In the fast-evolving world of gaming, staying ahead means designing with the future in mind. If you're an engineer or designer working on gaming console projects, you're likely searching for insights into future trends in gaming console PCB technology, advanced PCB technology for gaming, and innovation in PCB design for gaming. This blog post dives deep into the latest advancements and market trends shaping next-generation gaming console PCB designs, helping you create cutting-edge, future-proof solutions.

From high-speed signal integrity to compact, power-efficient layouts, we'll explore how PCB market trends in gaming are driving innovation. Whether you're optimizing for performance or scalability, this guide offers actionable insights to elevate your designs. Let's unpack the technologies and trends that will define the gaming industry in the years ahead.

The Importance of Future-Proofing Gaming Console PCB Designs

Gaming consoles are at the heart of a multi-billion-dollar industry, with market projections estimating growth to USD 61.2 billion by 2033, according to recent industry reports. As gamers demand faster load times, hyper-realistic graphics, and seamless multiplayer experiences, the pressure is on designers to deliver PCBs that can handle these requirements. Future-proofing your PCB design ensures that your console can adapt to emerging technologies, extend product lifespan, and remain competitive in a crowded market.

But what does future-proofing mean for PCB technology in gaming? It involves anticipating trends like higher processing speeds, increased thermal management needs, and integration of advanced features such as AI and cloud streaming. By understanding and applying the latest innovations, you can design PCBs that not only meet current standards but also accommodate upgrades and new functionalities down the line.

Key Trends Shaping Future Gaming Console PCB Technology

Let’s break down the most significant trends influencing next-generation gaming console PCB designs. These advancements are driven by the need for speed, efficiency, and adaptability in an industry that’s constantly pushing boundaries.

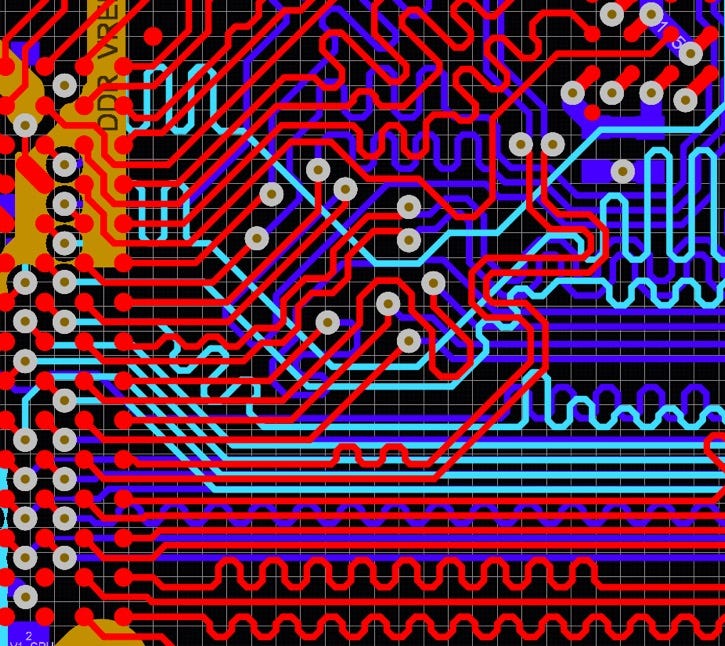

1. High-Speed Signal Integrity for Ultra-Fast Performance

As gaming consoles evolve into their ninth generation and beyond, they require PCBs capable of supporting data transfer rates exceeding 10 Gbps for features like 8K resolution and real-time ray tracing. High-speed signal integrity is critical to prevent data loss or interference, especially with the integration of technologies like DDR5 memory and PCIe 5.0 interfaces. Designers are now focusing on minimizing signal crosstalk by optimizing trace layouts and using materials with low dielectric constants, often below 3.5 at 1 GHz, to ensure clean signal transmission.

Additionally, differential pair routing and controlled impedance—typically maintained at 50 ohms for single-ended signals and 100 ohms for differential pairs—are becoming standard practices. These techniques reduce electromagnetic interference (EMI) and ensure that high-frequency signals remain stable even under heavy processing loads.

