In the rapidly evolving world of healthcare technology, flexible PCBs (Printed Circuit Boards) are playing a transformative role. These innovative components are essential in creating advanced medical devices that are smaller, lighter, and more adaptable to the human body. Whether you're searching for information on flexible PCB for medical devices, medical PCB design, flexible PCB for implantable devices, or flexible PCB for medical sensors, this blog will provide a detailed look at how these technologies are revolutionizing healthcare. At ALLPCB, we are proud to support the medical industry with cutting-edge solutions that drive innovation and improve patient outcomes.

Let’s dive into the world of flexible PCBs and explore their critical applications in advanced healthcare devices, from wearables to implantable systems.

What Are Flexible PCBs and Why Are They Important in Healthcare?

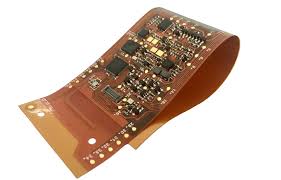

Flexible PCBs are thin, lightweight circuit boards made from flexible materials like polyimide or polyester. Unlike traditional rigid PCBs, they can bend, fold, and conform to various shapes without breaking. This unique property makes them ideal for medical applications where space is limited, and devices need to adapt to the contours of the human body.

In healthcare, the demand for compact, reliable, and biocompatible electronics is growing. Flexible PCBs meet these needs by enabling the design of smaller devices with complex functionalities. Their ability to withstand repeated bending—often up to 100,000 cycles without failure—ensures durability in dynamic environments like wearable health monitors or implantable sensors. This durability is critical when devices must operate continuously inside or on the body without risk of malfunction.

Key Advantages of Flexible PCBs in Medical Devices

Flexible PCBs offer several benefits that make them indispensable in modern medical technology. Here are some of the standout advantages:

- Space Efficiency: Medical devices often need to fit into tight spaces, whether it’s a wearable fitness tracker or an implantable pacemaker. Flexible PCBs can be folded or layered, reducing the overall size of the device by up to 50% compared to rigid alternatives.

- Lightweight Design: With patient comfort in mind, flexible PCBs contribute to lighter devices. For instance, a wearable heart rate monitor using a flexible PCB can weigh as little as 10 grams, making it barely noticeable to the user.

- Durability: These PCBs are designed to endure mechanical stress, such as bending or twisting, which is essential for devices like hearing aids that experience daily movement.

- Biocompatibility: Materials used in flexible PCBs for medical applications are often chosen for their compatibility with the human body, reducing the risk of adverse reactions in implantable devices.

These advantages directly address the challenges faced by engineers working on medical PCB design, ensuring that devices are not only functional but also safe and comfortable for patients.

Applications of Flexible PCBs in Advanced Healthcare Devices

The versatility of flexible PCBs has opened doors to groundbreaking innovations in healthcare. Below, we explore some of the most impactful applications, focusing on areas like wearables, implantables, and sensors.

1. Wearable Medical Devices

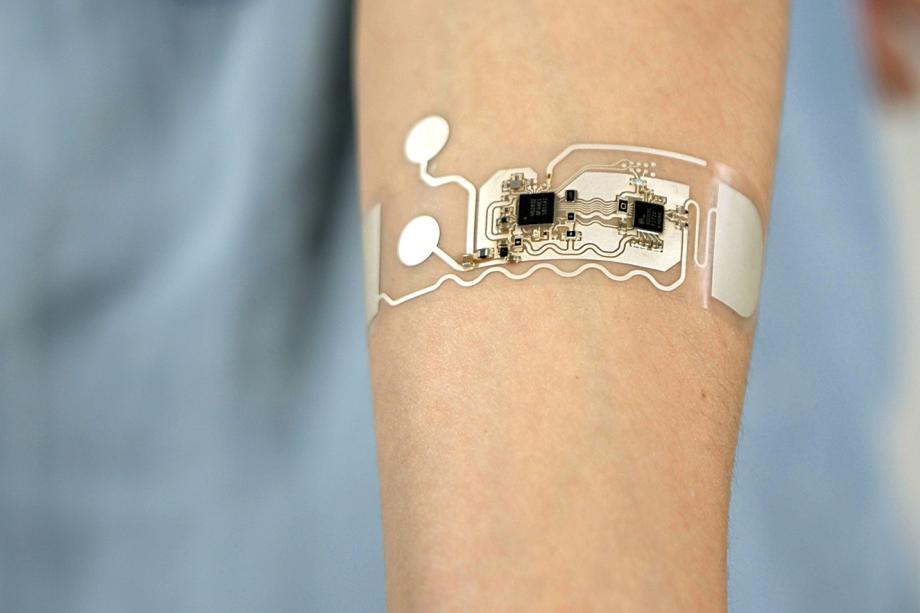

Wearable devices, such as fitness trackers and smart patches, rely heavily on flexible PCBs to monitor vital signs like heart rate, blood oxygen levels, and body temperature. These devices need to conform to the skin for accurate readings and user comfort. A flexible PCB can be integrated into a patch as thin as 0.2 mm, ensuring it adheres seamlessly to the body while maintaining signal integrity for data transmission at speeds up to 1 Mbps.

