When designing printed circuit boards (PCBs) for telecommunications, choosing the right material is critical for performance, reliability, and cost-efficiency. Two popular options often come into focus: FR-4, a widely used standard material, and high-speed laminates, which are tailored for demanding applications. So, which one should you choose for your telecommunications project? In short, FR-4 is a cost-effective choice for lower-frequency applications, while high-speed laminates excel in high-frequency, low-loss environments due to their superior dielectric properties and reduced signal loss.

In this comprehensive guide, we’ll dive deep into the world of PCB materials for telecommunications, comparing FR-4 vs. high-speed laminates to help you make an informed decision. Whether you're working on 5G infrastructure, satellite systems, or high-speed data networks, understanding factors like dielectric constant in PCBs and signal loss in PCB materials is essential. Let’s explore the differences, benefits, and applications of these materials to ensure your next project meets its performance goals.

Why PCB Material Matters in Telecommunications

Telecommunications systems, such as base stations, routers, and fiber-optic networks, rely on PCBs to transmit signals with minimal distortion and loss. The material used in a PCB directly impacts how well it handles high-frequency signals, manages heat, and maintains signal integrity. Poor material choices can lead to signal degradation, increased noise, or even system failure—issues that are unacceptable in critical telecom applications.

Two key properties to consider when selecting a PCB material are the dielectric constant (Dk) and the dissipation factor (Df), which influence signal speed and loss. Materials with a lower Dk allow signals to travel faster, while a lower Df reduces signal loss, making them ideal for high-speed designs. Let’s see how FR-4 and high-speed laminates stack up in these areas.

Understanding FR-4: The Industry Standard for PCBs

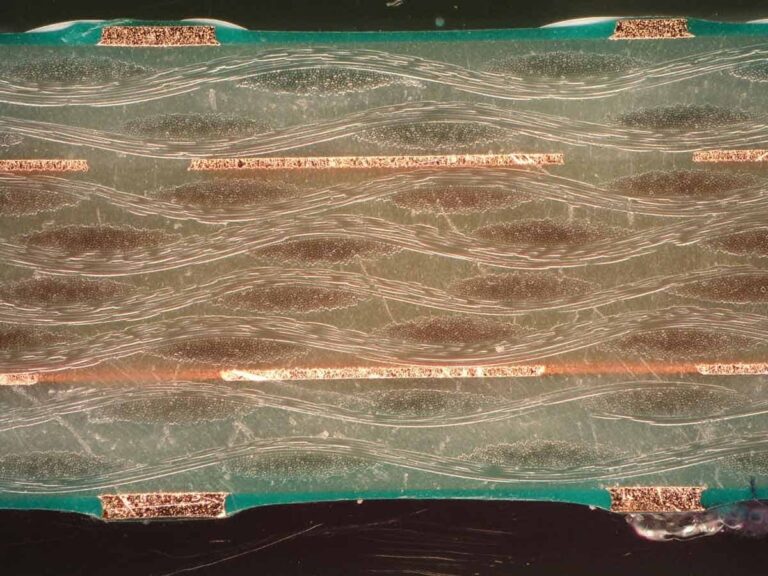

FR-4 is the most common PCB material, widely used across industries due to its affordability and versatility. Made from woven fiberglass and epoxy resin, FR-4 stands for "Flame Retardant 4," indicating its resistance to fire—a crucial safety feature for electronic devices.

Key Properties of FR-4

- Dielectric Constant (Dk): Typically ranges from 4.2 to 4.7 at 1 MHz, depending on the specific formulation and frequency. This relatively high Dk slows down signal propagation, making FR-4 less ideal for very high-frequency applications.

- Dissipation Factor (Df): Around 0.02 at 1 MHz, which indicates moderate signal loss. This can become problematic at frequencies above 1 GHz, common in modern telecom systems.

- Thermal Stability: FR-4 has a glass transition temperature (Tg) of about 130°C to 140°C in standard versions, though high-Tg variants can reach up to 170°C for better heat resistance.

- Cost: Extremely cost-effective, often priced at a fraction of high-speed laminates, making it a go-to for budget-conscious projects.

Advantages of FR-4 in Telecommunications

FR-4 shines in telecommunications applications that don’t require extremely high frequencies or ultra-low signal loss. For example, it’s often used in control boards or less demanding parts of telecom equipment where cost savings are a priority. Its mechanical strength and ease of manufacturing also make it a reliable choice for simpler designs.

Limitations of FR-4

However, FR-4 struggles in high-frequency environments. At frequencies above 1 GHz, signal loss becomes significant due to its higher dissipation factor. Additionally, its dielectric constant can vary with frequency and temperature, leading to impedance mismatches in high-speed designs. For 5G or other cutting-edge telecom systems operating at frequencies of 3 GHz or higher, FR-4 often falls short.

High-Speed Laminates: Built for Performance

High-speed laminates are advanced materials engineered for applications where signal integrity and low loss are non-negotiable. These materials are often used in telecommunications for high-frequency circuits, such as 5G antennas, microwave systems, and satellite communications.

Key Properties of High-Speed Laminates

- Dielectric Constant (Dk): Typically much lower than FR-4, ranging from 2.2 to 3.5. This allows signals to travel faster, making these materials ideal for high-frequency applications.

