In the fast-evolving world of electronics, Surface Mount Device (SMD) technology continues to play a critical role in shaping the future of design and manufacturing. As the demand for smaller, faster, and more efficient devices grows, the future of SMD technology is brimming with exciting innovations and emerging applications. From advanced SMD components to miniaturization trends, this blog dives deep into the latest developments in Surface Mount Technology (SMT) and how they are driving innovations in electronics. Whether you're an engineer, designer, or tech enthusiast, this guide will help you stay ahead of the curve with actionable insights into the evolving landscape of SMD technology.

What Is SMD Technology and Why Does It Matter?

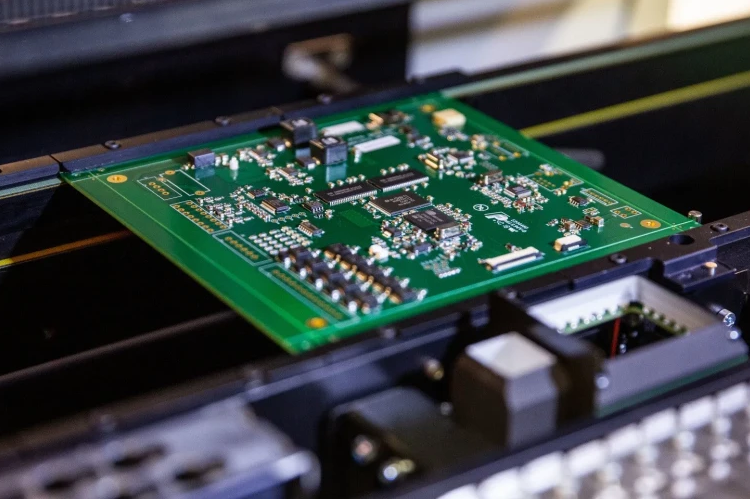

SMD technology refers to the method of mounting electronic components directly onto the surface of a printed circuit board (PCB) rather than inserting them through holes, as in traditional through-hole technology. This approach allows for smaller, lighter, and more densely packed circuits, making it a cornerstone of modern electronics. From smartphones to medical devices, SMD components are everywhere, enabling the compact designs we rely on daily.

The importance of SMD technology lies in its ability to support the ongoing push for miniaturization and efficiency. As industries demand devices with higher performance in smaller packages, innovations in SMD components and SMT processes are vital to meeting these needs. In this blog, we'll explore the future trends shaping this field, including cutting-edge advancements and new applications that are redefining electronics.

Miniaturization Trends: Pushing the Boundaries of Size

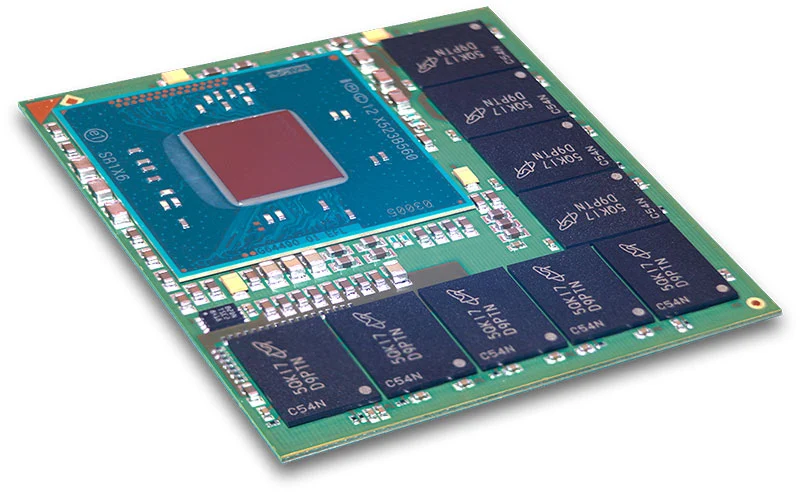

One of the most significant drivers in the future of SMD technology is miniaturization. The trend toward smaller devices is not new, but recent advancements are taking it to new levels. Components are shrinking in size while maintaining or even improving their performance. For instance, chip resistors and capacitors are now available in packages as small as 0201 (0.6mm x 0.3mm), allowing designers to pack more functionality into limited space.

This push for smaller components is fueled by industries like wearables, IoT (Internet of Things), and medical electronics. Wearable devices, such as fitness trackers, require tiny components to fit into sleek, lightweight designs. Similarly, IoT devices often need to operate in constrained environments, where every millimeter of space counts. In medical applications, miniaturized SMD components enable implantable devices like pacemakers, which must be small enough to fit inside the human body without compromising functionality.

Looking ahead, the industry is moving toward even smaller packages, such as 01005 (0.4mm x 0.2mm), though challenges remain in terms of manufacturing precision and thermal management. Advanced SMT equipment is evolving to handle these tiny components with greater accuracy, ensuring reliable assembly even at microscopic scales. According to recent industry reports, the global SMT equipment market is projected to grow at a compound annual growth rate (CAGR) of around 5.9% through 2031, driven by the rising demand for miniaturized electronics.

Advanced SMD Components: Powering Next-Gen Electronics

The development of advanced SMD components is another key trend shaping the future of this technology. These components are designed to meet the demands of high-speed, high-power, and high-frequency applications. For example, SMD inductors and capacitors are now being engineered to handle higher current ratings and lower equivalent series resistance (ESR), which is critical for power management in devices like 5G smartphones and electric vehicles (EVs).

In high-frequency applications, such as 5G infrastructure and automotive radar systems, SMD components must support signal speeds in the gigahertz range. This requires materials with low dielectric loss and precise impedance matching—often around 50 ohms for RF circuits—to minimize signal degradation. Manufacturers are increasingly using advanced ceramics and low-loss substrates to achieve these performance metrics, ensuring that SMD components can keep up with the demands of next-gen electronics.

