PCB materials are a popular choice for applications requiring thermal resistance. The Tg value indicates the temperature at which a PCB substrate transitions from a rigid to a more flexible state. For oil rig monitoring, where temperatures can exceed 150°C, high Tg materials (typically above 170°C) prevent deformation and maintain structural integrity.

These materials are often based on advanced epoxy resins that provide better heat resistance compared to standard FR-4 substrates, which have a Tg of around 130-140°C. High Tg laminates can handle thermal cycling—repeated heating and cooling—without cracking or losing electrical performance. For instance, a high Tg material with a value of 180°C ensures that the PCB remains stable even during prolonged exposure to heat near drilling equipment.

High Tg PCB materials are ideal for oil rig monitoring because they offer:

- Improved thermal endurance for high-temperature environments.

- Reduced risk of delamination during thermal expansion.

- Better mechanical strength to withstand vibrations.

If your oil rig project involves sustained high temperatures, high Tg substrates should be at the top of your list for ensuring long-term reliability.

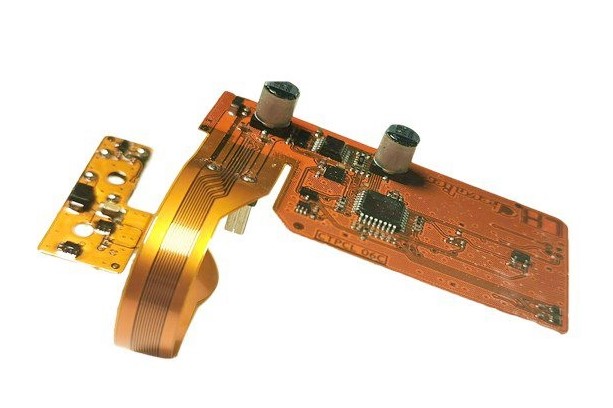

Polyimide PCB Materials: Flexibility and Heat Resistance

Polyimide PCB materials are another excellent choice for oil rig monitoring systems, especially when flexibility and extreme temperature resistance are needed. Polyimide substrates can withstand continuous use at temperatures up to 240°C and short-term exposure to as high as 400°C. This makes them perfect for environments where heat spikes are common, such as near oil extraction equipment.

One of the standout features of polyimide is its flexibility. Unlike rigid substrates, polyimide can be used in flexible or rigid-flex PCBs, which are useful for compact or irregularly shaped monitoring devices on oil rigs. Additionally, polyimide offers excellent resistance to chemicals and moisture, protecting the PCB from corrosion caused by saltwater or oil exposure.

Key benefits of polyimide PCB materials for oil rigs include:

- Exceptional heat resistance for extreme temperature environments.

- Flexibility for innovative design layouts in confined spaces.

- High resistance to chemical degradation and moisture.

For oil rig applications where space is limited and temperatures soar, polyimide provides a robust solution that ensures both performance and durability.

Rogers PCB Materials: High-Performance for Oil and Gas Applications

For oil and gas applications requiring high-frequency performance alongside durability, Rogers PCB materials stand out. These advanced laminates, often based on hydrocarbon ceramics, are designed for high-speed and microwave applications. They offer a low dielectric constant and excellent thermal stability, making them suitable for sophisticated monitoring systems on oil rigs that rely on precise signal integrity.

Rogers materials, such as those in the RO4000 series, have a Tg value exceeding 280°C in some cases, ensuring they can handle the harshest thermal conditions. Their low thermal expansion coefficient (CTE) means they resist warping during temperature changes, which is critical for maintaining signal accuracy in sensors and communication devices. For example, a Rogers laminate with a dielectric constant of 3.38 ensures minimal signal loss, even at frequencies up to 10 GHz, which is often necessary for real-time data transmission on oil rigs.

Advantages of Rogers PCB materials in oil and gas monitoring include:

- Superior high-frequency performance for accurate data transmission.

- High thermal stability with Tg values well above standard materials.

- Low moisture absorption to prevent corrosion in humid environments.

While Rogers materials may come at a higher cost, their unmatched performance in extreme conditions makes them a worthy investment for critical oil rig monitoring systems.

Comparing PCB Materials for Oil Rig Monitoring

To help you choose the best substrate for your oil rig project, let’s compare high Tg materials, polyimide, and Rogers laminates based on key factors:

| Material | Tg Value (°C) | Temperature Range (°C) | Flexibility | High-Frequency Performance | Cost |

|---|---|---|---|---|---|

| High Tg Epoxy | 170-180 | -40 to 150 | Rigid | Moderate | Moderate |

| Polyimide | 250+ | -40 to 400 (short-term) | Flexible | Moderate | High |

| Rogers Laminates | 280+ | -40 to 200+ | Rigid | Excellent | High |

From this comparison, high Tg materials are a cost-effective choice for general-purpose monitoring under moderate extreme conditions. Polyimide excels in scenarios requiring flexibility and the highest temperature resistance. Rogers materials are the go-to option for applications where high-frequency performance and signal integrity are non-negotiable.

Factors to Consider When Choosing PCB Materials for Oil Rigs

Selecting the right PCB substrate for oil rig monitoring involves evaluating several factors beyond just material properties. Here are the main considerations to keep in mind:

- Operating Temperature Range: Match the material’s Tg and thermal endurance to the expected temperature extremes of your rig’s location.

- Signal Requirements: For high-frequency or microwave applications, prioritize materials with low dielectric loss, such as Rogers laminates.

- Environmental Exposure: Choose substrates with low moisture absorption and chemical resistance for offshore rigs exposed to saltwater and oil.

- Mechanical Durability: Ensure the material can withstand vibrations and shocks from drilling operations without cracking or delaminating.

- Budget Constraints: Balance performance with cost, as advanced materials like polyimide and Rogers laminates can be more expensive.

By carefully assessing these factors, you can narrow down the best PCB material for your specific oil rig monitoring needs.

Design Tips for PCBs in Extreme Oil Rig Conditions

Beyond choosing the right material, optimizing your PCB design can further enhance performance in extreme conditions. Here are some practical tips:

- Use Thicker Copper Layers: Opt for copper thicknesses of 2 oz or more to improve heat dissipation and withstand thermal stress.

- Incorporate Thermal Vias: Add thermal vias to transfer heat away from critical components, preventing overheating in high-temperature zones.

- Apply Conformal Coating: Protect the PCB from moisture and corrosion by applying a conformal coating resistant to saltwater and chemicals.

- Minimize Component Density: Space out components to reduce heat buildup and allow for better airflow in hot environments.

These design strategies, combined with the right substrate, will maximize the lifespan and reliability of your PCB in the harsh conditions of an oil rig.

Conclusion: Building Reliable PCBs for Oil Rig Monitoring

Designing PCBs for oil rig monitoring requires careful consideration of the extreme conditions these systems face. High Tg PCB materials provide a cost-effective solution for thermal stability, polyimide offers unmatched flexibility and heat resistance, and Rogers laminates deliver top-tier performance for high-frequency applications in the oil and gas industry. By understanding the unique demands of your project—whether it’s temperature range, signal integrity, or environmental exposure—you can select the ideal substrate to ensure reliability and safety.

At ALLPCB, we’re committed to helping you navigate the complexities of PCB design for extreme environments. Whether you’re working on oil rig monitoring systems or other challenging applications, our expertise and wide range of material options can support your project from concept to completion. Choose the right PCB materials for oil rig applications and build systems that stand up to the toughest conditions.