Component selection plays a critical role in Surface Mount Technology (SMT) assembly, directly affecting both the cost and performance of the final product. When building a Bill of Materials (BOM) for your project, choosing the right SMT components can save money, improve efficiency, and ensure high-quality results. Factors like component cost, sourcing challenges, and performance specifications all come into play. In this comprehensive guide, we’ll explore how these decisions impact your SMT assembly process and provide actionable insights to optimize your designs for cost and performance.

Why Component Selection Matters in SMT Assembly

In SMT assembly, every component on your BOM contributes to the overall cost and functionality of the printed circuit board (PCB). Selecting the wrong capacitor, resistor, or integrated circuit (IC) can lead to higher production expenses, assembly delays, or even performance failures. For engineers and manufacturers, understanding the balance between cost and quality is essential. Poor choices can result in increased rework, higher defect rates, or boards that fail to meet design specifications, such as signal integrity or thermal management.

By focusing on smart component selection, you can reduce assembly costs by minimizing errors and streamlining production. At the same time, choosing components with the right performance characteristics ensures your design operates reliably under real-world conditions. Let’s dive into the key factors that influence these outcomes.

Understanding SMT Components and Their Role in Assembly

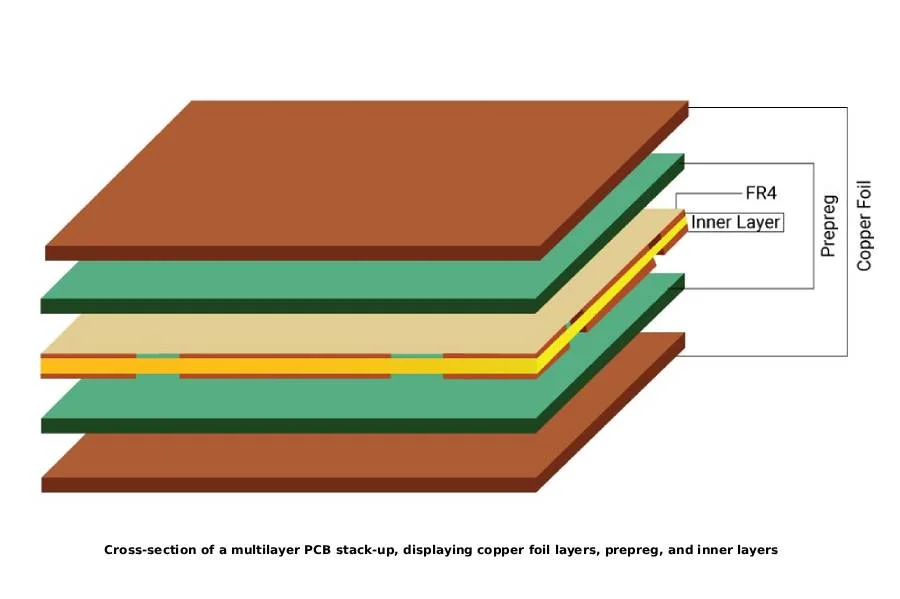

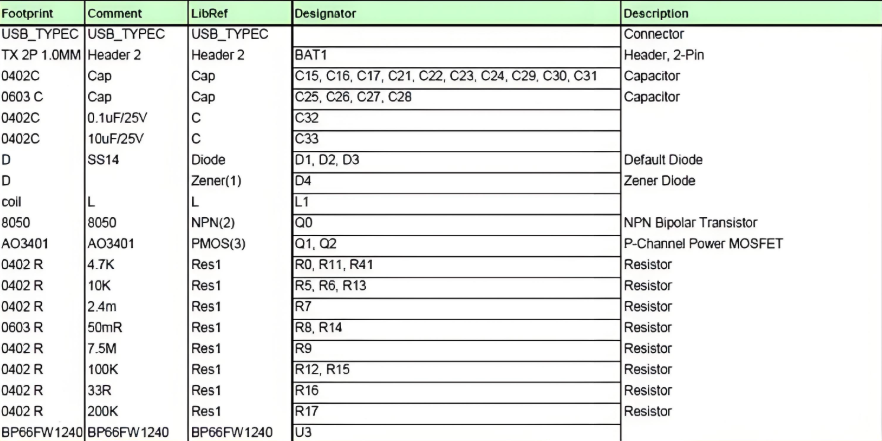

SMT components are the building blocks of modern electronics, designed to be mounted directly onto the surface of a PCB. These components come in various shapes and sizes, from tiny 0201 resistors (0.6mm x 0.3mm) to larger ICs with hundreds of pins. Common types include resistors, capacitors, diodes, transistors, and microcontrollers, each with specific electrical properties that affect circuit performance.

