If you're working on a project that requires a single-sided PCB, one of the first decisions you'll need to make is selecting the right substrate material. The substrate forms the foundation of your PCB, impacting its performance, durability, and cost. Common options for single-sided PCB substrate materials include FR4, CEM-1, and phenolic resin-based boards. In this guide, we'll break down the properties of these materials, their applications, and how to choose the best one for your project. Whether you're designing for a simple consumer device or a more demanding application, understanding single-sided PCB material properties will help you make an informed decision.

Let’s dive into the details of single-sided PCB materials like FR4, CEM-1, and phenolic resin, exploring their strengths, weaknesses, and ideal use cases to ensure your project succeeds.

What Are Single-Sided PCBs and Why Do Materials Matter?

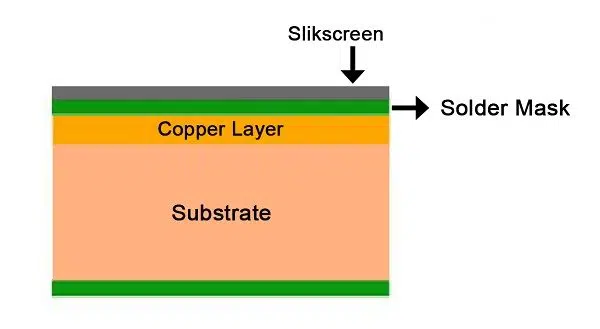

Single-sided PCBs are printed circuit boards with conductive traces on only one side of the substrate. They are widely used in simple electronic devices due to their low cost and ease of manufacturing. Think of basic calculators, LED lighting, or remote controls—these often rely on single-sided PCBs. However, the substrate material you choose directly affects the board’s mechanical strength, thermal resistance, and electrical performance.

Choosing the wrong material can lead to issues like poor heat dissipation, cracking under stress, or unreliable electrical insulation. That’s why understanding single-sided PCB substrate materials is critical. The right material ensures your board performs well under the specific conditions of your project, whether it’s exposed to high temperatures, humidity, or mechanical stress.

Overview of Common Single-Sided PCB Substrate Materials

Let’s explore the most common materials used for single-sided PCBs: FR4, CEM-1, and phenolic resin-based substrates. Each material has unique properties that make it suitable for specific applications.

1. FR4 Single-Sided PCB: The Industry Standard

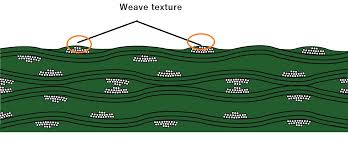

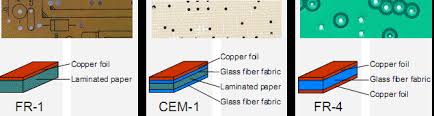

FR4 is the most widely used substrate material for single-sided PCBs. It’s a composite made of woven fiberglass cloth bonded with an epoxy resin. The "FR" stands for "Flame Retardant," meaning it resists catching fire, which is crucial for safety in electronic devices.

Key Properties of FR4 Single-Sided PCB Material:

- Thermal Resistance: FR4 can withstand temperatures up to 130°C without degrading, making it suitable for moderate heat environments.

- Mechanical Strength: With a tensile strength of around 70,000 psi, FR4 is durable and resists cracking or warping.

- Electrical Insulation: It offers excellent dielectric properties with a dielectric constant of about 4.5, ensuring reliable insulation between traces.

- Cost: FR4 is cost-effective for most applications, balancing performance and price.

Applications: FR4 single-sided PCBs are ideal for consumer electronics, automotive systems, and industrial controls where moderate performance and reliability are needed.

Pros: Versatile, widely available, good thermal and mechanical properties.

Cons: Not suitable for high-frequency applications due to signal loss at frequencies above 1 GHz.

2. CEM-1 Single-Sided PCB: A Budget-Friendly Alternative

CEM-1, or Composite Epoxy Material-1, is another popular choice for single-sided PCBs, especially in cost-sensitive projects. It consists of a paper core laminated with epoxy resin and covered with woven glass fabric on the surface.

Key Properties of CEM-1 Single-Sided PCB Material:

- Thermal Resistance: Handles temperatures up to about 110°C, slightly lower than FR4.

- Mechanical Strength: Less robust than FR4, with a tensile strength of around 50,000 psi, making it more prone to damage under stress.

- Electrical Insulation: Dielectric constant of approximately 4.2, providing decent insulation for low to medium voltage applications.

- Cost: Cheaper than FR4, often used in high-volume, low-cost products.

Applications: CEM-1 single-sided PCBs are commonly found in toys, basic household appliances, and other low-power devices where cost is a primary concern.

Pros: Low cost, easy to manufacture, suitable for simple circuits.

Cons: Lower thermal and mechanical performance compared to FR4, not ideal for demanding environments.

3. Phenolic Resin Single-Sided PCB: The Economical Choice

Phenolic resin-based substrates, often referred to as FR-2, are made from paper impregnated with phenolic resin. These are among the most affordable options for single-sided PCBs but come with significant limitations.

