In the world of medical technology, personalized solutions are becoming a game-changer. When it comes to hearing aids, how can custom PCB design address individual patient needs? The answer lies in creating patient-specific PCBs that cater to unique hearing profiles, lifestyle preferences, and physical requirements through tailored design variations. At ALLPCB, we understand the importance of precision and personalization in crafting circuit boards for hearing aids that truly make a difference.

In this blog, we’ll dive deep into the role of custom PCB design in personalized hearing aids. We’ll explore why patient-specific PCBs are critical, how design variations meet individual needs, and the technical aspects that ensure high performance in these life-changing devices. Whether you're an engineer, a medical device developer, or simply curious about the technology behind hearing aids, this guide will provide valuable insights into the intersection of PCB innovation and personalized healthcare.

Why Personalized Hearing Aids Matter

Hearing loss is not a one-size-fits-all condition. Each person experiences it differently, with variations in the degree of loss, frequency ranges affected, and even personal preferences for sound amplification. Traditional hearing aids often follow a generic design, which may not fully address these unique needs. This is where personalized hearing aids come into play, offering a tailored experience that enhances comfort, sound quality, and usability.

Custom PCB design is at the heart of this personalization. By creating patient-specific PCBs, manufacturers can integrate features like adjustable frequency responses, noise reduction algorithms, and even wireless connectivity, all while ensuring the device fits comfortably within the user’s ear. This level of customization not only improves the user’s hearing experience but also boosts their confidence and quality of life.

The Role of Custom PCB Design in Hearing Aids

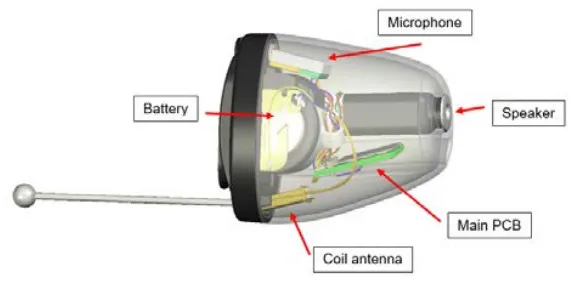

Printed Circuit Boards (PCBs) are the backbone of any electronic device, including hearing aids. They house the components that process sound, manage power, and enable connectivity. In the context of personalized hearing aids, custom PCB design allows for precise control over these functions to match a patient’s specific requirements.

For instance, a patient with high-frequency hearing loss may need a hearing aid that amplifies specific sound ranges. A custom PCB can be designed to support microprocessors and digital signal processing (DSP) chips that prioritize these frequencies. Similarly, for patients sensitive to background noise, the PCB can integrate advanced noise-cancellation circuitry to filter out unwanted sounds.

Moreover, the physical layout of the PCB must often be adapted to fit within tiny, custom-molded hearing aid shells. This requires flexible or rigid-flex PCB designs that can conform to irregular shapes without compromising performance. At ALLPCB, we specialize in crafting such intricate designs to ensure both functionality and comfort.

Key Benefits of Patient-Specific PCBs in Hearing Aids

Designing PCBs with a focus on individual needs offers several advantages. Here are some of the key benefits that make patient-specific PCBs essential for modern hearing aids:

- Enhanced Sound Customization: Patient-specific PCBs allow for fine-tuned sound processing, ensuring that the hearing aid amplifies the right frequencies for each user. For example, a PCB might be programmed to boost sounds between 2,000 and 4,000 Hz, a common range for speech clarity, based on audiogram data.

- Improved Comfort and Fit: Smaller, custom-designed PCBs can fit into compact hearing aid models, reducing bulk and improving wearability for users with specific ear canal shapes.

- Power Efficiency: Hearing aids rely on tiny batteries, so power management is critical. Custom PCBs can optimize power consumption, extending battery life to 5-7 days on a single charge for some devices.

- Advanced Features: Personalized PCBs enable the integration of modern features like Bluetooth connectivity for streaming audio directly from a smartphone, or adaptive algorithms that adjust to different listening environments.

Design Variations for Individual Needs in Hearing Aid PCBs

Every patient has a unique set of needs, and custom PCB design offers the flexibility to create variations that address these differences. Let’s explore some common design variations that cater to individual requirements in hearing aids:

1. Frequency Response Customization

Hearing loss often affects specific frequency ranges. Some patients struggle with low-frequency sounds, while others may have difficulty with high-frequency tones. Custom PCBs can be designed to support amplifiers and filters that target these specific ranges. For example, a PCB might include a bandpass filter with a cutoff frequency of 1,000 Hz to 3,000 Hz to enhance speech sounds for a particular user.

