When deciding on the best surface finish for your printed circuit board (PCB), the choice often comes down to Immersion Silver and Electroless Nickel Immersion Gold (ENIG). Both are popular options in the industry, but which one is right for your project? In short, Immersion Silver is often a cost-effective choice with excellent performance for many applications, while ENIG offers superior reliability and durability, especially for demanding environments. In this detailed guide, we’ll break down the differences between Immersion Silver vs ENIG, comparing cost, performance, reliability, and specific advantages to help you make an informed decision for your PCB needs.

Understanding PCB Surface Finishes: Why They Matter

A PCB surface finish is a critical layer applied to the copper traces of a board to protect them from oxidation, ensure solderability, and enhance overall performance. The right finish can impact the longevity, reliability, and functionality of your PCB, especially in applications ranging from consumer electronics to industrial systems. Two of the most widely used finishes are Immersion Silver and ENIG, each with unique properties that suit different needs.

What is Immersion Silver?

Immersion Silver is a surface finish applied through a chemical process where a thin layer of silver (typically 0.1 to 0.3 micrometers thick) is deposited onto the copper traces of a PCB. This finish is known for its excellent conductivity and flat surface, making it ideal for high-speed signal applications and fine-pitch components. It’s often chosen for its balance of cost and performance, particularly in lead-free soldering processes.

What is ENIG?

ENIG, or Electroless Nickel Immersion Gold, is a two-layer surface finish consisting of a nickel base layer (4 to 7 micrometers thick) topped with a thin gold layer (0.05 to 0.1 micrometers thick). The nickel acts as a barrier to protect the copper, while the gold prevents oxidation and ensures excellent solderability. ENIG is widely used in applications requiring high reliability, such as medical devices and aerospace systems, due to its durability and resistance to wear.

Immersion Silver vs ENIG: A Detailed Comparison

To help you decide between these two finishes, let’s compare them across key factors: cost, performance, reliability, and specific advantages. This breakdown will give you a clear picture of how each finish performs in real-world applications.

1. ENIG vs Immersion Silver Cost

Cost is often a deciding factor when choosing a PCB surface finish, especially for large-scale production. Here’s how Immersion Silver and ENIG stack up:

- Immersion Silver: This finish is generally more affordable than ENIG. The process involves fewer steps and materials, resulting in a lower cost per board. For projects with tight budgets or high-volume runs, Immersion Silver can save significant expenses, often being 20-30% cheaper than ENIG depending on the manufacturer and board specifications.

- ENIG: ENIG is more expensive due to the dual-layer process involving both nickel and gold. The materials and additional processing steps increase the cost, making it less ideal for budget-conscious projects. However, the higher upfront cost can be justified by its long-term reliability in critical applications.

Key Takeaway: If cost is your primary concern, Immersion Silver is the better choice. For projects where reliability outweighs budget constraints, ENIG may be worth the investment.

2. ENIG vs Immersion Silver Performance

Performance is crucial, especially for PCBs used in high-speed or high-frequency applications. Let’s examine how these finishes impact signal integrity and solderability:

- Immersion Silver: This finish offers excellent electrical conductivity due to the silver layer, which has a lower resistance compared to other finishes. It’s particularly beneficial for high-frequency applications where signal integrity is critical, often supporting signal speeds with minimal loss (e.g., impedance values can be maintained within tight tolerances of ±10% for high-speed designs). Additionally, its flat surface is ideal for fine-pitch components and ball grid arrays (BGAs), ensuring precise soldering.

- ENIG: ENIG also performs well in terms of solderability, thanks to the gold layer that prevents oxidation. However, the nickel underlayer can slightly impact signal integrity in ultra-high-frequency applications due to its higher resistance compared to silver. For most standard applications, this difference is negligible, but in specialized designs requiring minimal signal loss, Immersion Silver might have an edge.

Key Takeaway: Immersion Silver generally outperforms ENIG in high-speed signal applications due to better conductivity. ENIG, however, offers consistent solderability across a wide range of conditions.

3. ENIG vs Immersion Silver Reliability

Reliability is a critical factor for PCBs that must operate in harsh environments or over extended periods. Here’s how these finishes compare:

- Immersion Silver: While Immersion Silver provides good protection against oxidation initially, it is prone to tarnishing over time, especially in high-humidity or sulfur-rich environments. This tarnishing can affect solderability if the PCB is stored for long periods before assembly. Additionally, it’s less resistant to wear from multiple soldering cycles, with potential degradation after 2-3 reflows.