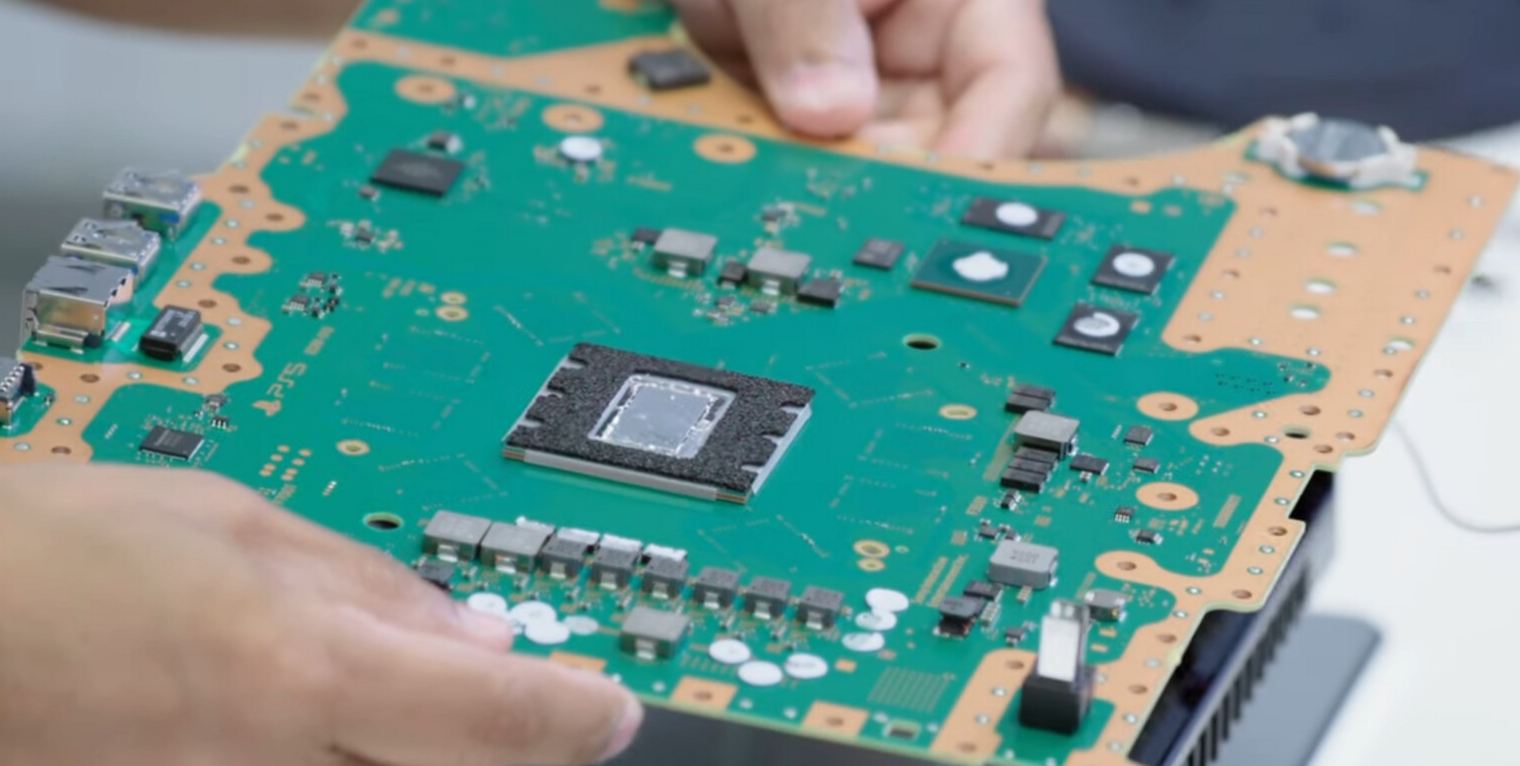

2. Miniaturization and High-Density Interconnect (HDI) Technology

With gamers expecting sleeker, more portable consoles, the push for miniaturization has led to widespread adoption of High-Density Interconnect (HDI) technology in PCB design. HDI allows for more components to be packed into smaller spaces by using microvias and finer trace widths, often as small as 3 mils (0.003 inches). This is essential for fitting powerful GPUs, CPUs, and storage solutions into compact console designs without sacrificing performance.

HDI also supports multi-layer boards—sometimes up to 12 layers or more in advanced gaming consoles—enabling complex routing while maintaining a small footprint. This trend is particularly important as advanced PCB technology for gaming moves toward integrating more functionalities, such as wireless connectivity and advanced cooling systems, directly onto the board.

3. Advanced Thermal Management Solutions

Gaming consoles generate significant heat due to high-performance processors and graphics units running at clock speeds above 3 GHz. Poor thermal management can lead to throttling, reduced lifespan, or even system failure. To address this, PCB designers are incorporating advanced thermal vias and heat dissipation materials, such as copper coin technology, which can improve heat transfer by up to 30% compared to traditional methods.

Moreover, the use of thermally conductive substrates with coefficients as high as 1.5 W/mK helps dissipate heat more effectively. Some designs even integrate embedded heat pipes or vapor chambers directly into the PCB stack-up, ensuring that critical components stay within safe operating temperatures, typically below 85°C, even during extended gaming sessions.

4. Integration of AI and IoT Capabilities

The future trends in gaming console PCB are heavily influenced by the integration of artificial intelligence (AI) and Internet of Things (IoT) features. AI-driven non-player characters (NPCs) and adaptive gameplay require dedicated neural processing units (NPUs) on the PCB, while IoT enables seamless cloud streaming and remote updates. These additions demand more complex circuitry and power management systems to support always-on connectivity and real-time data processing.

For instance, power delivery networks (PDNs) must now handle fluctuating loads with voltage tolerances as tight as ±5% to prevent glitches during AI computations. Designers are also incorporating secure communication protocols directly into the PCB layout to protect against cyber threats, a growing concern as consoles become more connected.