The assembly process for SMT involves automated pick-and-place machines that position components with precision, followed by reflow soldering to secure them in place. The choice of components impacts how smoothly this process runs. For instance, components with non-standard packaging may require special machine setups, increasing assembly time and cost. Similarly, components with tight tolerances or unique thermal profiles can complicate soldering, leading to defects like tombstoning or insufficient solder joints.

With SMT making up around 90% of board assemblies today, as noted in industry resources, the stakes are high for getting component selection right. A well-thought-out BOM not only ensures compatibility with assembly equipment but also enhances the overall reliability of the final product.

How Component Cost Affects SMT Assembly Budgets

One of the most immediate impacts of component selection is on the overall cost of your SMT assembly. Component cost varies widely based on factors like availability, manufacturer, and specifications. For example, a standard 1kΩ resistor in a 0603 package might cost just a few cents per unit, while a high-precision, low-temperature-coefficient resistor for the same value could cost ten times more.

Bulk purchasing can lower per-unit costs, but it requires careful planning. Sourcing components in large quantities might save money upfront, but if the project scope changes or components become obsolete, you risk tying up capital in unused inventory. On the other hand, sourcing rare or specialized components in small batches often comes with higher prices and longer lead times, delaying production and increasing costs.

Another cost factor is the compatibility of components with automated assembly. Components that require manual placement or custom handling can drive up labor expenses. For instance, a component with a non-standard footprint might need a specialized nozzle on a pick-and-place machine, adding setup time and cost. By prioritizing components with standard packaging (like tape-and-reel formats) and widely available footprints, you can keep assembly costs under control.

The Role of Sourcing in Component Selection

Sourcing SMT components is a balancing act between cost, availability, and reliability. Where and how you source your components can significantly impact both assembly cost and project timelines. Reliable suppliers ensure consistent quality and timely delivery, while poor sourcing decisions can lead to counterfeit parts, supply chain delays, or mismatched specifications.

When sourcing components, consider the lead time for each part. For example, during global chip shortages, lead times for certain microcontrollers have stretched from weeks to months, forcing manufacturers to pay premium prices or redesign boards with alternative parts. Planning ahead and building a BOM with multiple sourcing options for critical components can mitigate these risks.

Another sourcing consideration is the geographic location of suppliers. Local suppliers might offer faster delivery but at a higher cost, while international suppliers could provide lower prices but with added shipping delays and customs fees. Building relationships with trusted distributors and maintaining a diversified supply chain can help manage these trade-offs.

Finally, always verify the authenticity of components, especially for high-value items like ICs. Counterfeit parts can lead to catastrophic failures, undermining performance and increasing rework costs. Using authorized distributors and implementing strict quality checks during incoming inspection can prevent such issues.

Performance Impacts of Component Selection

Beyond cost, component selection directly influences the performance of your PCB. Electrical characteristics like impedance, capacitance, and thermal resistance must align with your design requirements to ensure reliable operation. Let’s break down some key performance factors affected by component choice.

Signal Integrity and Speed

For high-speed designs, such as those in telecommunications or data processing, component selection is critical for maintaining signal integrity. Capacitors with high equivalent series resistance (ESR) or inductors with poor quality factors (Q-factor) can introduce noise or signal loss. For example, in a 5G application operating at frequencies above 3 GHz, using a capacitor with a low self-resonant frequency can degrade performance, leading to signal distortion.

Similarly, the physical size of components affects signal speed. Smaller SMT components reduce parasitic inductance and capacitance due to shorter lead lengths, enabling faster circuit operation. This is why high-density designs often use 0402 or even 0201 packages instead of larger 0805 components, despite the added assembly complexity.

