In the fast-evolving world of smart parking systems, technology plays a critical role in ensuring efficiency, safety, and user satisfaction. At the heart of these systems lies a key component: High Density Interconnect (HDI) PCBs. These advanced circuit boards, equipped with microvias for PCB integration, are transforming how parking systems operate by boosting performance and reliability. If you're wondering how HDI PCBs can enhance parking solutions, the answer lies in their ability to support compact designs, high-speed data transfer, and long-lasting durability—all essential for modern parking management.

In this blog, we'll dive deep into the role of HDI PCBs in parking systems, exploring their benefits for performance PCBs, PCB speed, and PCB reliability. We'll break down the technology behind these boards, their specific applications, and why they are a game-changer for engineers and system designers in this field.

What Are HDI PCBs and Why Do They Matter?

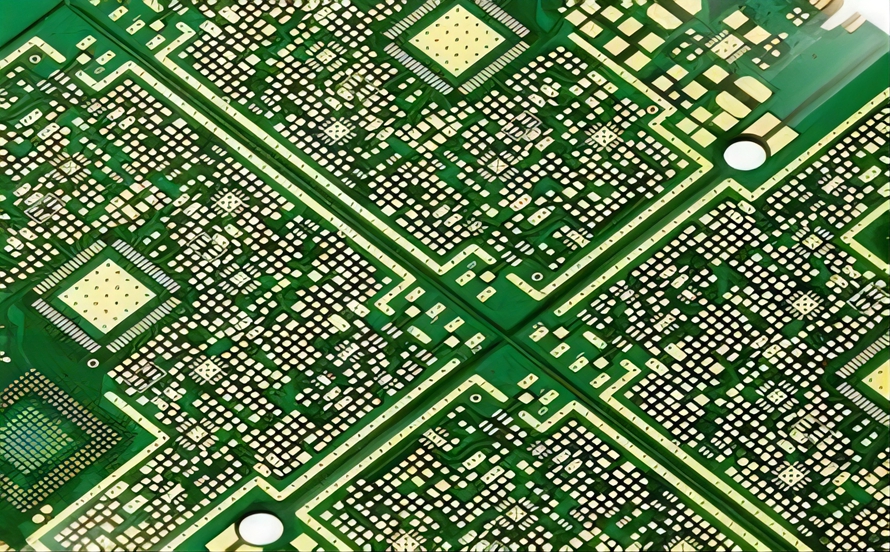

High Density Interconnect (HDI) PCBs are a type of printed circuit board designed to pack more components and connections into a smaller space. Unlike traditional PCBs, HDI boards use microvias—tiny holes drilled with lasers—to create connections between layers. This allows for finer lines, tighter spacing, and a higher wiring density per unit area. The result? A compact, lightweight board that doesn't compromise on functionality.

For parking systems, where space is often limited and reliability is non-negotiable, HDI PCBs offer a perfect solution. These systems rely on sensors, cameras, communication modules, and control units to manage everything from vehicle detection to payment processing. HDI PCBs ensure that all these components work seamlessly together, even in harsh environmental conditions like extreme temperatures or humidity.

The Role of HDI PCBs in Parking Systems

Modern parking systems are more than just barriers and ticket machines. They incorporate advanced technologies like IoT (Internet of Things), AI-driven analytics, and real-time data processing. HDI PCBs are at the core of these innovations, providing the necessary speed and reliability to handle complex tasks. Let's explore how they contribute to parking system performance.

1. Compact Design for Space Efficiency

Parking systems often need to fit into tight spaces, whether it's a control unit in a ticket booth or a sensor embedded in a parking spot. HDI PCBs, with their high component density, allow engineers to design smaller, more efficient devices without sacrificing functionality. For instance, a single HDI board can support multiple sensors and communication chips in a space as small as a few square inches.

2. High-Speed Data Processing with PCB Speed

In smart parking systems, speed is everything. Whether it's processing a license plate image or transmitting payment data to a central server, delays can frustrate users and disrupt operations. HDI PCBs excel in PCB speed due to their shorter signal paths and reduced interference. With microvias enabling precise routing, signal integrity is maintained even at high frequencies, ensuring data transfer rates that can reach up to several gigabits per second in advanced setups.

3. Enhanced PCB Reliability in Harsh Conditions

Parking systems are often exposed to challenging conditions—think rain, snow, or scorching heat in outdoor lots. PCB reliability is critical to prevent failures that could halt operations. HDI PCBs are built with advanced materials and manufacturing techniques, such as sequential lamination, that make them more resistant to thermal stress and mechanical wear. This durability translates to fewer maintenance issues and a longer lifespan for the system.

