If you're looking to reduce PCB assembly cost for consumer electronics without sacrificing quality, you're in the right place. At ALLPCB, we understand the challenges of balancing affordability with performance in consumer electronics assembly. In this comprehensive guide, we'll explore proven strategies and PCB assembly techniques to help you achieve cost-effective PCB assembly. From design optimization to smart component selection, we'll cover actionable steps to save money and maintain high standards in your projects.

Why Cost-Effective PCB Assembly Matters for Consumer Electronics

Consumer electronics, such as smartphones, wearables, and smart home devices, demand compact, reliable, and affordable printed circuit boards (PCBs). With tight profit margins and high competition in this industry, keeping PCB assembly cost low is crucial. A single misstep in design or production can lead to increased expenses, delayed timelines, or product failures. By focusing on cost-effective PCB assembly, manufacturers can meet market demands while ensuring durability and performance.

In this blog, we'll dive into practical ways to optimize your consumer electronics assembly process. Whether you're a startup or an established company, these strategies will help you save on costs without compromising quality.

Key Factors Influencing PCB Assembly Cost

Before exploring specific PCB assembly techniques, it's important to understand the factors that drive up costs in consumer electronics assembly. By identifying these elements, you can target areas for savings.

- Component Selection: High-cost or hard-to-source components can significantly increase expenses. Choosing widely available, standard parts helps lower costs.

- Board Complexity: Multi-layer boards or intricate designs require more time and resources during manufacturing and assembly.

- Volume of Production: Small batch runs often cost more per unit compared to high-volume production due to setup fees and economies of scale.

- Assembly Method: Manual assembly is more expensive than automated processes, especially for large-scale production.

- Testing and Quality Assurance: Rigorous testing ensures reliability but adds to the overall PCB assembly cost.

With these factors in mind, let’s explore actionable strategies for achieving cost-effective PCB assembly.

Strategies for Cost-Effective PCB Assembly in Consumer Electronics

1. Optimize PCB Design for Manufacturability

Design for Manufacturability (DFM) is a critical step in reducing PCB assembly cost. A well-thought-out design minimizes errors, speeds up production, and lowers expenses. Here are some DFM tips tailored for consumer electronics assembly:

- Simplify Layouts: Reduce the number of layers in your PCB if possible. For instance, a 2-layer board is often sufficient for simpler consumer devices and costs less than a 4-layer or 6-layer board.

- Standardize Component Sizes: Use components with standard footprints (like 0805 or 0603 for resistors and capacitors) to avoid custom fabrication fees.

- Minimize Via Usage: Excessive vias increase drilling costs and manufacturing time. Aim for a via density of less than 100 per square inch for cost efficiency.

- Avoid Tight Tolerances: Unless absolutely necessary, stick to standard tolerances (e.g., ±10% for trace widths) to prevent additional manufacturing steps.

By focusing on DFM, you can streamline the transition from design to production, saving both time and money in PCB assembly techniques.

2. Choose Cost-Efficient Components

Component selection plays a huge role in PCB assembly cost. For consumer electronics assembly, where size and price are often constraints, consider these tips:

- Use Generic Components: Opt for widely available, off-the-shelf components instead of specialized or branded ones. For example, a standard 3.3V regulator can often replace a more expensive, application-specific part.

- Bulk Purchasing: Buy components in larger quantities to benefit from volume discounts. This is especially effective for resistors, capacitors, and LEDs, which are used in high numbers.

- Check Lead Times: Avoid components with long lead times, as delays can increase costs through rushed shipping or production halts.

By carefully selecting components, you can achieve significant savings without affecting the performance of your consumer electronics.

3. Leverage Automated Assembly Processes

Automation is a game-changer for cost-effective PCB assembly. While manual assembly might be suitable for prototypes or very small runs, automated pick-and-place machines and reflow soldering are far more efficient for larger volumes. Here’s why automation works:

- Speed: Automated systems can place thousands of components per hour, compared to manual placement rates of just a few hundred.

- Accuracy: Machines reduce human error, ensuring precise placement and soldering, which minimizes rework costs.

- Scalability: Automation is ideal for scaling up production to meet the high demand for consumer electronics.