2. Noise Reduction and Feedback Control

Background noise and feedback (whistling sounds) are common challenges for hearing aid users. Patient-specific PCBs can integrate advanced DSP chips that use real-time algorithms to suppress noise and cancel feedback. These chips often operate at signal processing speeds of up to 100 MHz to ensure seamless sound adjustment.

3. Connectivity Options

Many modern hearing aids offer wireless connectivity for streaming audio or connecting to mobile apps for control. Custom PCBs can incorporate low-power Bluetooth modules with impedance values matched to the antenna (typically around 50 ohms) to ensure reliable signal transmission without draining the battery.

4. Size and Shape Adaptations

The physical design of the PCB must match the hearing aid’s form factor, which is often dictated by the patient’s ear anatomy. Flexible PCBs or multi-layer designs can be used to fit into tight spaces, with layer thicknesses as low as 0.1 mm to maintain a slim profile.

Technical Challenges in Designing Custom Hearing Aid PCBs

While the benefits of personalized hearing aids are clear, designing custom PCBs for these devices comes with unique challenges. Here are some of the technical hurdles engineers face and how they can be overcome:

- Miniaturization: Hearing aids are incredibly small, often requiring PCBs with dimensions under 10 mm x 10 mm. This demands high-density interconnect (HDI) designs with trace widths as narrow as 0.075 mm to fit all necessary components.

- Power Constraints: With limited battery capacity (often zinc-air batteries with voltages around 1.4V), PCBs must be designed for ultra-low power consumption. This involves selecting components with quiescent currents in the microampere range.

- Signal Integrity: The audio signals processed by hearing aids must remain clear and free from interference. PCB layouts must minimize crosstalk and electromagnetic interference (EMI), often by using ground planes and maintaining signal trace impedances around 50-75 ohms.

- Durability: Hearing aids are exposed to moisture and earwax, which can damage electronics. Custom PCBs often require conformal coatings or moisture-resistant materials to ensure a lifespan of 3-5 years under daily use.

At ALLPCB, we tackle these challenges by leveraging advanced manufacturing techniques and rigorous testing protocols to deliver high-quality, reliable PCBs for hearing aid applications.

The Future of Custom PCB Design in Personalized Hearing Aids

The field of hearing aid technology is evolving rapidly, and custom PCB design is at the forefront of this transformation. Emerging trends point to even greater personalization and functionality in the years ahead. For instance, the integration of artificial intelligence (AI) into hearing aids could allow devices to learn a user’s listening habits and automatically adjust settings. Custom PCBs will need to support AI processors with clock speeds exceeding 200 MHz while maintaining low power draw.

Additionally, advancements in 3D printing and flexible electronics are paving the way for fully customized hearing aid shells with integrated PCBs. This could reduce production times and costs, making personalized hearing aids more accessible to a wider audience. As these technologies mature, the role of patient-specific PCBs will only grow in importance.

How ALLPCB Supports Custom Hearing Aid PCB Development

At ALLPCB, we are committed to empowering medical device manufacturers with cutting-edge PCB solutions. Our expertise in custom PCB design allows us to create patient-specific PCBs that meet the stringent demands of hearing aid applications. From high-density layouts to flexible designs, we offer a range of services to bring personalized hearing aids to life.

Our process begins with a deep understanding of the client’s requirements, including the patient’s audiogram data and lifestyle needs. We then use advanced design tools to craft PCBs with precise specifications, ensuring optimal performance in sound processing, power management, and durability. With fast prototyping and strict quality control, we help manufacturers iterate quickly and bring their products to market with confidence.

Conclusion: Designing for a Better Hearing Experience

Custom PCB design is revolutionizing the way hearing aids meet individual patient needs. By focusing on patient-specific PCBs and design variations, manufacturers can create personalized hearing aids that deliver superior sound quality, comfort, and functionality. From frequency customization to noise reduction and wireless connectivity, the possibilities are endless when PCBs are tailored to the user.

As technology continues to advance, the role of custom PCB design in hearing aids will only become more critical. At ALLPCB, we’re proud to be part of this journey, providing innovative solutions that help people hear the world around them more clearly. If you’re looking to develop personalized hearing aids with cutting-edge PCB technology, our team is ready to assist in turning your vision into reality.

ALLPCB

ALLPCB