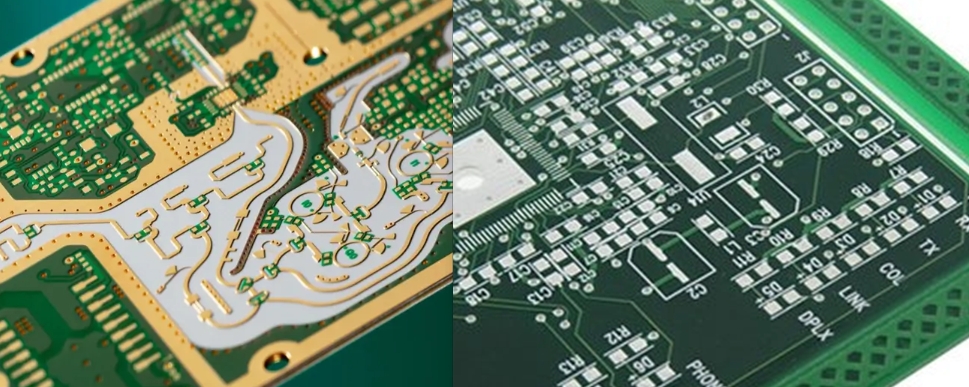

When designing high-frequency PCBs for GHz applications, selecting the right surface finish is critical for ensuring signal integrity and performance. Two popular options, Electroless Nickel Immersion Gold (ENIG) and Immersion Silver, often come up in discussions about high frequency PCB surface finish comparison. But which one is better for your project? In short, ENIG offers excellent corrosion resistance and durability but may introduce slight ENIG signal loss at GHz frequencies due to the nickel layer. On the other hand, Immersion Silver provides superior Immersion Silver conductivity for better signal integrity, though it is prone to tarnishing over time. This blog dives deep into the pros, cons, and technical details of both finishes to help you make an informed decision for your GHz PCB assembly and ensure optimal surface finish for signal integrity.

Why Surface Finish Matters in High-Frequency PCB Design

In high-frequency PCB designs operating at GHz frequencies, every detail counts. The surface finish on your PCB not only protects the copper traces from oxidation but also impacts how signals travel through the board. At GHz frequencies, even small losses or interferences can degrade performance, leading to issues like data errors or reduced system efficiency. A well-chosen surface finish minimizes signal loss, maintains impedance control, and ensures reliable soldering during assembly.

For applications like 5G technology, radar systems, and high-speed digital circuits, the stakes are even higher. The surface finish must support fast signal transmission while resisting environmental factors like humidity and temperature changes. This is why understanding the differences between finishes like ENIG and Immersion Silver is so important for engineers working on GHz PCB assembly.

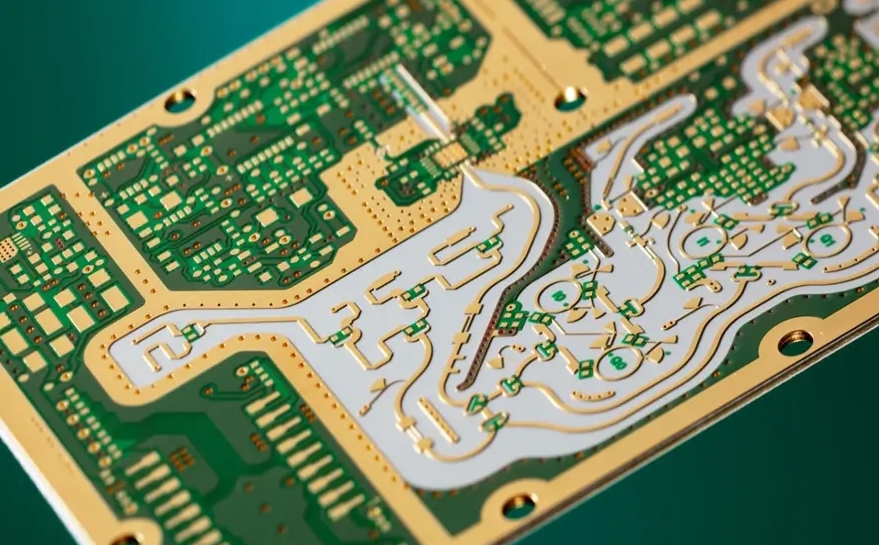

What is ENIG? Understanding Its Role in PCB Design

Electroless Nickel Immersion Gold, commonly known as ENIG, is a two-layer surface finish widely used in PCB manufacturing. It consists of a thin layer of nickel (typically 3-6 micrometers) deposited over the copper, followed by an even thinner layer of gold (about 0.05-0.1 micrometers). The nickel acts as a barrier to prevent copper diffusion, while the gold protects the nickel from oxidation and ensures excellent solderability.