- ENIG: ENIG is far more reliable in challenging conditions. The nickel layer acts as a robust barrier against corrosion, and the gold topcoat resists tarnishing, ensuring long-term solderability even after prolonged storage. ENIG can withstand multiple reflow cycles (often up to 5 or more) without significant degradation, making it ideal for complex assemblies or rework-heavy processes.

Key Takeaway: ENIG is the clear winner for reliability, especially in demanding or long-term applications. Immersion Silver is better suited for projects with shorter shelf life or less harsh operating conditions.

4. Immersion Silver Advantages Over ENIG

While ENIG excels in reliability, Immersion Silver has distinct advantages that make it a preferred choice in specific scenarios. Here are the key benefits:

- Lower Cost: As mentioned earlier, Immersion Silver is more budget-friendly, making it ideal for cost-sensitive projects or high-volume production runs.

- Better Signal Performance: Its superior conductivity makes it a top choice for high-frequency and high-speed designs where maintaining signal integrity is paramount.

- Flat Surface for Fine-Pitch Components: The uniform, flat finish of Immersion Silver supports precise placement and soldering of small components, reducing defects in densely packed boards.

- Environmentally Friendly Process: Compared to some other finishes, the Immersion Silver process involves fewer hazardous chemicals, aligning with eco-conscious manufacturing practices.

Key Takeaway: Immersion Silver offers cost savings and performance benefits, particularly for high-speed designs and fine-pitch assemblies, making it a strong contender in many applications.

Application-Specific Recommendations

Choosing between Immersion Silver and ENIG often depends on the specific requirements of your project. Here are some tailored recommendations based on common use cases:

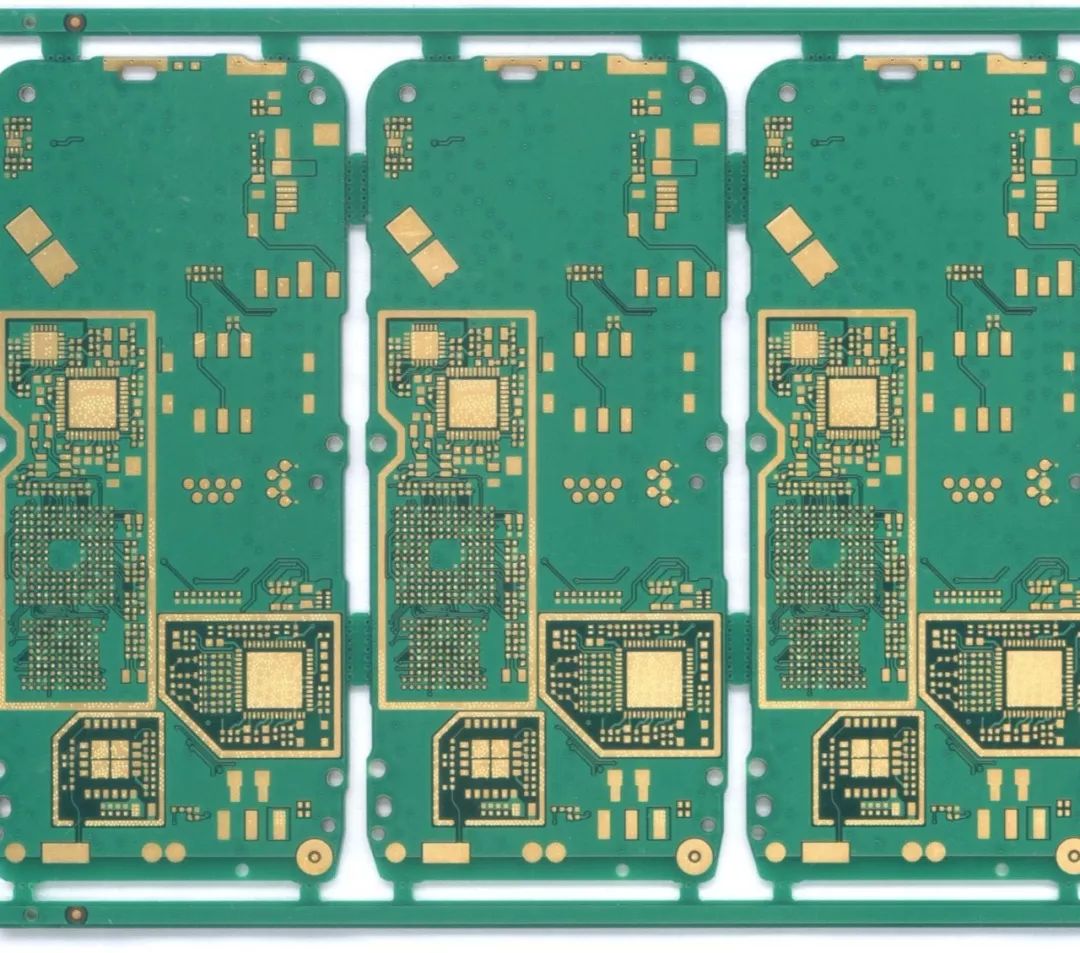

- Consumer Electronics: For products like smartphones or gaming devices with high-speed signals and cost constraints, Immersion Silver is often the better choice due to its performance and affordability.

