In the fast-evolving world of automated teller machines (ATMs), efficient power management is key to ensuring reliability, reducing costs, and enhancing user experience. How can we optimize ATM PCB power consumption and design for sustainability? The answer lies in strategic power management techniques for printed circuit boards (PCBs), including the use of advanced DC-DC converter ATM PCB designs, maintaining power integrity PCB design, adopting low power ATM design principles, and implementing effective power plane design ATM layouts. In this comprehensive guide, we’ll explore these strategies in detail, offering practical insights for engineers and designers looking to build the next generation of energy-efficient ATMs.

Why Power Management Matters for ATM PCBs

ATMs are critical financial tools that operate 24/7, often in remote or high-traffic locations. This constant operation demands a robust power management system to prevent downtime, reduce energy waste, and extend the lifespan of components. Poor power management on PCBs can lead to overheating, voltage drops, and system failures, which directly impact customer trust and operational costs. By focusing on efficient power strategies, designers can address ATM PCB power consumption challenges and ensure machines run smoothly under varying conditions.

Beyond reliability, energy efficiency is becoming a priority as organizations aim to meet sustainability goals. Reducing power usage not only lowers electricity bills but also minimizes the environmental footprint of ATM networks. Let’s dive into the core strategies for achieving these goals through smart PCB design.

Understanding ATM PCB Power Consumption Challenges

ATMs are complex systems with multiple components—displays, card readers, cash dispensers, and communication modules—all drawing power from the PCB. High ATM PCB power consumption often results from inefficient voltage regulation, parasitic losses, and suboptimal component selection. For instance, a typical ATM might consume between 100 to 300 watts during operation, with significant spikes during cash dispensing or data transmission. Without proper management, this can strain the power supply and lead to thermal issues.

Another challenge is the need to support a wide input voltage range, often between 12V and 48V, depending on the machine’s location and power source. Fluctuations in input voltage can cause instability in the system if the PCB isn’t designed to handle them. Addressing these issues starts with a focus on efficient power conversion and distribution, which we’ll explore next.

Leveraging DC-DC Converters for ATM PCB Efficiency

A critical component in managing ATM PCB power consumption is the DC-DC converter ATM PCB design. DC-DC converters step down or step up voltage levels to match the needs of different ATM components, ensuring stable power delivery. For example, while the main power supply might provide 24V, sensitive microcontrollers may require only 3.3V or 5V. A well-designed DC-DC converter minimizes energy loss during this conversion process.

Modern DC-DC converters, such as synchronous buck converters, can achieve efficiencies above 90%, compared to older linear regulators that often waste 30-50% of input power as heat. By integrating high-efficiency converters into the PCB, designers can significantly reduce overall power draw. Additionally, selecting converters with low quiescent current (often below 100 μA) helps minimize standby power consumption when the ATM is idle.

For practical implementation, ensure the DC-DC converter is placed close to the load to reduce trace resistance and inductance, which can cause voltage drops. Also, use appropriate filtering capacitors (e.g., 10 μF to 100 μF depending on the load) to smooth out ripple voltages, typically keeping them below 50 mV for sensitive components.

Ensuring Power Integrity in PCB Design

Maintaining power integrity PCB design is essential for reliable ATM operation. Power integrity refers to the ability of the PCB to deliver stable voltage and current to all components without noise or interference. Poor power integrity can lead to voltage sags, electromagnetic interference (EMI), and erratic behavior in high-speed circuits like those used for data processing in ATMs.

One key aspect of power integrity is minimizing impedance in the power delivery network (PDN). A high-impedance PDN can cause significant voltage drops during sudden current demands, such as when a cash dispenser motor starts. To address this, designers should aim for a PDN target impedance of less than 1 mΩ for high-current paths, achieved through wide power traces and multiple vias connecting power planes.

Decoupling capacitors also play a vital role in power integrity. Placing small-value capacitors (e.g., 0.1 μF) near IC power pins helps suppress high-frequency noise, while larger bulk capacitors (e.g., 10 μF to 47 μF) near the power entry point stabilize voltage during transients. Simulation tools can help analyze PDN performance, ensuring noise levels remain below 1% of the supply voltage (e.g., 50 mV for a 5V rail).

Adopting Low Power ATM Design Principles

Creating a low power ATM design starts with selecting energy-efficient components and implementing smart power-saving modes. For instance, using low-power microcontrollers and sensors can reduce baseline consumption by 20-30%. Many modern processors support sleep or deep-sleep modes, where power draw drops to microampere levels during idle periods. Enabling these modes in ATMs can cut standby power by up to 50%.

