In the fast-paced world of electronics, creating printed circuit boards (PCBs) that stand the test of time while remaining adaptable for future upgrades is a valuable skill. Whether you're an engineer, hobbyist, or manufacturer, building long-lasting PCB electronics with mods is the key to saving time, money, and resources. This guide dives deep into how you can design and modify PCBs for durability and flexibility, focusing on practical tips for electronics circuit upgrades, extending PCB electronics lifespan, and optimizing electronics manufacturing processes.

At its core, the secret to long-lasting PCB electronics lies in thoughtful design, quality materials, and strategic modifications (mods) that allow for future improvements without needing a complete redesign. Below, we'll explore actionable strategies to achieve this, ensuring your PCBs remain functional and upgradable for years to come.

Why Focus on Long-Lasting PCB Electronics with Mods?

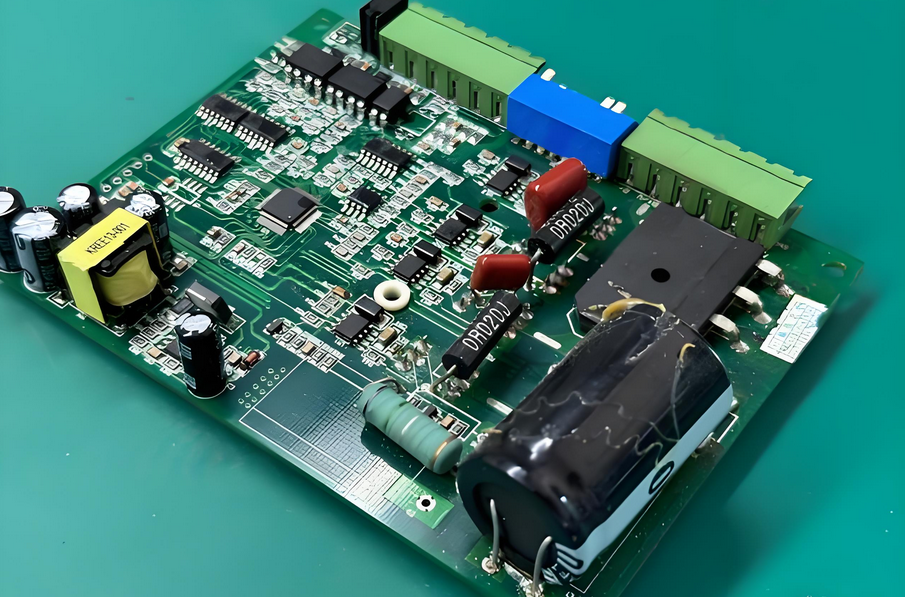

PCBs are the backbone of nearly every electronic device, from smartphones to industrial machinery. However, many designs fail prematurely due to poor planning, environmental stress, or obsolescence. By focusing on longevity and modularity during the design and manufacturing stages, you can avoid frequent replacements and reduce costs. Incorporating mods—custom tweaks or upgrades—into your PCB electronics ensures they can adapt to new technologies or performance needs without starting from scratch.

Designing for upgrades also aligns with sustainable practices, reducing electronic waste and supporting a circular economy. With the right approach, you can extend PCB electronics lifespan significantly, sometimes up to 50-70 years under optimal conditions, as noted in industry discussions on durable electronics.

Key Factors That Affect PCB Lifespan

Before diving into design and mod strategies, it's important to understand the factors that impact how long a PCB lasts. These elements play a critical role in determining whether your board will fail in a few years or endure for decades.

- Material Quality: The substrate (like FR-4) and copper thickness directly affect durability. For example, a 1 oz copper layer may suffice for low-power applications, but a 2 oz layer offers better heat dissipation and longevity for high-current designs.

- Environmental Conditions: Exposure to moisture, extreme temperatures (beyond -40°C to 85°C for standard boards), and chemicals can degrade components and traces over time.

- Operating Stress: High voltage or current beyond the board’s rating, such as running a 3.3V circuit at 5V without proper regulation, can cause overheating and failure.