5. Sustainable and Eco-Friendly Materials

As environmental regulations tighten and consumer awareness grows, the gaming industry is shifting toward sustainable PCB manufacturing. Halogen-free laminates and lead-free soldering materials are becoming standard to reduce environmental impact. Some manufacturers are even exploring bio-based resins for PCB substrates, which can cut carbon footprints by up to 20% compared to traditional epoxy materials.

This trend aligns with broader PCB market trends in gaming, where companies are balancing performance with eco-conscious design. Using recyclable materials and optimizing board layouts to minimize waste during production are practical steps designers can take to contribute to sustainability goals.

Innovations Driving Next-Generation Gaming Console PCB Designs

Beyond trends, specific innovations are transforming how PCBs are designed and manufactured for gaming consoles. These breakthroughs in innovation in PCB design for gaming are paving the way for more powerful, efficient, and adaptable systems.

1. 3D-Stacked PCB Architectures

Traditional flat PCB designs are giving way to 3D-stacked architectures, where multiple layers or even separate boards are vertically integrated using through-silicon vias (TSVs). This approach reduces signal latency by shortening interconnect lengths—sometimes by as much as 50%—and allows for greater component density. For gaming consoles, 3D stacking is ideal for combining high-performance CPUs and GPUs with memory modules in a single compact package.

This innovation also improves power efficiency, as shorter traces reduce resistance and parasitic capacitance, leading to energy savings of up to 15% in some designs. As consoles aim for lower power consumption without compromising performance, 3D stacking is a game-changer.

2. Flexible and Rigid-Flex PCBs for Unique Form Factors

The demand for innovative console designs, such as handheld or modular systems, has spurred the use of flexible and rigid-flex PCBs. These boards can bend or fold to fit unconventional shapes, making them perfect for portable gaming devices. Rigid-flex designs also enhance reliability by reducing the number of connectors and solder joints, which are common failure points under mechanical stress.

For example, a rigid-flex PCB might combine a rigid section for mounting heavy components like processors with flexible sections for connecting to displays or controllers. This adaptability is key for designers looking to push the boundaries of form factor while maintaining durability.

3. Embedded Components for Streamlined Designs

Embedding passive components like resistors and capacitors directly into the PCB substrate is an emerging technique that saves space and improves performance. By reducing the need for surface-mounted components, embedded designs can cut board size by up to 25% and enhance signal integrity by minimizing parasitic effects.

In gaming consoles, where every millimeter of space counts, this innovation allows for cleaner layouts and better thermal distribution. It also supports the trend toward modular designs, where specific functions can be upgraded without redesigning the entire board.

How to Implement These Trends and Innovations in Your Designs

Understanding future trends in gaming console PCB and innovations is only the first step. Here are practical ways to apply these insights to your projects and ensure your designs are ready for tomorrow’s challenges.

Start with Material Selection: Choose high-frequency laminates with low loss tangents (below 0.005 at 10 GHz) for high-speed applications. For thermal management, prioritize substrates with high thermal conductivity and consider integrating copper inlays for heat dissipation.

Optimize Layouts for Performance: Use simulation tools to model signal integrity and thermal behavior before fabrication. Focus on controlled impedance routing and place decoupling capacitors close to power pins to stabilize voltage, ideally within 0.1 inches of the target component.

Plan for Scalability: Design with modularity in mind, using standardized connectors and interfaces to allow for future upgrades. Allocate extra space or layers in your PCB stack-up for potential additions like AI chips or enhanced wireless modules.

Stay Updated on Industry Standards: Follow advancements in manufacturing processes and materials by engaging with industry forums and resources. Keeping abreast of PCB market trends in gaming ensures you’re not left behind as new technologies emerge.

Challenges in Adopting Advanced PCB Technology for Gaming

While the benefits of advanced PCB technology for gaming are clear, there are hurdles to overcome. Cost is a major concern, as cutting-edge materials and manufacturing techniques like HDI or 3D stacking can increase production expenses by 20-30%. Balancing performance with affordability is crucial, especially for mass-market consoles.

Another challenge is the complexity of design and testing. High-speed and high-density layouts require sophisticated software and expertise to avoid issues like signal crosstalk or thermal hotspots. Investing in training and tools can help mitigate these risks and ensure reliable outcomes.

Conclusion: Building for the Future of Gaming

The gaming industry is on a trajectory of rapid growth and innovation, and PCB technology is at the core of this transformation. By embracing future trends in gaming console PCB design, such as high-speed signal integrity, HDI technology, and sustainable materials, you can create designs that stand the test of time. Innovations like 3D stacking and embedded components further enhance your ability to deliver compact, powerful, and efficient solutions for next-generation gaming console PCB projects.

As you move forward, remember that future-proofing isn’t just about adopting the latest tech—it’s about anticipating needs and building flexibility into your designs. With the right approach, you can stay ahead of PCB market trends in gaming and contribute to the next wave of gaming excellence. Let’s design for the future, one board at a time.

ALLPCB

ALLPCB