If you're looking to prototype heavy copper PCBs, you're likely seeking a reliable way to handle high-current applications with durability and efficiency. Heavy copper PCBs are essential for industries like automotive, power electronics, and industrial equipment, where standard copper layers just won't cut it. In this guide, we'll walk you through the essentials of creating a heavy copper PCB prototype, including quick turn options, small quantity production, and a breakdown of heavy copper PCB prototype cost. Whether you're an engineer or a designer, this quick start guide will help you navigate the process with ease.

At ALLPCB, we understand the unique challenges of prototyping heavy copper PCBs. This blog dives deep into the process, offering practical tips, best practices, and insights to ensure your project succeeds. Let's get started with everything you need to know about heavy copper PCB quick turn, small quantity runs, and cost optimization.

What Are Heavy Copper PCBs and Why Use Them?

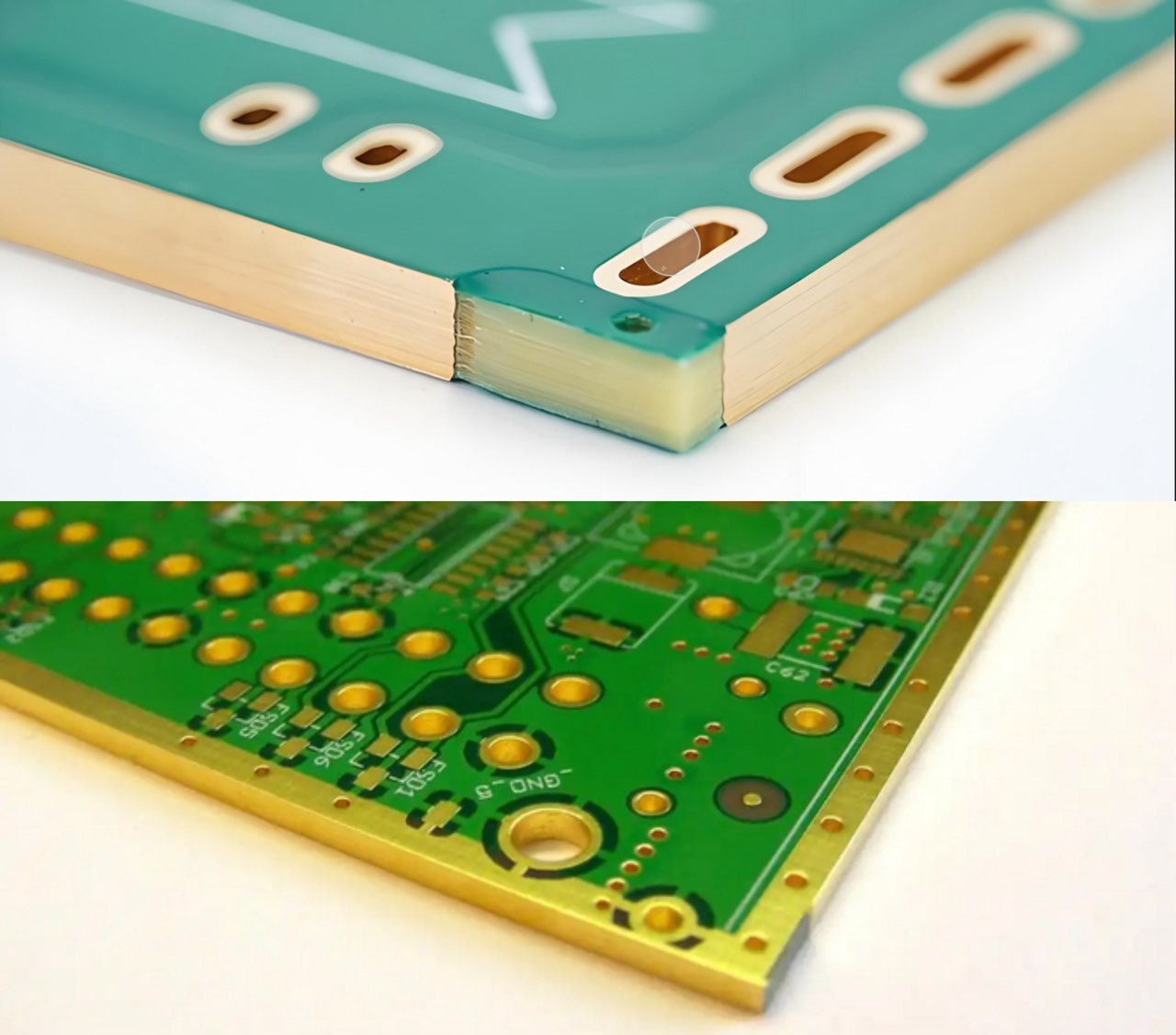

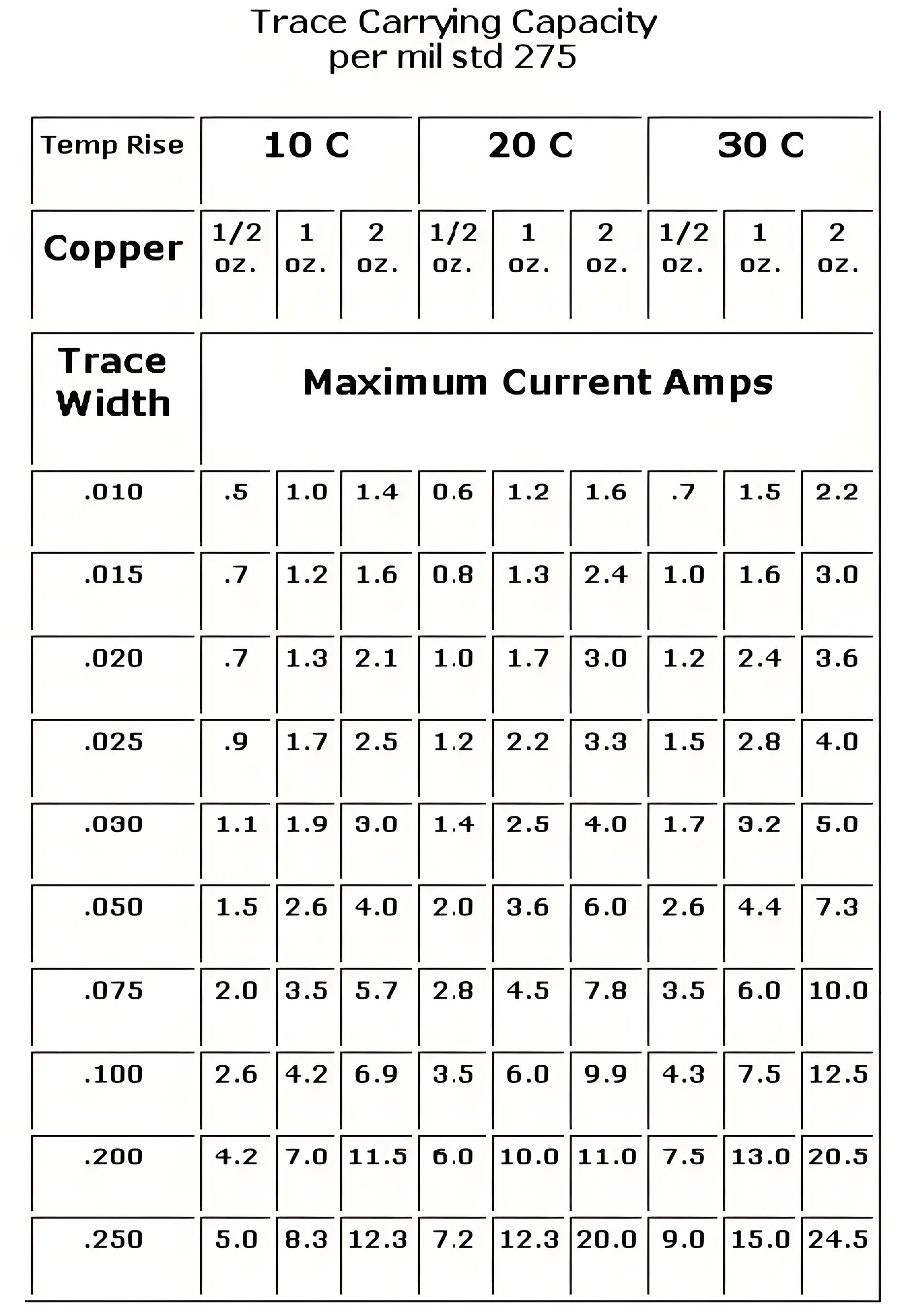

Heavy copper PCBs are printed circuit boards with copper layers thicker than standard PCBs. Typically, heavy copper refers to copper thickness of 3 oz/ft2 or more, compared to the 1 oz/ft2 or 2 oz/ft2 found in regular boards. This increased thickness allows the board to handle higher currents, improve thermal management, and enhance mechanical strength.