Key Properties of Phenolic Resin Single-Sided PCB Material:

- Thermal Resistance: Limited to about 105°C, making it unsuitable for high-heat applications.

- Mechanical Strength: Low tensile strength (around 30,000 psi), prone to cracking or delamination under stress.

- Electrical Insulation: Dielectric constant of around 5.0, adequate for very basic circuits but less reliable under varying conditions.

- Cost: Extremely low, often used in disposable or ultra-low-cost products.

Applications: Phenolic resin single-sided PCBs are used in low-end consumer products like simple calculators, basic toys, or temporary circuits.

Pros: Very cheap, easy to produce in large quantities.

Cons: Poor thermal and mechanical properties, not suitable for complex or long-term use.

Comparing Single-Sided PCB Material Properties

To help you choose the right substrate, let’s compare the single-sided PCB material properties of FR4, CEM-1, and phenolic resin in a clear, side-by-side format.

| Material | Thermal Resistance (°C) | Tensile Strength (psi) | Dielectric Constant | Cost |

|---|---|---|---|---|

| FR4 | 130 | 70,000 | 4.5 | Moderate |

| CEM-1 | 110 | 50,000 | 4.2 | Low |

| Phenolic Resin (FR-2) | 105 | 30,000 | 5.0 | Very Low |

From this table, it’s clear that FR4 offers the best balance of performance and cost for most projects. CEM-1 is a good choice if budget constraints are tight and the application isn’t demanding. Phenolic resin, while the cheapest, should only be considered for the simplest, least critical designs.

How to Choose the Right Substrate for Your Single-Sided PCB Project

Selecting the right single-sided PCB substrate material depends on several factors specific to your project. Here’s a step-by-step guide to help you decide:

Step 1: Assess Environmental Conditions

Consider the operating environment of your PCB. Will it be exposed to high temperatures or humidity? If so, FR4 is likely your best bet due to its superior thermal resistance. For indoor, low-heat applications, CEM-1 or even phenolic resin might suffice.

Step 2: Evaluate Mechanical Stress

If your PCB will face physical stress, such as vibrations or bending, prioritize a material with high tensile strength like FR4. Weaker materials like CEM-1 or phenolic resin may crack or fail under such conditions.

Step 3: Determine Electrical Requirements

For circuits with higher voltage or frequency needs, the dielectric properties of the substrate are crucial. FR4 and CEM-1 provide better insulation than phenolic resin, ensuring signal integrity and safety.

Step 4: Balance Cost and Performance

If your project is for a high-volume, low-cost product, CEM-1 or phenolic resin might be more economical. However, for applications where reliability is key, investing in FR4 will save you from potential failures down the line.

Practical Tips for Working with Single-Sided PCB Materials

Once you’ve chosen your substrate, keep these tips in mind to ensure the best results during design and manufacturing:

- Thickness Matters: Standard thicknesses for single-sided PCBs range from 0.8mm to 1.6mm. Thicker boards (like 1.6mm FR4) offer better durability but may increase costs.

- Copper Weight: The copper layer on single-sided PCBs typically weighs 1 oz/ft2 (35 μm thick). For higher current applications, consider 2 oz/ft2 to handle the load without overheating.

- Soldering Considerations: FR4 and CEM-1 handle soldering temperatures (around 260°C for lead-free solder) well, but phenolic resin may degrade if exposed to prolonged heat.

- Storage Conditions: Store your PCBs in a dry, cool place, as moisture can affect materials like CEM-1 and phenolic resin more than FR4.

Real-World Examples of Single-Sided PCB Material Applications

To illustrate how material choice impacts project outcomes, let’s look at some practical examples:

- LED Lighting Boards: Single-sided FR4 PCBs are often used in LED strips due to their ability to handle moderate heat from the LEDs and provide reliable insulation for low-voltage circuits.

- Children’s Toys: Many battery-operated toys use CEM-1 single-sided PCBs because they’re cheap to produce and the circuits are simple enough not to require high performance.

- Disposable Electronics: Products like one-time-use calculators or greeting cards with sound often use phenolic resin single-sided PCBs to keep costs as low as possible.

Conclusion: Making the Right Choice for Your Single-Sided PCB Project

Choosing the right substrate material for your single-sided PCB is a critical step that affects the performance, cost, and longevity of your project. FR4 single-sided PCBs offer the best balance of thermal resistance, mechanical strength, and electrical insulation for most applications. CEM-1 provides a budget-friendly alternative for simpler designs, while phenolic resin single-sided PCBs are best reserved for ultra-low-cost, non-critical projects.

By understanding single-sided PCB material properties and matching them to your project’s specific needs—such as environmental conditions, mechanical stress, and electrical requirements—you can ensure a successful outcome. Whether you’re designing a robust industrial control board or a basic consumer gadget, the right substrate lays the foundation for reliability and efficiency.

Take the time to evaluate your options and consider factors like operating temperature, durability, and budget. With this guide, you’re well-equipped to make an informed decision on single-sided PCB substrate materials that will support your project from concept to completion.

ALLPCB

ALLPCB