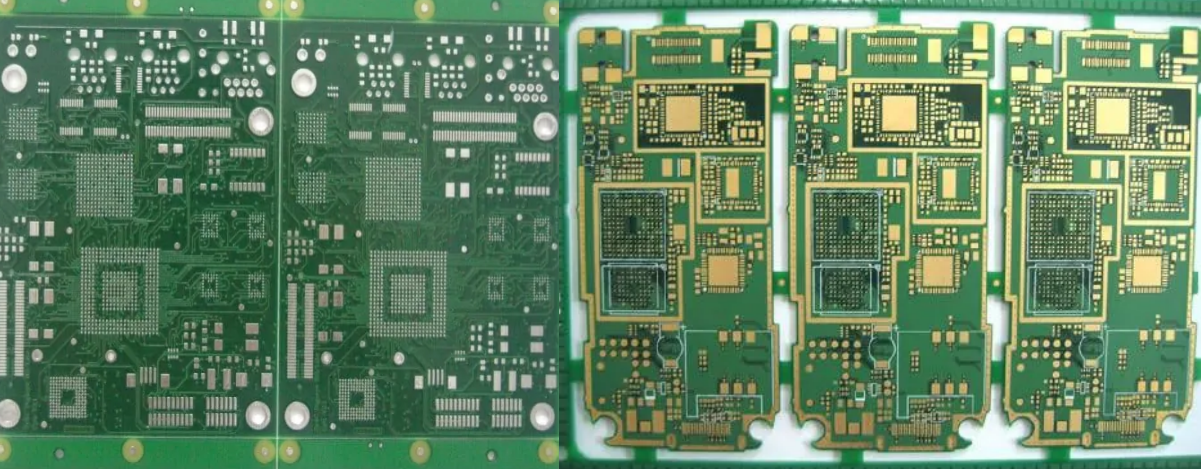

- Industrial and Automotive: In environments with temperature fluctuations and humidity, ENIG’s reliability and resistance to corrosion make it the preferred option.

- Medical and Aerospace: For mission-critical applications where failure is not an option, ENIG’s durability and ability to withstand multiple reflows ensure consistent performance.

- Prototyping: If you’re in the early stages of design and cost is a concern, Immersion Silver can be a practical choice for initial runs before switching to ENIG for production.

Potential Drawbacks to Consider

No surface finish is perfect, and both Immersion Silver and ENIG have limitations to keep in mind:

- Immersion Silver: Its susceptibility to tarnishing means it’s not ideal for long-term storage or harsh environments. Special packaging or quick assembly timelines may be necessary to maintain its effectiveness.

- ENIG: The higher cost can be prohibitive for large-scale or low-budget projects. Additionally, in rare cases, a phenomenon known as “black pad” (a defect in the nickel layer) can occur, though modern manufacturing techniques have largely mitigated this issue.

How to Choose the Right Finish for Your PCB

Selecting between Immersion Silver and ENIG requires balancing your project’s priorities. Consider these steps to make an informed decision:

- Define Your Budget: Determine how much you can allocate for surface finish costs, especially for high-volume production.

- Assess Performance Needs: Evaluate whether your design requires high-speed signal integrity or if standard performance is sufficient.

- Consider Environmental Factors: Think about the operating conditions and storage duration of your PCB to ensure the finish can withstand them.

- Plan for Assembly: Factor in the complexity of soldering and the number of reflow cycles your board will undergo.

By weighing these factors, you can narrow down the best option for your specific application.

Conclusion: Making the Best Choice for Your PCB

Deciding between Immersion Silver and ENIG ultimately depends on your project’s unique requirements. Immersion Silver stands out for its cost-effectiveness, excellent signal performance, and suitability for fine-pitch components, making it a great choice for many consumer electronics and high-speed designs. On the other hand, ENIG offers unmatched reliability and durability, ideal for critical applications in harsh environments or with long-term storage needs.

ALLPCB

ALLPCB