These boards are ideal for applications where high power and heat dissipation are critical. For example, in power supply units, the copper thickness can support currents exceeding 10 amps without overheating. In automotive systems, heavy copper ensures reliability under harsh conditions. If your project involves high-power electronics, a heavy copper PCB prototype is often the best choice to test your design before full-scale production.

Benefits of Heavy Copper PCB Prototypes

Prototyping with heavy copper PCBs offers several advantages, especially for engineers working on high-performance designs:

- Higher Current Capacity: With copper thickness ranging from 3 oz to 20 oz per square foot, these boards can carry significant current without risk of failure.

- Better Heat Dissipation: Thicker copper layers act as heat sinks, reducing the risk of overheating in power-intensive applications.

- Durability: The added copper provides mechanical strength, making the board more resistant to thermal stress and vibration.

- Design Flexibility: Heavy copper allows for unique layouts, such as combining heavy and standard copper in a single board for cost efficiency.

For small quantity runs or quick turn projects, prototyping with heavy copper ensures you can test these benefits in real-world conditions before committing to large-scale manufacturing.

Steps to Prototype a Heavy Copper PCB

Creating a heavy copper PCB prototype involves several key steps. Following a structured process ensures your design meets performance goals while staying within budget and timeline constraints. Here's a step-by-step guide to get you started:

1. Define Your Design Requirements

Start by outlining the specific needs of your project. Consider the following:

- Current and Voltage Needs: Determine the maximum current your board will handle. For instance, a 5 oz copper layer can support currents up to 20 amps in many designs.

