7 Steps to Finish Electronic PCB Assembly

Electronic Assembly Definition

After creating the printed circuit boards(To learn printed circuit boards, click here), the next important step is to assemble them efficiently for the completion of the mechanism. Electronic board assembly is the process of mounting various electronic components to a PCB. ALLPCB is a top-speed PCB assembly company in China, that provides high-quality and cheap PCB. Having offered custom electronic circuit board assembly solutions to meet customers’ design specifications, ALLPCB has many years of experience in PCB manufacturing and electronic PCB assembly.

Once electronic components are soldered, the board is called Printed Circuit Board Assembly (PCBA). The traces or conductive pathways engraved in the laminated copper sheets of PCBs are used within a non-conductive substrate in order to form the assembly. When it comes to electronic pcb assembly, SMT is the most frequently used process in the industry.

Since its launch, ALLPCB.com is committed to supplying circuit board manufacturing for the makers, electronic engineers, and all electronic users. We have certified ISO 9001 and work in our PCB and PCB assembly lines. Our diverse domestic and overseas manufacturing capabilities allow us to produce top-quality circuit board assemblies at far lower costs than our competitors.

Where to Find Electronic PCB Assembly Service?

Electronic manufacturers often rely on many different vendors and contractors to secure their materials, sub-assemblies, and other components to deliver their products to customers. ALLPCB is in charge of the entire process from PCB manufacturing to assembly. You don't have to communicate with several different vendors and no worries without order delay. Our clients know they can count on us.

Whatever the challenge is, our team of program managers and engineers work hard to develop solutions from system design to assembly, even when manufacturing includes exception processes or manual steps. The sales team is 24 hours ready to help customers order smoothly. We can also offer obsolescence management services to ensure a stable supply of products for a required period of time.

Turnkey Service of Electronic PCB Assembly

If you need electronic assembly in China, ALLPCB can help. For years we've developed our business to offer customer support and comprehensive service that you need exactly as simply as possible.

From circuit board prototypes all the way up to electronic circuit board assembly, combined with a variety of services, we offer advanced equipment and skilled employees to ensure that quality characterizes every assembly project.

Here’s a quick video to show you all the steps in the ALLPCB factory

An electronic PCB assembly at ALLPCB typically goes through 7 steps:

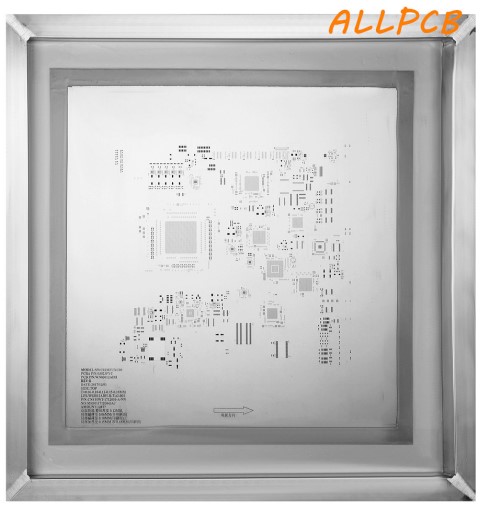

1. Making Stenciling

Making stencils just like silk screen stenciling a t-shirt. You have a mold that you lay over the things you want to apply ink to, which can save much time. In the PCB industry, we use a metal stencil to apply the paste to very specific parts of a PCB.

In ALLPCB, we start with a PCB panel. Panels are a larger board with the design repeated several times over, to make handling easier. We also provide stencils, click here for a quotation. We make these larger panels so that we can stencil multiple boards at the same time. However, you can just make one board at home.

2. Testing Machine

Before starting the assembly process, the first thing for the ALLPCB factory to do is test the machine, which can ensure the production process goes smoothly.

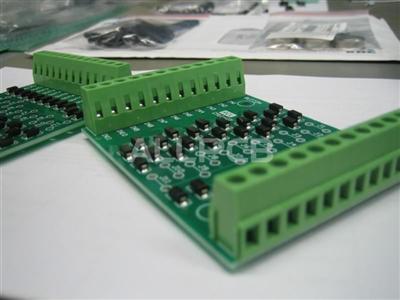

3. Placement

The electronic parts are to be assembled on PCB boards, coming in trays or reels, which are then loaded into the assembly machine. During the loading process, intelligent systems will ensure components are not switched or mis-loaded by accident.