- Component Selection: Using components with mismatched lifespans, like capacitors rated for only 1,000 hours at high temperatures, can limit the overall board life.

By addressing these factors during the design phase, you can create a foundation for long-lasting PCB electronics that are ready for future mods.

Designing PCB Electronics for Longevity and Upgrades

The first step to building PCBs that last and support mods is a robust design. Here are practical tips to ensure your boards are both durable and adaptable for electronics circuit upgrades.

1. Choose High-Quality Materials

Start with a reliable substrate material. FR-4 is a common choice for its balance of cost and durability, with a thermal resistance up to 130°C. For harsher environments, consider polyimide boards, which can withstand temperatures up to 260°C. Opt for thicker copper layers (e.g., 2 oz or 3 oz) if your design involves high current, as this reduces resistance and heat buildup—key to extending PCB electronics lifespan.

2. Plan for Modularity

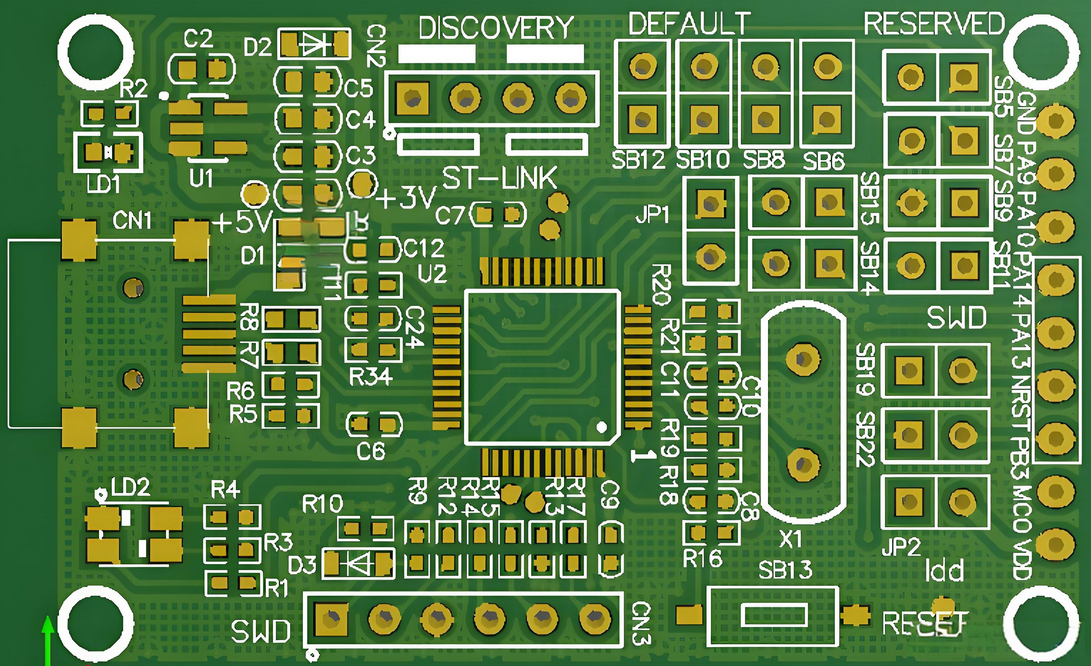

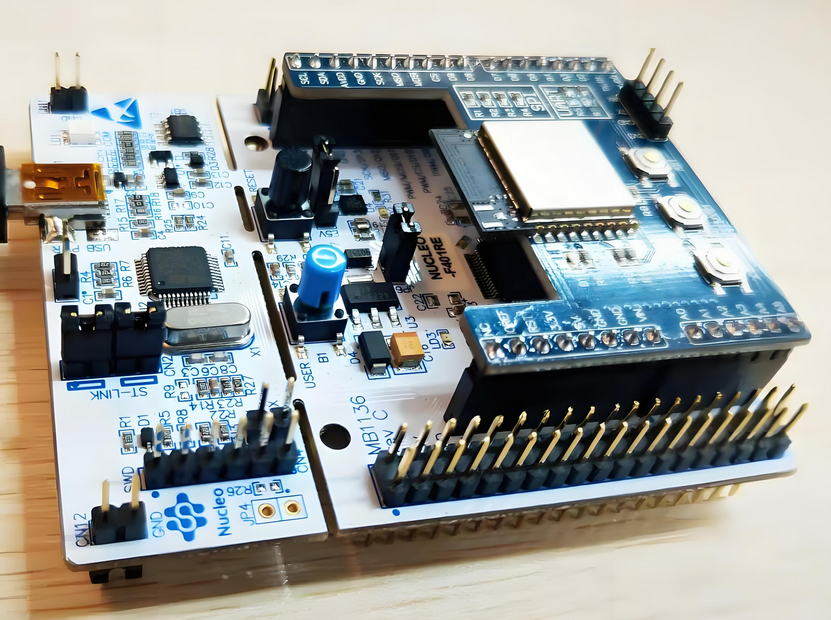

Design your PCB with modularity in mind. Use headers, connectors, or sockets for components that might need replacement or upgrades, such as microcontrollers or sensors. For instance, instead of soldering a microcontroller directly to the board, use a DIP socket or pin headers. This allows you to swap out a 16 MHz processor for a 32 MHz one in the future without desoldering.

3. Optimize Trace Layout

Ensure your traces are wide enough to handle current without overheating. A general rule is to use a trace width of at least 0.010 inches per ampere of current. For a 5A circuit, aim for a 0.050-inch trace width on a 1 oz copper layer to minimize voltage drop and heat. Use design software to simulate impedance and signal integrity, keeping high-speed signals (above 100 MHz) away from noisy power lines to prevent interference.

4. Incorporate Protection Features