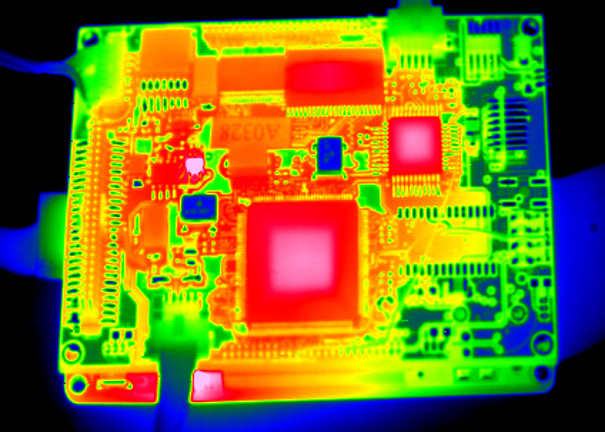

Thermal Management

Thermal performance is another critical area. Components that generate significant heat, like power transistors or voltage regulators, must have adequate thermal dissipation capabilities. Choosing a component with a low thermal resistance (measured in °C/W) ensures it can handle heat without degrading. For instance, a power MOSFET with a thermal resistance of 1.5°C/W will perform better under high current loads compared to one with 3°C/W, reducing the risk of overheating and extending lifespan.

Component placement also ties into thermal performance. Grouping heat-generating components too closely can create hot spots, while poor selection of thermal pads or vias can limit heat dissipation. Matching components to the board’s thermal design is essential for consistent performance.

Power Efficiency

In battery-powered devices, power efficiency is a top priority. Selecting components with low power consumption, such as low-quiescent-current voltage regulators or high-efficiency LEDs, can extend battery life. For example, a regulator with a quiescent current of 1μA instead of 10μA can make a noticeable difference in standby power draw for wearable devices.

Strategies for Optimizing Component Selection

With both cost and performance at stake, optimizing component selection requires a strategic approach. Here are practical steps to guide your decision-making process for SMT assembly.

Standardize Components Where Possible

Using standardized components across multiple designs reduces inventory complexity and leverages bulk purchasing discounts. For instance, sticking to a limited set of resistor and capacitor values (like 1kΩ, 10kΩ, and 100kΩ) simplifies sourcing and minimizes the risk of stock shortages. Standardization also streamlines assembly by reducing the number of unique setups required for pick-and-place machines.

Prioritize Design for Manufacturability (DFM)

Design for Manufacturability principles ensure your BOM aligns with assembly capabilities. Choose components with footprints and packaging compatible with automated equipment to avoid manual intervention. Additionally, check component datasheets for reflow soldering profiles to confirm they match your assembly process, preventing defects like cracked capacitors or lifted pads.

Balance Cost and Quality

While it’s tempting to opt for the cheapest components, cutting corners can backfire. A low-cost capacitor with a high failure rate might save a few cents per unit but lead to costly rework or field failures. Instead, evaluate the total cost of ownership, factoring in reliability, lifespan, and potential downtime. Investing in slightly more expensive, high-quality components often pays off in the long run.

Leverage Simulation Tools

Before finalizing your BOM, use simulation software to test component performance under expected operating conditions. Tools can model signal integrity, thermal behavior, and power consumption, helping identify potential issues before assembly. For example, simulating a high-frequency circuit might reveal that a chosen inductor causes excessive ripple, prompting a switch to a higher-quality alternative.

Common Pitfalls in Component Selection and How to Avoid Them

Even experienced engineers can encounter challenges during component selection. Here are some common pitfalls and tips to avoid them.

Overlooking Obsolescence: Components can become obsolete, leaving you scrambling for replacements mid-production. Always check the lifecycle status of parts and have alternative options listed in your BOM to avoid delays.

Ignoring Minimum Order Quantities (MOQ): Some components have high MOQs, forcing you to buy more than needed. Factor MOQs into cost calculations to avoid excess inventory.

Mismatching Specifications: A resistor with the wrong power rating or a capacitor with insufficient voltage tolerance can fail under load. Double-check datasheets to ensure components meet design requirements.

Underestimating Lead Times: Long lead times can halt production. Build buffer time into your schedule and source critical components early to prevent bottlenecks.

Conclusion: Making Informed Decisions for SMT Assembly Success

Component selection is a cornerstone of successful SMT assembly, influencing both the cost and performance of your PCB. By carefully evaluating component cost, sourcing options, and performance characteristics, you can create a BOM that balances affordability with reliability. Standardizing parts, prioritizing manufacturability, and leveraging simulation tools are just a few ways to optimize your choices. With thoughtful planning, you can minimize assembly challenges, reduce expenses, and deliver high-performing electronics that meet or exceed expectations.

At ALLPCB, we’re committed to supporting your SMT assembly projects with expert guidance and reliable services. Whether you’re sourcing components or finalizing your design, our team is here to help you achieve the best results. Focus on smart component selection, and watch your projects thrive in both cost-efficiency and performance.

ALLPCB

ALLPCB