Next, the assembly machine will automatically remove components with a vacuum pipette and places them on the correct position of the board by precisely pre-programmed X-Y coordinates. After the SMT assembly is completed, the boards are removed to the Reflow ovens for soldering, which affixes the components to the board.

4. Reflow

After pick-and-place, the paste must be sent to the reflow process to create a solid solder joint. The boards will be put on a conveyor belt which moves through a large oven, exposing the boards to enough heat to melt the solder. As the board moves through the oven, it encounters different temperature zones, allowing it to warm up and cool down at a controlled rate.

5. Manual Soldering

After reflow, a technician takes the board and manually solders any PTH (plated through-hole) components. In a larger production facility, the soldering of through-hole components may be done using a technique known as wave soldering, where the circuit board is passed over a pan of molten solder in which a pump produces an upwelling of solder that looks like a standing wave.

Because of the high mix of different designs and quantities at ALLPCB, it’s easier to apply as much as possible to SMD (surface mount devices) and hand-solder any PTH components.

6. Inspection and Testing

In order to ensure the quality of all assembled boards, or to catch and correct a mistake, AOI visual inspections are performed in almost all series production processes. Using several cameras, the AOI system automatically checks each board and compares the appearance of each board with the correct, pre-defined reference image.

If there is any deviation, the operator of the machine will be informed of the potential problem, who then will correct the mistake or pull out the board from the machine for further inspection. The AOI visual check ensures consistency and accuracy in the SMT assembly production process.

7. Packaging

The finished PCB board!

ALLPCB uses static-shielding bags to package PCB boards.

What Type of Electronic PCB Assembly?

There are mainly two types of electronic assemblies: through-hole and surface-mount, also called SMT assemblies. For through-hole assembly, leads of the necessary electronic components are inserted directly into through holes on the circuit board. For SMT assembly, components are placed on the outer surface of the printed circuit board.

Through-hole and SMT assembly technology can also be combined into a single circuit board assembly, according to the types of components required. After the components and their leads are placed, the leads are soldered to the board assembly to complete electrical and mechanical connections.

Soldering can be finished by various means. For large quantities, the soldering process may use automatic specialty equipment such as SMT assembly. Smaller quantities or parts that are very small dimensionally may be soldered by hand by skilled technicians. Extremely small assemblies may require the use of tweezers, fine-tip soldering irons, and microscopes.

How Does Electronic PCB Assembly Service Benefit Your Business?

1. Turnkey service

Instead of purchasing components from different vendors, why not consolidate your entire electronic assembly to ALLPCB.com and enjoy the full range of our capabilities and experience? We are confident in our ability to deliver the highest quality electronic assembly for any project.

2. Coherent service

A single electronic manufacturing service will know your build from start to finish. You don’t have to waste time coordinating with different people at different locations.

ALLPCB will assign a dedicated team member who will act as a sort of in-house expert on your entire build. This increases efficiency in the build process because when one person oversees every step, they can address problems before they arise.

3. Save shipping costs

One vendor providing the full turnkey electronic assembly can take advantage of efficiency in moving from one step to another to deliver a better price. As your single-source electronics manufacturer, ALLPCB knows your entire build and can provide packing and shipping solutions that are best for your project.

Packaging is an integral part of the project but is often overlooked or given low priority. Getting the right packaging materials is important for safe delivery.

Quality & Professional Service You Can Trust

Quality is critical in PCB production. Our customers choose ALLPCB.com because we ensure that the best final quality PCB will be shipped. All our manufacturing facilities are ISO 9001 certified. We constantly update and improve the equipment in our facilities to best fit our customers’ PCB orders.

We have 100+ new customers registered with us every day, and many coming to us as referrals from our satisfied customers. Our quality control engineers will routinely perform an inspection of your PCB in the middle of production and before shipment. Besides the visual check, 100% of the boards will also be tested by appropriate testing machines.

Quality is the main factor of word of mouth which helps spread ALLPCB around the world. PCB business is a business that needs heavy involvement of professional engineers, concerning the clarification of technical specifications and fixing of technical problems with our customers.

All your orders will be receiving a free engineering file review service from our trained and professional technicians, before transferring your orders to fabrication sections to minimize errors. Our engineers are also good businessmen who know how to save cost for our customers, and will of course check the quality before shipment and make sure that these shipped PCBs are compliant with your requests.

Suggest Download: