In the fast-paced world of electronics, engineers face increasing pressure to design printed circuit boards (PCBs) that are efficient, scalable, and cost-effective. Modular PCB design, paired with reusable component libraries, offers a powerful solution to streamline the design process, reduce errors, and accelerate time-to-market. By breaking down complex circuits into manageable, reusable modules, engineers can enhance flexibility and maintain consistency across projects. In this blog, we explore the principles of modular PCB design, the role of reusable component libraries, and practical strategies to implement them effectively.

Whether you're designing a high-speed communication system or a compact IoT device, understanding modularity can transform your workflow. Let's dive into how this approach can elevate your PCB designs.

What Is Modular PCB Design?

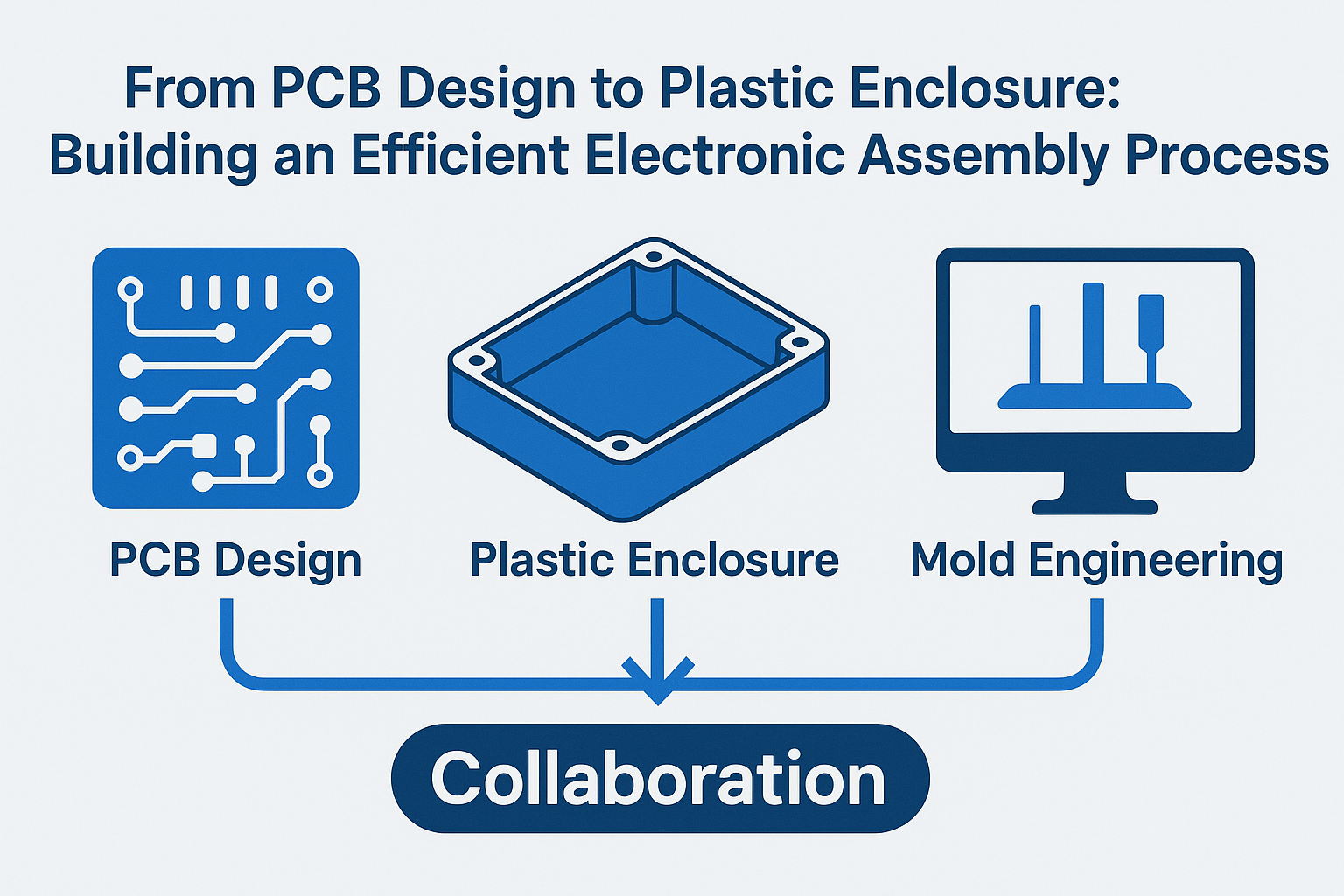

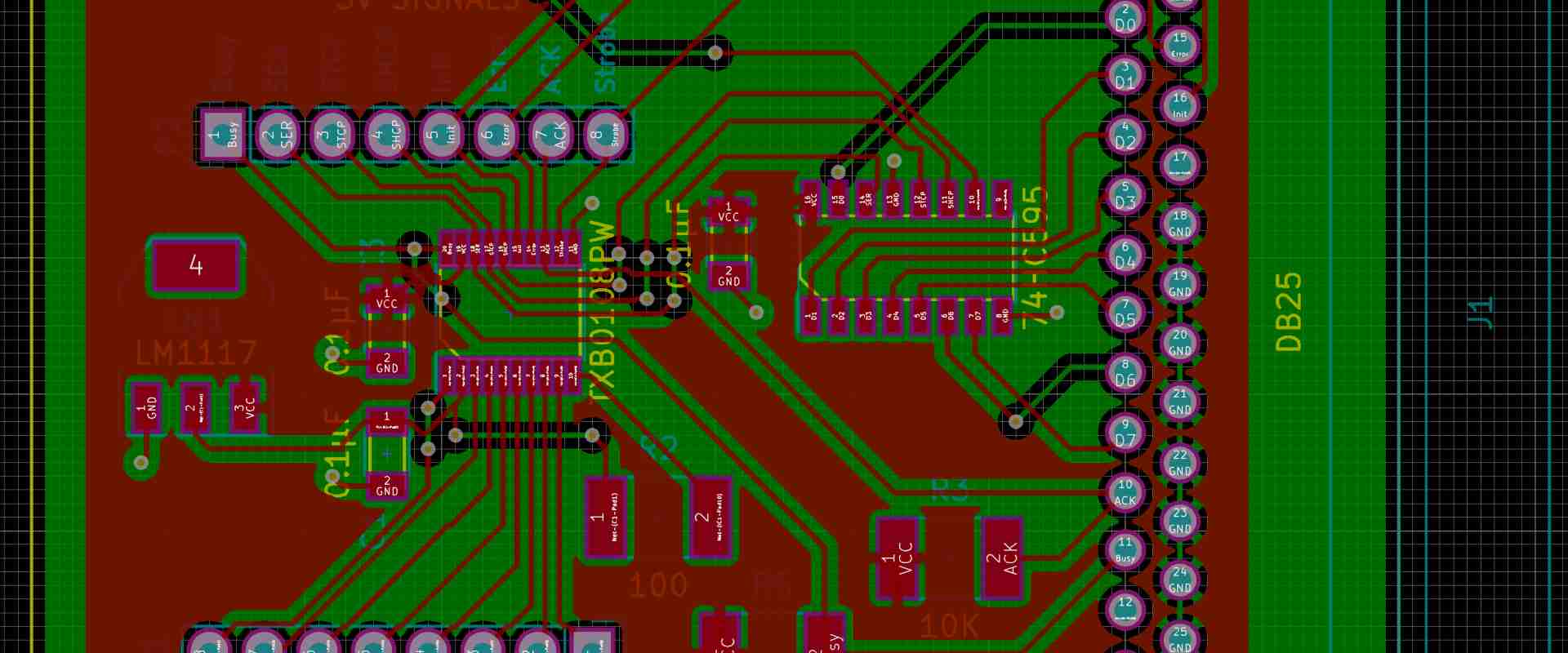

Modular PCB design involves dividing a circuit board into distinct functional blocks or modules, each performing a specific task, such as power management, signal processing, or communication. These modules are designed to be independent yet interoperable, allowing engineers to reuse them across different projects or configurations. Unlike traditional PCB design, which often treats the board as a single, monolithic system, modular design emphasizes flexibility and scalability.

For example, a modular PCB for a consumer electronics device might include a power supply module, a microcontroller module, and a wireless communication module. Each module can be tested, validated, and reused in other designs, reducing the need to start from scratch. This approach is particularly valuable in applications like embedded systems, where signal integrity and component density are critical.

Benefits of Modular PCB Design

Modular PCB design offers several advantages that make it a go-to strategy for modern electronics engineering. Here are the key benefits:

1. Reduced Design Time

By reusing pre-validated modules, engineers can significantly cut down on design time. Instead of redesigning a power management circuit for every project, a proven module can be integrated with minimal adjustments. Studies suggest that modular design can reduce development time by up to 30% in complex projects.

2. Improved Scalability

Modular designs are inherently scalable. Need to add a new feature, like a 5G communication module? Simply integrate a new module without overhauling the entire board. This flexibility is crucial for industries like automotive and IoT, where product requirements evolve rapidly.

3. Enhanced Quality and Reliability

Using tested and validated modules minimizes the risk of errors. For instance, a power module with known impedance characteristics (e.g., 50 ohms for RF applications) ensures consistent performance across designs. This approach also simplifies debugging, as issues can be isolated to specific modules.