For example, continuous glucose monitoring systems for diabetic patients use flexible PCBs to create lightweight, skin-friendly devices that provide real-time data to both patients and healthcare providers. The flexibility ensures the device remains in place during daily activities without causing irritation.

2. Implantable Medical Devices

When it comes to flexible PCB for implantable devices, the stakes are even higher. Devices like pacemakers, cochlear implants, and neurostimulators must operate reliably inside the body for years. Flexible PCBs are ideal because they can be shaped to fit within the device’s housing, minimizing space while maintaining low impedance levels—often below 50 ohms—for efficient power delivery.

One remarkable example is in the development of bioresorbable implants. These temporary devices, designed to dissolve naturally after fulfilling their purpose (such as monitoring post-surgical healing), rely on flexible PCBs for their compact design and ability to conform to internal tissues. This reduces the need for additional surgeries to remove the device, improving patient recovery times.

3. Medical Sensors

Flexible PCBs are at the heart of flexible PCB for medical sensors, enabling precise data collection in real-time. Sensors embedded in smart bandages can monitor wound healing by detecting moisture levels or infection markers, transmitting data wirelessly at frequencies around 2.4 GHz. The flexibility of the PCB ensures the bandage molds to the skin without disrupting the healing process.

Additionally, flexible PCBs are used in diagnostic tools like endoscopic cameras. These tiny devices, often less than 5 mm in diameter, navigate through the body to provide high-resolution images. The PCB’s flexibility allows for smooth movement through tight spaces while maintaining signal clarity for video output at resolutions up to 1080p.

Challenges in Medical PCB Design with Flexible Materials

While flexible PCBs offer incredible benefits, designing them for medical applications comes with unique challenges. Engineers must consider several factors to ensure safety and performance:

- Material Selection: The materials must be biocompatible and resistant to bodily fluids. Polyimide, for instance, is often used for its thermal stability (up to 260°C) and chemical resistance.

- Signal Integrity: High-frequency signals in medical sensors can suffer from interference if not properly shielded. Designers often incorporate ground planes to reduce noise, achieving signal-to-noise ratios above 60 dB.

- Regulatory Compliance: Medical devices must meet strict standards, such as ISO 13485 for quality management and IEC 60601 for electrical safety. Flexible PCB designs must account for these requirements from the outset.

- Miniaturization: As devices shrink, maintaining performance becomes harder. For example, a flexible PCB for a microsensor might need to support up to 10 layers in a thickness of just 0.1 mm.

At ALLPCB, we understand these challenges and provide tailored solutions to support engineers in overcoming them, ensuring that every medical PCB design meets the highest standards of quality and reliability.

Future Trends: Flexible PCBs Shaping Healthcare Technology

The future of flexible PCBs in healthcare looks incredibly promising, with several trends emerging that could further transform the industry:

- Integration with AI: Flexible PCBs are being paired with artificial intelligence to create smarter medical devices. For instance, wearable sensors could analyze data locally and predict health issues before they become critical, transmitting alerts at speeds exceeding 5 Mbps.

- Stretchable Electronics: Beyond flexibility, stretchable PCBs are in development, capable of elongating up to 30% without losing functionality. This could lead to even more comfortable wearables and implants.

- Wireless Power: Future implantable devices may use flexible PCBs to support wireless charging, eliminating the need for invasive battery replacements. Current prototypes achieve power transfer efficiencies of over 80% at distances up to 10 cm.

These advancements highlight the growing importance of flexible PCB for medical devices as a cornerstone of healthcare innovation, paving the way for safer, more effective treatments.

How ALLPCB Supports Medical Device Innovation

At ALLPCB, we are committed to empowering the healthcare industry by providing high-quality flexible PCB solutions. Our expertise in manufacturing and design allows us to support complex projects, from prototyping to mass production. We prioritize precision, with tolerances as tight as ±0.05 mm, and offer materials optimized for medical applications, ensuring compliance with industry standards.

Our team works closely with engineers to address the unique needs of flexible PCB for implantable devices and flexible PCB for medical sensors. Whether you’re developing a new wearable or a life-saving implant, we provide the tools and support to bring your vision to life.

Conclusion: The Vital Role of Flexible PCBs in Healthcare

Flexible PCBs are more than just a technological advancement; they are a medical marvel that is reshaping the landscape of healthcare. From enabling compact wearables to powering life-saving implants, their impact is profound and far-reaching. As the demand for smaller, smarter, and more reliable medical devices grows, so too does the importance of innovative solutions like flexible PCB for medical devices.

By addressing the challenges of medical PCB design and pushing the boundaries of what’s possible, flexible PCBs are helping to improve patient outcomes and quality of life. At ALLPCB, we are excited to be part of this journey, supporting the next generation of healthcare technology with our expertise and dedication to excellence.

Whether you’re an engineer designing the next breakthrough device or a healthcare professional seeking cutting-edge tools, understanding the role of flexible PCBs is key to staying ahead in this dynamic field. Let’s continue to innovate and build a healthier future together.

ALLPCB

ALLPCB