Additionally, the rise of System-in-Package (SiP) solutions is transforming how SMD components are used. SiP integrates multiple functions—such as processors, memory, and sensors—into a single compact module. This approach not only saves space but also improves performance by reducing interconnect delays. As SiP adoption grows, particularly in mobile and IoT devices, we can expect to see even more innovative SMD designs tailored for integration and efficiency.

Innovations in Electronics: SMT Processes and Equipment

The future of SMD technology isn't just about the components themselves—it's also about the innovations in electronics manufacturing processes and SMT equipment. Automation and precision are at the forefront of these advancements. Modern SMT assembly lines use high-speed pick-and-place machines capable of placing over 100,000 components per hour with accuracy down to 0.01mm. This level of precision is essential for handling the tiny components driving miniaturization trends.

Another exciting innovation is the use of laser direct structuring (LDS) for creating conductive traces directly on 3D surfaces. This technology allows for greater design flexibility, enabling SMD components to be mounted on non-flat surfaces for applications like automotive sensors and wearable tech. Industry forecasts suggest that the market for surface-mountable laser direct structuring will see significant growth by 2032, reflecting its potential to revolutionize SMT design.

Thermal management is also a focus area for SMT innovation. As components become smaller and more powerful, managing heat dissipation is critical to prevent failures. Advanced soldering techniques, such as vapor phase soldering, are being adopted to ensure uniform heat distribution during assembly, reducing the risk of thermal stress on delicate SMD components. These innovations are paving the way for more reliable and durable electronics, even in demanding environments.

Emerging Applications of SMT: Where SMD Technology Is Headed

The emerging applications of SMT are as diverse as they are transformative. As industries adopt SMD technology for new use cases, we’re seeing its impact across various sectors. Here are some of the most promising areas where SMT and advanced SMD components are making a difference:

1. Automotive Electronics

The automotive industry is undergoing a digital revolution, with electric vehicles (EVs) and autonomous driving systems relying heavily on compact, high-performance electronics. SMD components are used in everything from battery management systems to advanced driver-assistance systems (ADAS). For instance, SMD sensors and microcontrollers must withstand harsh conditions like temperature swings from -40°C to 85°C while maintaining reliability. The demand for surface mount fuses, critical for circuit protection in EVs, is expected to drive market growth to USD 2.43 billion by 2032, at a CAGR of 5.12%.

2. Medical Devices

In healthcare, SMD technology is enabling life-saving innovations. Miniaturized components are essential for devices like hearing aids, insulin pumps, and diagnostic tools. These applications often require components with low power consumption and high precision, ensuring accurate readings and long battery life. As telemedicine and remote monitoring grow, SMD technology will play a key role in developing portable, connected medical solutions.

3. 5G and Telecommunications

The rollout of 5G networks is creating a surge in demand for high-frequency SMD components. Base stations, antennas, and user devices all rely on SMT for compact, efficient designs that can handle data rates exceeding 10 Gbps. This trend is pushing manufacturers to develop components with tighter tolerances and improved signal integrity, ensuring seamless connectivity in the 5G era.

4. IoT and Smart Devices

The IoT ecosystem is exploding, with billions of connected devices expected to be in use by the end of the decade. SMD technology is at the heart of these devices, enabling small form factors and low power consumption. From smart home sensors to industrial monitoring systems, emerging applications of SMT are making our world more connected and intelligent.

Challenges and Opportunities in the Future of SMD Technology

While the future of SMD technology is full of promise, it’s not without challenges. One major hurdle is the complexity of assembling ultra-small components. As packages shrink, the risk of defects like solder bridging or misalignment increases, requiring more sophisticated inspection systems like automated optical inspection (AOI) and X-ray imaging.

Another challenge is balancing performance with cost. Advanced SMD components often come with higher price tags, which can be a barrier for mass-market applications. However, as manufacturing technologies improve and economies of scale kick in, costs are expected to decrease, making these innovations more accessible.

On the opportunity side, the growing demand for sustainable electronics is opening new doors for SMD technology. Manufacturers are exploring eco-friendly materials and lead-free soldering processes to meet regulatory standards and consumer expectations. This shift not only benefits the environment but also positions companies as leaders in a socially responsible market.

How to Stay Ahead with SMD Technology Trends

For engineers and designers, staying ahead in the fast-paced world of SMD technology means keeping up with the latest tools and techniques. Collaborating with reliable PCB assembly partners can help streamline the integration of advanced SMD components into your designs. Leveraging simulation software to test layouts and thermal performance before production can also save time and reduce errors.

Additionally, staying informed about industry advancements through webinars, trade shows, and technical journals is a great way to gain insights into miniaturization trends and emerging applications of SMT. By adopting a proactive approach, you can ensure your projects are future-proof and aligned with the cutting-edge innovations in electronics.

Conclusion: The Exciting Road Ahead for SMD Technology

The future of SMD technology is bright, with innovations in advanced components, miniaturization trends, and SMT processes driving progress across industries. From automotive to medical and telecommunications, the emerging applications of SMT are transforming how we design and interact with electronics. As challenges like assembly complexity and cost are addressed through technological advancements, we can expect SMD technology to become even more integral to our connected world.

By understanding these trends and leveraging the latest tools, engineers and designers can create products that are smaller, smarter, and more efficient. At ALLPCB, we’re committed to supporting this journey with high-quality PCB assembly services tailored to the evolving needs of SMD technology. Let’s build the future of electronics together, one tiny component at a time.

ALLPCB

ALLPCB