In PCB design, one important consideration is the variety of hole types used for mounting components, passing signals, or securing the board in an enclosure. One such hole type is the countersink hole, which plays a critical role in enhancing the overall performance and functionality of the PCB.

What is a Countersink Hole?

A Countersink Hole is a hole that has been drilled with a conical shape at the top, designed to allow a countersunk screw or another fastener to sit flush with or below the surface of the PCB. The countersink feature creates a space for the head of a screw to fit into, allowing it to be recessed or sunk below the board's surface. This type of hole is typically used to secure components or for mechanical purposes like attaching the PCB to a chassis.

Countersink or Counterbore?

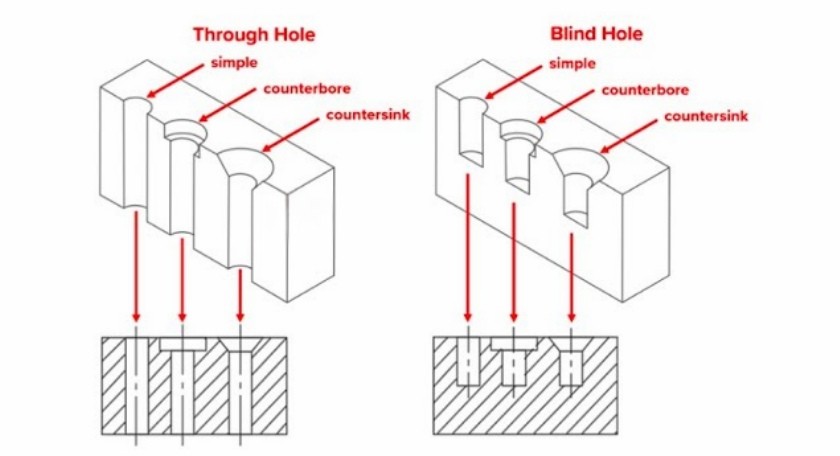

Countersink and Counterbore are both common hole machining methods used to allow screw heads to sit flush with or below the surface of a workpiece. The main difference between them lies in the shape of the hole and their intended purpose.

1. Countersink

-

Shape: A countersink hole has a conical shape at the top, with the diameter gradually widening to form a sloped surface. This sloped surface is designed to accommodate a screw with a conical head.

-

Function: The countersink hole allows the screw head to sit flush with or slightly below the surface of the workpiece. It is commonly used when you need the screw head to be recessed into the surface or to reduce friction.

-

Application: Countersink holes are typically used in thin materials, especially when you need the screw head to be flush with the surface, such as in PCB mounting, woodworking, or metalworking.

2. Counterbore

-

Shape: A counterbore hole has a larger, flat-bottomed portion, where the diameter of the hole increases at the top. It is similar to a cylindrical hole with a larger opening at the top to accommodate the screw head.

-

Function: The counterbore hole is designed to let the screw head sit completely inside the hole, ensuring it is flush with the surface. It is typically used for larger screws or when the screw head needs to be fully recessed.

-

Application: Counterbore holes are commonly used in thicker materials, particularly when you need the screw head to be completely hidden or to ensure the screw is flush with the surface. It is widely used in machining, aerospace, and manufacturing industries.

The Function of Countersink Holes

Countersink holes serve several important functions in PCB design:

-

Improved Mechanical Stability: Countersink holes allow for a flush mount of screws, which secures the PCB firmly into a casing or enclosure without protruding screw heads. This ensures the board stays in place and prevents any movement that might damage components.

-

Aesthetic and Safety Considerations: By allowing screws to sit below the surface, countersink holes reduce the risk of sharp edges or protruding parts that could interfere with other components or wiring. This can also improve the aesthetic quality of the PCB assembly.

-

Ease of Assembly: Countersink holes make assembly and disassembly easier. The smooth, flush fit of screws reduces the risk of damaging delicate parts during assembly or rework.

-

Minimized Stress on the PCB: When properly designed, countersink holes distribute stress from fasteners more evenly, preventing the board from warping or cracking under mechanical loads.