4. Cost Efficiency

Reusing modules reduces the need for new components and lowers inventory costs. For example, a single microcontroller module can be used across multiple product lines, enabling bulk purchasing and better pricing. Additionally, modular designs streamline testing and manufacturing, further cutting costs.

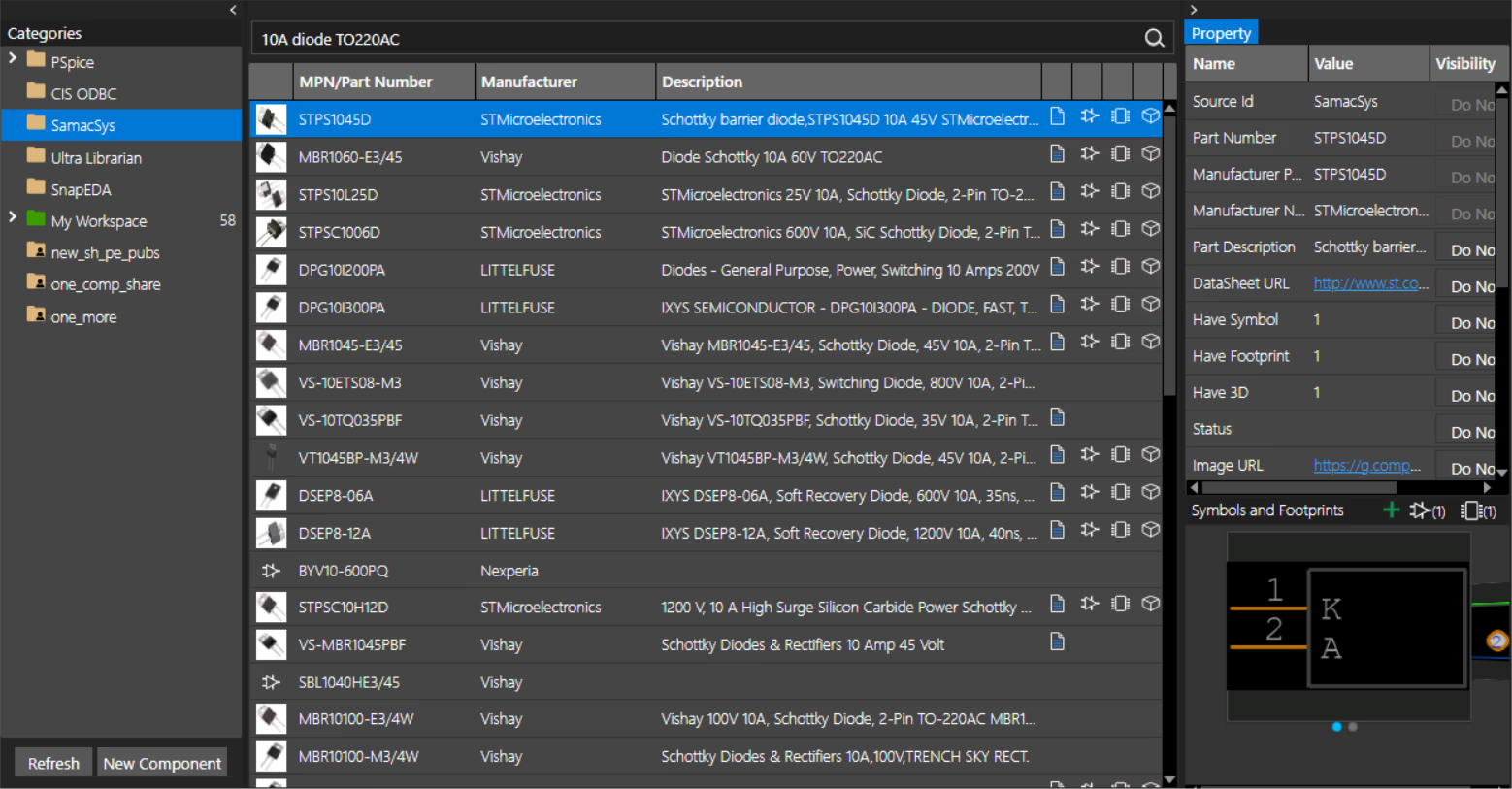

The Role of Reusable Component Libraries

Reusable component libraries are the backbone of modular PCB design. These libraries store pre-designed circuit blocks, schematics, and layouts that engineers can easily integrate into new projects. A well-organized library ensures consistency, reduces errors, and accelerates the design process.

What Makes a Good Component Library?

A robust component library should include:

- Comprehensive Schematics: Detailed schematics for each module, including pin assignments and signal paths.