Another strategy is to optimize peripheral usage. Displays, for example, are significant power hogs in ATMs, often consuming 10-20 watts. Switching to LED-backlit or OLED screens can lower this by 30%, while dimming the display during inactivity saves even more. Similarly, powering down non-essential modules like card readers when not in use can further reduce overall draw.

Software optimization also plays a role in low power ATM design. Firmware can be programmed to dynamically adjust power states based on user activity, ensuring the system operates at minimal power during quiet hours. Combining these hardware and software approaches creates a holistic solution for energy efficiency.

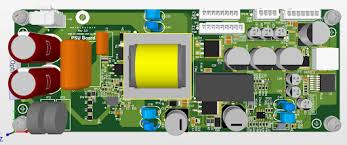

Optimizing Power Plane Design for ATMs

The power plane design ATM layout is a foundational element of efficient power management. Power planes are large copper areas on a PCB dedicated to distributing voltage across the board. A well-designed power plane minimizes resistance and inductance, ensuring uniform voltage delivery even under high current loads.

For ATMs, where current demands can spike to 5-10A during operations like cash dispensing, a solid power plane is critical. Splitting the plane into separate sections for different voltage levels (e.g., 5V for logic, 12V for motors) prevents noise from one domain affecting another. However, ensure adequate spacing (at least 20 mils) between planes to avoid crosstalk or capacitance issues.

Stack-up design also impacts power plane performance. In a typical 4-layer PCB, dedicate the inner layers to power and ground planes, sandwiching them between signal layers. This configuration reduces EMI and provides a low-impedance return path for signals. For high-current areas, increase copper thickness to 2 oz or more to handle loads without excessive heating—keeping temperature rises below 10°C per watt of dissipation.

Thermal Management in Power-Efficient ATM PCBs

Efficient power management isn’t just about reducing consumption; it’s also about managing the heat generated by power dissipation. High ATM PCB power consumption often leads to elevated temperatures, which can degrade components and reduce system lifespan. For instance, every 10°C increase in operating temperature can halve the life of electrolytic capacitors commonly used in power circuits.

To mitigate this, incorporate thermal vias under high-power components like DC-DC converters to transfer heat to the opposite side of the board or to a heatsink. Use copper pours as heat spreaders around hot spots, ensuring they cover at least 2-3 times the area of the component footprint. Additionally, select components with low thermal resistance (e.g., MOSFETs with Rth(j-a) below 40°C/W) to minimize heat buildup.

Proper airflow within the ATM enclosure is also crucial. Ensure PCB layouts allow for unobstructed air paths, and consider adding small fans if passive cooling isn’t sufficient. Keeping junction temperatures below 85°C for most ICs ensures long-term reliability.

Future Trends in ATM Power Management

As technology advances, so do the opportunities for improving power efficiency in ATMs. Emerging trends include the adoption of wide-bandgap semiconductors like GaN and SiC in DC-DC converter ATM PCB designs. These materials enable higher switching frequencies (up to 1 MHz), reducing the size of inductors and capacitors while boosting efficiency to over 95%.

Another trend is the integration of smart power monitoring on PCBs. Sensors embedded in the board can track ATM PCB power consumption in real-time, providing data for predictive maintenance and dynamic power adjustments. This is particularly useful for remote ATMs, where minimizing downtime is critical.

Finally, the push for renewable energy integration means future ATMs may incorporate solar or battery backup systems. PCB designs will need to accommodate these alternative power sources, requiring flexible input voltage handling and efficient energy storage solutions.

Conclusion: Building Energy-Efficient ATMs with Smart PCB Design

Power management is at the heart of creating reliable, sustainable, and cost-effective ATMs. By focusing on strategies like optimizing ATM PCB power consumption, integrating high-efficiency DC-DC converter ATM PCB solutions, ensuring power integrity PCB design, adopting low power ATM design practices, and refining power plane design ATM layouts, engineers can build systems that meet modern demands. These techniques not only improve performance but also contribute to a greener future by reducing energy waste.

Implementing these strategies requires careful planning, from component selection to layout optimization, but the payoff is worth it—longer-lasting machines, lower operating costs, and satisfied users. As technology continues to evolve, staying ahead of power management trends will ensure ATMs remain a trusted part of our financial infrastructure for years to come.