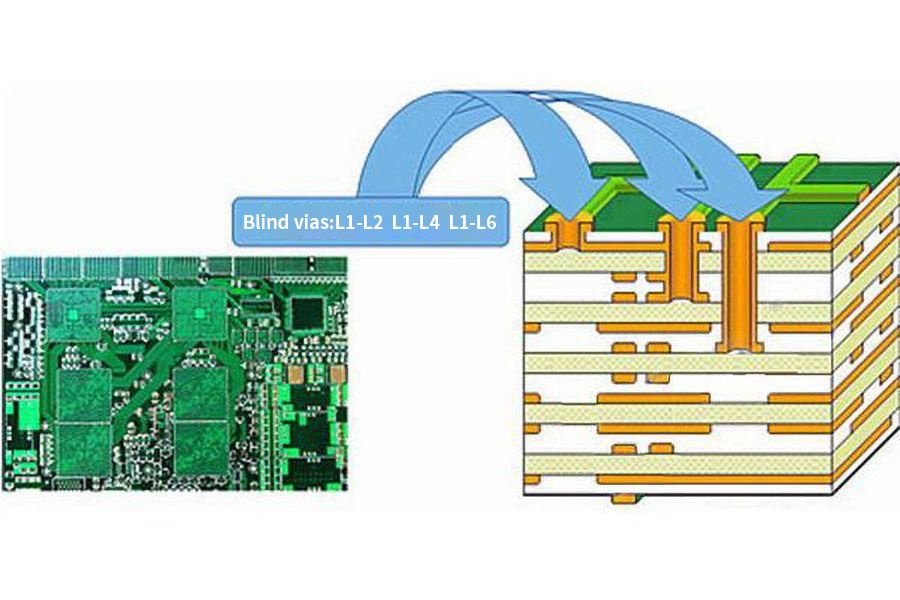

Microvias for PCB: The Secret Behind HDI Success

One of the standout features of HDI PCBs is the use of microvias. These are tiny vias, often less than 0.006 inches in diameter, created using laser drilling technology. Microvias allow for connections between multiple layers of a PCB without taking up much space, enabling the high-density layouts that define HDI boards.

In parking systems, microvias for PCB design play a crucial role in achieving both compactness and performance. For example, a control module managing multiple sensors can use microvias to route signals efficiently between layers, reducing noise and improving response times. Additionally, because microvias are smaller and more precise, they minimize the risk of signal loss, which is vital for maintaining accuracy in data-heavy applications like vehicle detection or occupancy monitoring.

Key Benefits of HDI PCBs for Performance PCBs in Parking Systems

When it comes to performance PCBs, HDI technology offers several advantages that directly impact the efficiency and user experience of parking systems. Here are some of the most significant benefits:

- Improved Signal Integrity: With shorter trace lengths and reduced crosstalk, HDI PCBs ensure cleaner signals, which is essential for high-speed data applications in parking systems.

- Reduced Power Consumption: The compact design and efficient routing lower power loss, making systems more energy-efficient—a key factor for sustainable parking solutions.

- Higher Component Density: More components in a smaller area mean that parking devices can offer advanced features like real-time analytics without increasing in size.

- Better Thermal Management: HDI PCBs often incorporate advanced materials that dissipate heat more effectively, preventing overheating in enclosed or outdoor setups.

Real-World Applications of HDI PCBs in Parking Systems

To understand the true impact of HDI PCBs, let's look at some specific applications within parking systems where their performance and reliability shine.

1. Vehicle Detection and License Plate Recognition

Smart parking systems often use cameras and sensors for vehicle detection and license plate recognition. These components generate large amounts of data that need to be processed quickly and accurately. HDI PCBs, with their high-speed capabilities, ensure that data from multiple cameras is transmitted to the processing unit without delays, enabling real-time monitoring and access control.

2. Payment and Ticketing Systems

From contactless payments to mobile app integrations, payment systems in parking lots require secure and fast data processing. HDI PCBs support the integration of multiple communication protocols (like NFC or Bluetooth) on a single board, ensuring smooth transactions even during peak usage times.

3. IoT Integration for Smart Parking

IoT-enabled parking systems connect sensors, displays, and central servers to provide real-time updates on parking availability. HDI PCBs are ideal for these setups because they can handle the complex wiring and high data rates needed for seamless connectivity. For instance, a single HDI board can manage data from dozens of sensors spread across a parking lot, transmitting it to a cloud server with minimal latency.

Challenges in Implementing HDI PCBs and How to Overcome Them

While HDI PCBs offer incredible benefits, they come with certain challenges that engineers must address during design and manufacturing. Understanding these hurdles can help in creating more robust parking systems.

1. Complex Manufacturing Process

HDI PCBs require advanced techniques like laser drilling for microvias and sequential lamination for multilayer designs. This complexity can increase production time and cost. To mitigate this, partnering with experienced PCB manufacturers who specialize in HDI technology ensures high-quality boards without unnecessary delays.

2. Design Constraints

Designing for HDI requires precision, as even small errors in trace spacing or via placement can lead to signal issues. Using advanced design software and following best practices for HDI layouts can help engineers avoid common pitfalls and achieve optimal performance.

3. Testing for Reliability

Given the critical role of PCB reliability in parking systems, thorough testing is essential. Engineers should conduct environmental stress tests (e.g., thermal cycling from -40°C to 85°C) and signal integrity tests to ensure the board can withstand real-world conditions without failure.

Why Choose HDI PCBs for Your Parking System Projects?

For engineers and system designers working on parking solutions, HDI PCBs are a strategic choice. They provide the perfect balance of performance, reliability, and compactness needed to meet the demands of modern parking management. Whether you're developing a small sensor module or a comprehensive IoT-based parking network, these boards deliver the speed and durability to keep operations running smoothly.

Moreover, as parking systems continue to evolve with technologies like AI and 5G connectivity, the need for high-performance PCBs will only grow. Investing in HDI technology now positions your projects for future scalability and innovation.

Conclusion: Powering the Future of Parking with HDI PCBs

High Density Interconnect PCBs are revolutionizing parking systems by elevating both performance and reliability. From enabling high-speed data processing to ensuring durability in tough conditions, these boards are the backbone of smart parking solutions. With features like microvias for PCB integration, HDI technology allows engineers to create compact, efficient, and powerful systems that enhance user experiences and streamline operations.

As the demand for smarter, more connected parking solutions grows, HDI PCBs will continue to play a pivotal role. By leveraging their capabilities, you can build systems that not only meet current needs but also adapt to future advancements. For anyone in the field of parking system design, understanding and utilizing HDI technology is the key to staying ahead in this dynamic industry.

ALLPCB

ALLPCB