ENIG is a popular choice for many applications due to its durability and resistance to corrosion. It performs well in harsh environments and supports multiple reflow cycles during assembly without degrading. However, when it comes to high-frequency designs, the nickel layer can introduce challenges related to ENIG signal loss, which we’ll explore in detail later.

Advantages of ENIG for GHz PCB Design

- Corrosion Resistance: The gold layer prevents oxidation, making ENIG ideal for long-term reliability in humid or corrosive environments.

- Flat Surface: ENIG provides a uniform, flat finish, which is crucial for fine-pitch components often used in GHz PCB assembly.

- Durability: It withstands multiple soldering cycles without significant wear, ensuring consistent performance during manufacturing.

Disadvantages of ENIG in High-Frequency Applications

- Signal Loss: The nickel layer in ENIG has lower conductivity than copper or silver, leading to potential ENIG signal loss at GHz frequencies due to the skin effect (where signals travel near the surface of conductors).

- Higher Cost: ENIG is more expensive than other finishes due to the materials and process complexity, which may impact budget-conscious projects.

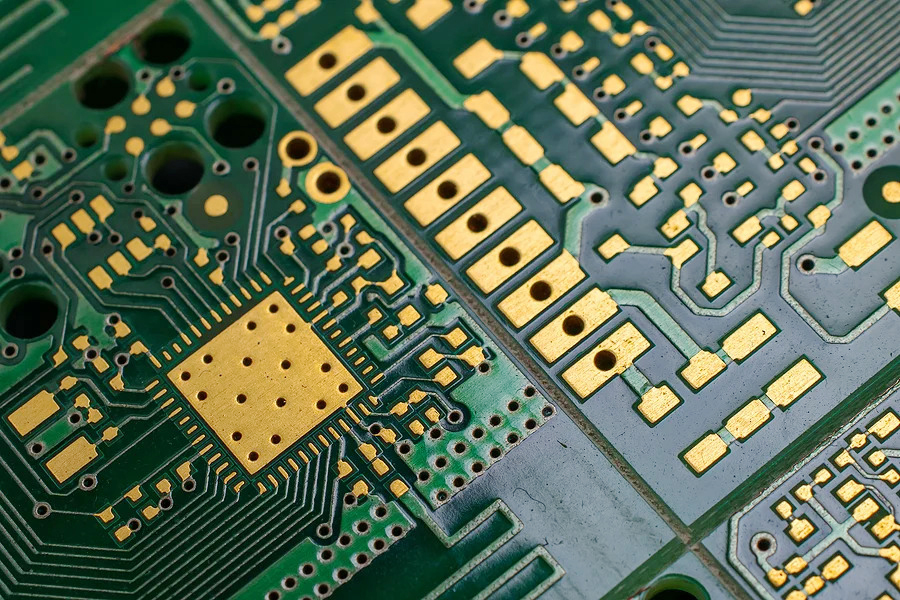

What is Immersion Silver? A Conductive Choice for Signal Integrity

Immersion Silver is a single-layer surface finish where a thin layer of silver (typically 0.1-0.3 micrometers) is chemically deposited directly onto the copper traces. This finish is known for its excellent conductivity, making it a strong candidate for applications prioritizing surface finish for signal integrity. Silver has the highest electrical conductivity of any metal, which translates to minimal signal loss even at GHz frequencies.

While Immersion Silver offers clear advantages for high-frequency designs, it comes with some trade-offs, particularly in terms of environmental stability. Let’s break down its strengths and weaknesses for GHz PCB assembly.

Advantages of Immersion Silver for GHz PCB Design

- Superior Conductivity: With Immersion Silver conductivity being close to that of bare copper, it minimizes signal loss, making it ideal for high-frequency applications operating at 1 GHz and above.

- Cost-Effective: Compared to ENIG, Immersion Silver is generally less expensive, offering a budget-friendly option without sacrificing performance.

- Flat Surface: Like ENIG, it provides a smooth, uniform finish, which is beneficial for fine-pitch components and high-density designs.

Disadvantages of Immersion Silver in High-Frequency Applications

- Tarnishing Risk: Silver is prone to oxidation and tarnishing when exposed to air or sulfur-containing environments, which can degrade performance over time if not handled properly.

- Limited Shelf Life: Due to tarnishing, Immersion Silver PCBs often have a shorter shelf life compared to ENIG, requiring careful storage and timely assembly.