- Validated Layouts: Pre-routed PCB layouts with defined layer stacks (e.g., a 4-layer stack with two routing layers and two planes for ground and power).

- Metadata: Information such as component specifications, performance metrics (e.g., signal speed up to 10 Gbps), and usage history.

- Compatibility: Support for industry-standard formats like Gerber and ODB++ to ensure seamless integration with design software.

Building an Effective Component Library

Creating a reusable component library requires careful planning. Here are the steps to get started:

- Identify Common Functions: Analyze your projects to identify frequently used circuits, such as voltage regulators, amplifiers, or USB interfaces. For example, a 3.3V regulator circuit with a 500 mA output is a common building block in IoT devices.

- Design and Validate Modules: Develop each module with clear electrical and geometrical interfaces. Test the module under real-world conditions, such as high-frequency signals (e.g., 2.4 GHz for Wi-Fi) to ensure reliability.

- Document Thoroughly: Include detailed documentation, such as impedance values, thermal performance, and signal integrity data. For instance, specify that a differential pair has a 100-ohm impedance to maintain signal integrity.

- Organize and Store: Use a data management system to categorize modules by function, application, or performance. Tools like Zuken's CR-8000 or Altium Designer offer built-in library management features.

Best Practices for Modular PCB Design

To maximize the benefits of modular PCB design and reusable component libraries, follow these best practices:

1. Standardize Interfaces

Ensure that modules use standardized electrical and mechanical interfaces, such as board-to-board connectors or pin headers. For example, a power module might use a 2.54 mm pitch connector to ensure compatibility across designs. This standardization simplifies integration and reduces design complexity.

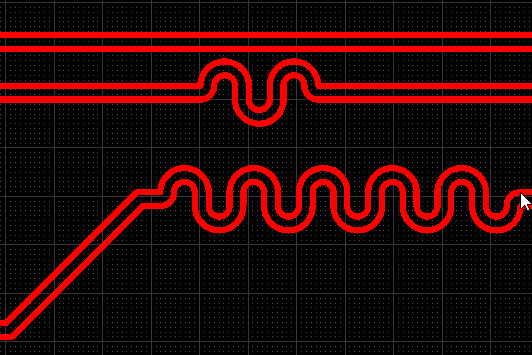

2. Prioritize Signal Integrity

High-speed designs, such as those for 5G or DDR memory, require careful attention to signal integrity. Use controlled impedance traces (e.g., 50 ohms for single-ended signals) and minimize crosstalk by separating analog and digital modules. Reusable libraries should include modules with pre-optimized routing to maintain performance.

3. Leverage Design Software

Modern PCB design softwares, such as KiCad, Altium Designer, or OrCAD, supports modular design through features like multi-channel schematic editing and component management. These tools allow engineers to drag and drop pre-designed modules from a library, saving time and reducing errors.

4. Test and Iterate

Before adding a module to your library, rigorously test it in multiple scenarios. For example, a communication module designed for 2.4 GHz Wi-Fi should be tested for interference and signal loss. Regular updates to the library based on testing feedback ensure long-term reliability.

Challenges and How to Overcome Them

While modular PCB design offers significant advantages, it comes with challenges that engineers must address:

1. Increased Initial Effort

Designing reusable modules requires upfront investment in time and resources. To mitigate this, start with high-impact modules that are used frequently, such as power or communication circuits, to maximize return on investment.

2. Compatibility Issues

Modules may not always align perfectly with new designs due to differences in form factor or electrical requirements. Using flexible design software with robust library management can help adapt modules to specific needs.

3. Version Control

Managing updates to a component library can be complex, especially in team environments. Implement a version control system to track changes and ensure that all team members use the latest module versions.

How ALLPCB Supports Modular PCB Design

For engineers looking to implement modular PCB design, ALLPCB offers a suite of services that streamline the process. Our quick-turn prototyping allows you to test and validate modules rapidly, ensuring they meet performance standards before integration. With advanced manufacturing capabilities, we support complex multilayer boards and high-density interconnects, ideal for modular designs. Our global logistics ensure fast delivery of prototypes and production runs, helping you meet tight project deadlines. By partnering with ALLPCB, you can focus on creating reusable, high-quality modules while we handle the manufacturing with precision and efficiency.

Conclusion

Modular PCB design, powered by reusable component libraries, is a game-changer for engineers seeking efficiency, scalability, and reliability. By breaking down complex circuits into manageable modules, you can reduce design time, lower costs, and improve product quality. A well-organized component library, standardized interfaces, and robust design software are key to success in this approach. While challenges like initial effort and compatibility exist, they can be overcome with strategic planning and the right tools.

ALLPCB

ALLPCB