Add protection circuits to shield against overvoltage, overcurrent, and electrostatic discharge (ESD). For example, include a transient voltage suppressor (TVS) diode rated for 5V to protect a microcontroller input from spikes up to 30V. These small additions can significantly extend the lifespan of your PCB electronics by preventing sudden failures.

Effective Mods for PCB Electronics Upgrades

Effective Mods for PCB Electronics Upgrades

Mods are custom changes or additions to a PCB that enhance performance or adapt it to new requirements. When done right, mods can breathe new life into existing boards without the need for a full redesign. Here are some proven mods for electronics circuit upgrades.

1. Upgrade Key Components

Replace outdated or underperforming components with modern alternatives. For example, swap an old 8-bit microcontroller with a 32-bit ARM-based chip for better processing power and lower power consumption (e.g., reducing draw from 50 mA to 10 mA at 3.3V). Ensure the new component matches the board’s voltage and pinout or use adapter boards if needed.

2. Add Expansion Modules

If your original design included headers or connectors, you can attach expansion modules for new functionality. For instance, add a Wi-Fi module to a control board by connecting it via SPI or I2C pins, instantly upgrading a standalone device to an IoT-enabled one. This mod avoids soldering directly onto the PCB, preserving its integrity.

3. Improve Power Efficiency

Modify the power supply section to reduce heat and energy loss. Replace linear regulators with switching regulators for better efficiency—converting a 12V input to 5V output with 90% efficiency instead of 40%. This reduces thermal stress on the board, a critical factor in extending PCB electronics lifespan.

4. Enhance Cooling with Mods

For high-power applications, add heat sinks or thermal vias to dissipate heat from components like power transistors or voltage regulators. If a component generates 2W of heat, ensure thermal vias connect to a copper plane with at least 1 square inch of area to spread the heat, keeping temperatures below 85°C for optimal longevity.