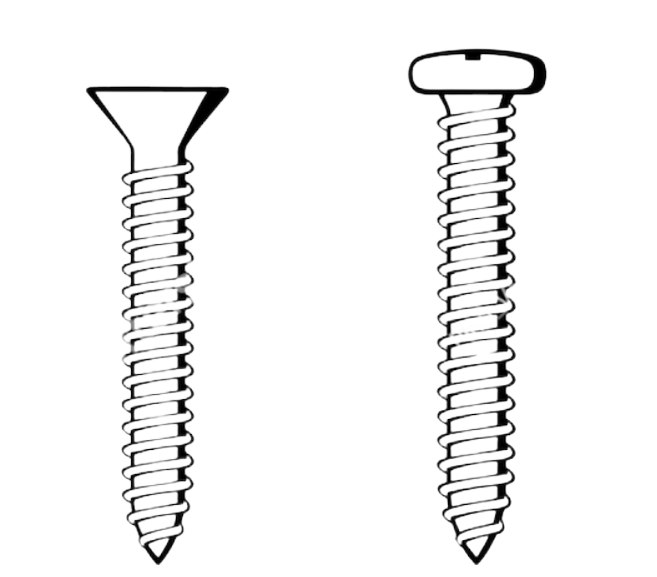

Choose a Suitable Screw

Since there are various types of screws available on the market, you need to have a clear idea before designing which type of screw you prefer for this project. Do you need the screw to be flush with the surface of the board, or should it protrude above the surface? This will determine whether the hole should be designed as a countersink or a counterbore. So at the very beginning of your PCB design, you need to carefully consider this point.

Right: Cap-head screw suitable for counterbore

How to Design Countersink Holes in PCB

Designing countersink holes requires careful attention to several factors to ensure that the holes are both functional and compatible with the assembly process. Below are some key design considerations:

-

Hole Size and Screw Compatibility: The diameter of the countersink hole must match the size of the screw head it is intended to accommodate. For example, if you’re using a #4 screw, the countersink hole should be designed to fit the screw’s diameter, and the angle of the hole should match the screw’s head angle (usually 82° for most screws).

-

Countersink Angle: The angle of the countersink is critical to ensuring that the screw head sits flush with the PCB. The most common angles are 82°, 90°, and 100°, but the correct angle depends on the type of screw and the mechanical requirements. Ensure that the PCB manufacturer can accommodate the selected angle.

-

Hole Depth: The depth of the countersink hole needs to be deep enough to allow the screw head to sit fully inside without damaging the PCB. Ensure that the depth is sufficient for the screw to tighten properly without bottoming out or failing to secure the component.

-

Material Considerations: The PCB material also plays a role in countersink design. For example, fiberglass-based PCBs may require a slightly different countersink design than plastic PCBs due to their different properties. It’s important to work with your PCB manufacturer to understand the best design practices for your specific material.

-

Avoiding PCB Damage: Over-drilling the countersink hole can damage the PCB, especially in areas where trace routing or component placement is critical. Use design tools to check for any potential interference with traces, vias, or components.

-

Placement of Countersink Holes: Ensure that countersink holes are placed in areas that won’t interfere with signal traces, components, or other critical parts of the PCB. Countersink holes are typically placed along the edge of the PCB, but this must be considered carefully in the context of the entire design.

How to Place PCB Order with Countersink Hole at ALLPCB?

-

Choose Countersink Hole/Step Hole in the Advanced Option.

-

Please specifically mention the location of the countersink you designed in the document, and indicate the specific values for D1, D2, Depth, and Angle in the PDF drawing as shown in the image above.

-

Don't forget to specify whether the countersink hole should be drilled from the front or the back of the PCB.

-

If you want to make sure everything is perfect, feel free to contact your sales representative or find us on Livechat.

Feel free to explore our products in more detail:Instant PCB Quote Online, Quick Order - ALLPCB

Special Designs

Just like in PCB design, where drilling holes can be categorized into through holes and blind/buried holes, countersink holes can also be made as through or blind types. What we discussed earlier was the normal through countersink hole, while the blind countersink hole presents a higher manufacturing difficulty. Essentially, it is a type of controlled depth milling groove. The main use of this design is for applications such as attaching a heat sink or securing a component in a specific position.

Conclusion

Countersink holes are an important feature in PCB design, serving both mechanical and aesthetic purposes. They allow screws to sit flush with the board, providing a clean and secure mounting solution. When designing countersink holes, it is essential to consider factors such as screw compatibility, countersink angle, hole depth, and PCB material to ensure functionality and avoid potential issues during manufacturing and assembly. By following these design best practices, you can improve the overall quality and performance of your PCB.

ALLPCB

ALLPCB