Partnering with a manufacturer that uses advanced automation can significantly lower your PCB assembly cost for consumer electronics assembly.

4. Focus on Small Batch Optimization for Prototyping

For startups or companies testing new consumer electronics, small batch runs are common during the prototyping phase. However, small runs often come with higher per-unit costs. To make this stage more cost-effective:

- Consolidate Orders: Combine multiple small projects into a single order to reduce setup fees.

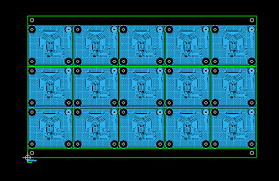

- Use Panelization: Place multiple PCB designs on a single panel to maximize material usage and lower fabrication costs.

- Limit Iterations: Thoroughly test your design in simulation software before ordering physical prototypes to avoid costly redesigns.

These steps ensure that even small-scale PCB assembly techniques remain affordable.

5. Reduce Testing Costs Without Sacrificing Quality

Testing is essential for ensuring the reliability of consumer electronics, but it can add to the overall PCB assembly cost. To keep expenses down:

- Prioritize Key Tests: Focus on critical tests like in-circuit testing (ICT) for high-risk components rather than exhaustive testing for every board.

- Use Automated Testing Equipment: Automated test systems can quickly identify faults, reducing labor costs compared to manual testing.

- Design with Testability in Mind: Include test points in your PCB layout to simplify the testing process and avoid additional setup costs.

Balancing quality and cost in testing ensures your products meet standards while staying within budget.

Advanced PCB Assembly Techniques for Cost Savings

Beyond basic strategies, there are advanced PCB assembly techniques that can further reduce costs for consumer electronics assembly. These methods require a deeper understanding of manufacturing but offer substantial savings.

1. Surface Mount Technology (SMT) Over Through-Hole

Surface Mount Technology (SMT) is widely used in consumer electronics due to its cost efficiency and compatibility with compact designs. Compared to through-hole technology, SMT offers:

- Smaller Components: SMT parts are smaller, allowing for denser PCB layouts ideal for devices like wearables (e.g., components as small as 0201 packages).

- Lower Assembly Costs: SMT components can be placed on both sides of the board, reducing material usage and assembly time.

- Automation-Friendly: SMT is highly compatible with automated assembly lines, further cutting labor costs.

For most consumer electronics, prioritizing SMT over through-hole is a smart way to achieve cost-effective PCB assembly.

2. Minimize Rework with Quality Control

Rework due to assembly errors can skyrocket your PCB assembly cost. Implementing strict quality control measures during production helps avoid this. For example:

- Solder Paste Inspection (SPI): Use SPI to check solder paste application before component placement to prevent soldering defects.

- Automated Optical Inspection (AOI): AOI systems can detect misplaced components or poor solder joints with high accuracy, reducing the need for manual checks.

Investing in quality control upfront saves money by minimizing costly rework later.

3. Collaborate with a Reliable Manufacturing Partner

Partnering with an experienced PCB assembly provider can make a significant difference in achieving cost-effective PCB assembly. A reliable partner offers:

- Volume Discounts: Larger orders often come with reduced per-unit pricing.

- Expert Guidance: Manufacturers can provide DFM feedback to optimize your design for cost savings.

- Streamlined Processes: Established providers have optimized workflows, reducing lead times and costs.

At ALLPCB, we’re committed to helping you navigate the complexities of consumer electronics assembly with tailored solutions that prioritize affordability and quality.

Conclusion: Achieving Cost-Effective PCB Assembly for Consumer Electronics

Reducing PCB assembly cost for consumer electronics doesn’t mean cutting corners on quality. By implementing strategies like design optimization, smart component selection, automation, and advanced PCB assembly techniques, you can achieve cost-effective PCB assembly while meeting the high standards of the industry. Whether you’re producing wearables, smart devices, or other consumer products, these approaches ensure your projects stay within budget and perform reliably.

At ALLPCB, we’re here to support your consumer electronics assembly needs with efficient, affordable solutions. Start optimizing your PCB assembly process today to stay competitive in the fast-paced world of consumer electronics.

ALLPCB

ALLPCB