- Dissipation Factor (Df): Often as low as 0.001 to 0.003, significantly reducing signal loss compared to FR-4. This is critical for maintaining signal integrity over long distances or at high frequencies.

- Thermal Stability: Many high-speed laminates offer excellent thermal performance, with Tg values often exceeding 200°C, ensuring reliability in harsh environments.

- Cost: These materials are more expensive, sometimes costing 5 to 10 times more than FR-4, due to their specialized composition and manufacturing processes.

Advantages of High-Speed Laminates in Telecommunications

High-speed laminates are the preferred choice for modern telecom systems that operate at frequencies above 1 GHz. Their low dielectric constant in PCBs and minimal signal loss in PCB materials ensure clean signal transmission, which is vital for applications like 5G networks where data rates can exceed 10 Gbps. They also provide consistent performance across a wide range of frequencies and temperatures, reducing the risk of impedance issues.

Limitations of High-Speed Laminates

The primary drawback of high-speed laminates is their cost, which can be prohibitive for projects with tight budgets. Additionally, they may require specialized manufacturing techniques, such as tighter control over layer alignment and impedance, which can increase production complexity.

FR-4 vs. High-Speed Laminates: A Head-to-Head Comparison

Let’s break down the differences between FR-4 and high-speed laminates across key factors relevant to telecommunications design.

| Property | FR-4 | High-Speed Laminates |

|---|---|---|

| Dielectric Constant (Dk) | 4.2 - 4.7 | 2.2 - 3.5 |

| Dissipation Factor (Df) | ~0.02 | 0.001 - 0.003 |

| Frequency Range | Up to 1 GHz (with limitations) | 1 GHz and above (optimal) |

| Cost | Low | High |

| Thermal Stability (Tg) | 130°C - 170°C | 200°C and above |

| Applications | Low to mid-frequency telecom | High-frequency, 5G, satellite |

From this comparison, it’s clear that high-speed laminates outperform FR-4 in terms of signal integrity and frequency handling, making them the better choice for advanced telecommunications systems. However, FR-4 remains a practical option for less demanding applications where cost is a major concern.

Applications in Telecommunications: When to Use Each Material

Choosing between FR-4 and high-speed laminates depends on the specific requirements of your telecommunications project. Here are some scenarios to guide your decision:

When to Use FR-4

- Low-Frequency Systems: For telecom equipment operating below 1 GHz, such as traditional voice communication systems or basic control boards, FR-4 provides sufficient performance at a lower cost.

- Cost-Sensitive Projects: If budget constraints are a priority and signal integrity at high frequencies isn’t critical, FR-4 is a reliable choice.

- Prototyping: During the early stages of design, FR-4 can be used for prototypes before transitioning to high-speed materials for final production.

When to Use High-Speed Laminates

- 5G and Beyond: High-speed laminates are essential for 5G infrastructure, where frequencies often range from 3 GHz to 30 GHz or higher. Their low signal loss in PCB material ensures data is transmitted without degradation.

- Satellite and Microwave Systems: These applications require materials that can handle extreme frequencies and environmental conditions, making high-speed laminates the ideal choice.

- High Data Rates: For telecom systems transmitting data at rates above 10 Gbps, high-speed laminates maintain signal integrity over long distances.

Factors to Consider When Choosing PCB Materials for Telecommunications

Beyond just material properties, several other factors play a role in selecting the right PCB material for your telecom project. Here are some key considerations:

- Frequency Requirements: Determine the operating frequency of your system. If it’s above 1 GHz, high-speed laminates are likely necessary.

- Signal Integrity Needs: Assess how critical signal clarity is for your application. High-speed designs often require minimal noise and loss, favoring advanced materials.

- Budget Constraints: Balance performance with cost. If high-speed laminates are overkill for your application, FR-4 can save significant expenses.

- Environmental Conditions: Consider temperature, humidity, and other factors. High-speed laminates often offer better stability in harsh conditions.

- Manufacturing Capabilities: Ensure your production process can handle the material. High-speed laminates may require specialized equipment or tighter tolerances.

Optimizing Designs with Hybrid Approaches

In some cases, you don’t have to choose between FR-4 and high-speed laminates exclusively. Hybrid PCBs combine both materials in a single board, using high-speed laminates for critical high-frequency layers and FR-4 for less demanding sections. This approach offers a balance of performance and cost, making it a popular choice for complex telecom systems.

For example, in a 5G base station PCB, the layers handling high-frequency signals might use a low-Dk laminate, while power and control layers use FR-4 to keep costs down. This hybrid strategy can reduce overall expenses while still meeting performance requirements.

Conclusion: Making the Right Choice for Your Telecom PCB

Selecting the best PCB material for telecommunications comes down to understanding your project’s specific needs. FR-4 offers a budget-friendly solution for low to mid-frequency applications, while high-speed PCB materials like advanced laminates are indispensable for cutting-edge systems requiring minimal signal loss in PCB material and a low dielectric constant in PCBs.

By carefully evaluating factors like frequency, signal integrity, and budget, you can choose the material—or combination of materials—that ensures optimal performance and reliability. Whether you’re designing for 5G networks, satellite systems, or traditional telecom equipment, the right material lays the foundation for success.

At ALLPCB, we’re committed to helping you navigate these choices with expert guidance and high-quality manufacturing solutions. Explore our range of material options and design support to bring your telecommunications projects to life with confidence.

ALLPCB

ALLPCB