High Frequency PCB Surface Finish Comparison: ENIG vs. Immersion Silver

Now that we’ve covered the basics of both finishes, let’s dive into a detailed high frequency PCB surface finish comparison focusing on key factors like signal integrity, cost, and environmental stability. This side-by-side analysis will help you decide which finish aligns best with your project’s needs for GHz PCB assembly.

Signal Integrity at GHz Frequencies

Signal integrity is paramount in high-frequency designs. At GHz frequencies, the skin effect causes signals to travel primarily on the surface of conductors, making the surface finish a critical factor. Immersion Silver excels here due to its high conductivity, often resulting in insertion losses as low as 0.1 dB/inch at 10 GHz on standard FR-4 material. In contrast, ENIG’s nickel layer can increase insertion loss to around 0.2-0.3 dB/inch at the same frequency due to its lower conductivity and magnetic properties, contributing to ENIG signal loss.

For applications like 5G base stations or high-speed data links where every fraction of a decibel matters, Immersion Silver often provides better performance for surface finish for signal integrity. However, proper handling and storage are necessary to prevent tarnishing, which could negate these benefits over time.

Impedance Control

Maintaining controlled impedance is crucial for high-frequency circuits to prevent signal reflections and ensure consistent performance. Both ENIG and Immersion Silver offer a flat, uniform surface that supports precise impedance control, typically within ±10% tolerance on standard designs. However, the thinner layer of Immersion Silver (compared to the combined nickel and gold of ENIG) can sometimes result in slightly tighter impedance values, closer to ±5% in optimized processes, benefiting designs requiring extreme precision.

Environmental Stability and Durability

ENIG shines in terms of environmental stability. Its gold layer resists oxidation and corrosion, making it suitable for PCBs exposed to harsh conditions or requiring a long shelf life. Immersion Silver, while initially effective, can tarnish within months if not stored in a sulfur-free environment or protected with anti-tarnish coatings. For projects where reliability over extended periods is critical, ENIG often takes the lead.

Cost Considerations

Cost is always a factor in PCB design. ENIG typically costs 20-30% more than Immersion Silver due to the materials (gold) and the complexity of the plating process. For large-scale production or budget-sensitive projects, Immersion Silver may be the more economical choice, provided its environmental limitations are managed.

Practical Applications: When to Choose ENIG or Immersion Silver

Choosing between ENIG and Immersion Silver depends on the specific requirements of your high-frequency PCB project. Here are some scenarios to guide your decision:

- Choose ENIG: If your design prioritizes long-term reliability and will be exposed to harsh environments (e.g., outdoor 5G equipment or automotive radar systems), ENIG’s corrosion resistance makes it the better option. It’s also suitable for projects where multiple reflow cycles are expected during assembly.

- Choose Immersion Silver: For applications where signal integrity is the top priority and cost is a concern (e.g., high-speed data transfer devices or consumer electronics), Immersion Silver’s superior conductivity and lower price point are advantageous. Ensure proper storage and quick assembly to mitigate tarnishing risks.

Tips for Optimizing Surface Finish Performance in GHz Designs

Regardless of which finish you choose, optimizing your PCB design and manufacturing process can enhance performance. Here are some practical tips:

- Minimize Trace Lengths: Shorter traces reduce signal loss, complementing the benefits of a high-conductivity finish like Immersion Silver.

- Use Low-Loss Materials: Pair your surface finish with low dielectric constant (Dk) materials like PTFE or high-frequency laminates to further improve signal integrity.

- Protect Against Tarnishing: If using Immersion Silver, store PCBs in vacuum-sealed or anti-tarnish packaging to extend shelf life.

- Simulate Signal Performance: Use simulation tools to model insertion loss and impedance with your chosen finish before finalizing the design. For instance, expect a 50-ohm trace on FR-4 to vary by 1-2 ohms depending on the finish at 5 GHz.

Conclusion: Making the Right Choice for Your High-Frequency PCB

Selecting the right surface finish for your high-frequency PCB design is a balancing act between performance, cost, and environmental factors. In this high frequency PCB surface finish comparison, ENIG stands out for its durability and corrosion resistance, making it ideal for long-term reliability in challenging conditions. However, it may introduce ENIG signal loss at GHz frequencies due to the nickel layer. Immersion Silver, with its excellent Immersion Silver conductivity, offers superior signal integrity for GHz PCB assembly, though it requires careful handling to avoid tarnishing.

By understanding the specific needs of your project—whether it’s minimizing signal loss or ensuring durability—you can choose the best surface finish for signal integrity. At ALLPCB, we’re committed to supporting your high-frequency designs with tailored solutions and expert guidance. Whether you opt for ENIG or Immersion Silver, our manufacturing processes ensure top-quality results for your GHz applications.

ALLPCB

ALLPCB