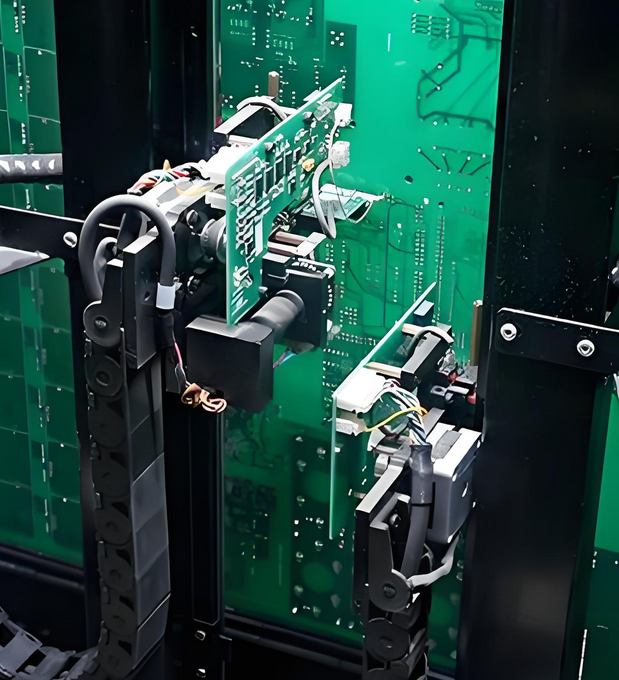

Electronics Manufacturing Tips for Durable PCBs

The manufacturing process plays a huge role in creating PCBs that last and support future mods. Here are essential tips to follow during electronics manufacturing to ensure quality and adaptability.

1. Use Reliable Assembly Techniques

Opt for automated assembly with precise soldering to avoid weak joints that could fail over time. Ensure solder paste is applied evenly, with a stencil thickness of 0.004 to 0.006 inches for surface-mount components, to prevent shorts or insufficient connections. Hand-soldering should be minimized for critical projects to maintain consistency.

2. Apply Protective Coatings

After assembly, apply a conformal coating to shield the PCB from moisture, dust, and chemicals. A thin layer (0.002 inches) of silicone or acrylic coating can protect against humidity levels up to 95%, significantly extending PCB electronics lifespan in harsh environments.

3. Test Thoroughly Before Deployment

Conduct in-circuit testing (ICT) and functional testing to catch defects early. Test for signal integrity at high frequencies (e.g., ensuring a 100 MHz signal has less than 5% jitter) and power stability under load (e.g., no more than 0.1V ripple on a 5V line). Early detection of issues prevents premature failures in the field.

4. Document for Future Mods

Maintain detailed schematics and board layouts with notes on areas designed for upgrades. Label connectors, test points, and unused pads clearly so future mods can be implemented without guesswork. This documentation is invaluable for long-term maintenance and electronics circuit upgrades.

Best Practices for Extending PCB Electronics Lifespan

Beyond design and manufacturing, how you handle and maintain your PCBs after deployment impacts their longevity. Follow these practices to maximize durability.

- Control Operating Conditions: Keep PCBs in environments within their rated temperature range (typically -40°C to 85°C for standard designs) and below 85% humidity to prevent corrosion.

- Regular Maintenance: Inspect boards periodically for dust buildup or component wear. Clean with isopropyl alcohol (90% or higher) and a soft brush to remove contaminants without damaging traces.

- Avoid Overloading: Operate within the board’s current and voltage limits. For a board rated at 3A, keep sustained current below 2.5A to avoid thermal stress.

- Store Properly: If not in use, store PCBs in anti-static bags in a dry, cool place to prevent moisture damage and ESD risks.

Conclusion: Build with the Future in Mind

Creating long-lasting PCB electronics with mods is a powerful way to ensure your designs remain relevant and functional for years. By focusing on durable materials, modular designs, and strategic upgrades, you can extend PCB electronics lifespan while keeping up with technological advancements. From optimizing trace layouts to applying protective coatings during electronics manufacturing, every step counts toward building a board that lasts.

Start with a strong foundation, plan for future electronics circuit upgrades, and maintain your PCBs with care. With these strategies, you’re not just building a board—you’re crafting a solution that evolves. Let this guide be your roadmap to designing PCB electronics that you can build once and upgrade forever.

ALLPCB

ALLPCB