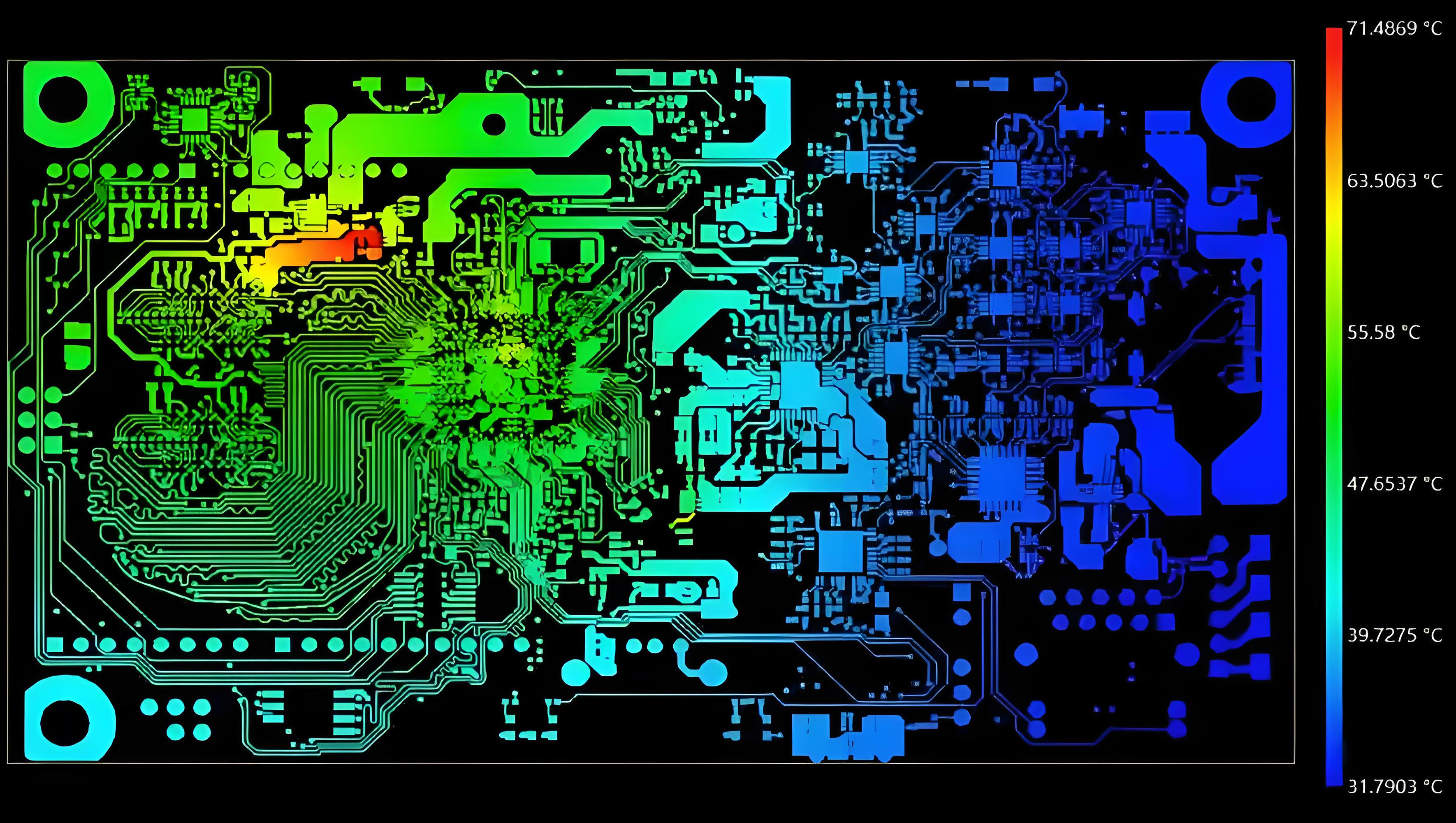

- Thermal Management: Identify areas where heat dissipation is critical to prevent component failure.

- Board Dimensions: Ensure your layout accommodates thicker copper without compromising space for other components.

Clearly defining these parameters helps avoid costly revisions during prototyping.

2. Choose the Right Copper Thickness

Copper thickness is a critical factor in heavy copper PCB design. Common thicknesses range from 3 oz to 10 oz per square foot, though some applications may require up to 20 oz. Thicker copper increases current capacity but also raises manufacturing complexity and cost. For a prototype, start with a moderate thickness, such as 4 oz, to balance performance and affordability.

3. Design Your PCB Layout

Use PCB design software to create your layout, ensuring that traces and pads are wide enough to handle high currents. Pay attention to spacing rules, as thicker copper often requires larger gaps to prevent short circuits. Additionally, consider thermal vias to improve heat dissipation in critical areas.

Keep in mind that heavy copper affects impedance. For high-frequency signals, you may need to adjust trace widths to maintain signal integrity. For example, a 50-ohm impedance line on a 4 oz copper layer may require a trace width of 0.015 inches, depending on the dielectric material.

4. Select Materials and Stack-Up

Heavy copper PCBs often require specialized materials to handle thermal and mechanical stress. FR-4 is a common choice for prototypes due to its cost-effectiveness, but for high-power applications, consider high-Tg materials or metal-core substrates for better heat management.

Your stack-up design should also account for the copper thickness. A typical 4-layer heavy copper PCB might have 4 oz copper on outer layers and 2 oz on inner layers to balance cost and performance.

5. Partner with a Reliable Manufacturer for Quick Turn

For heavy copper PCB quick turn projects, work with a manufacturer that specializes in rapid prototyping. Look for services that offer turnaround times of 24 to 72 hours for small quantity orders. At ALLPCB, we prioritize speed without sacrificing quality, ensuring your heavy copper PCB prototype is ready when you need it.

6. Test and Validate Your Prototype

Once you receive your prototype, conduct thorough testing to verify performance. Measure current capacity, check for thermal hotspots using infrared cameras, and ensure signal integrity with oscilloscopes if your design includes high-speed signals. Testing at this stage helps identify issues before moving to production.

Heavy Copper PCB Quick Turn: Tips for Speed

When time is critical, a heavy copper PCB quick turn service can save your project. Here are some tips to ensure fast delivery without compromising quality:

- Simplify Your Design: Avoid overly complex layouts that require additional manufacturing steps. Stick to standard shapes and minimize custom features for prototypes.

- Provide Clear Documentation: Submit detailed Gerber files, BOM (Bill of Materials), and assembly drawings to avoid delays caused by clarifications.

- Communicate Deadlines: Inform your manufacturer of your timeline upfront. Many offer expedited services for urgent projects.

- Opt for Local or Fast Shipping: Choosing a manufacturer with nearby facilities or priority shipping options can shave days off delivery time.

At ALLPCB, we streamline the process for quick turn heavy copper PCB prototypes, often delivering within a few days for urgent needs.

Heavy Copper PCB Small Quantity: Balancing Quality and Cost

For small quantity runs, such as 5 to 50 units, heavy copper PCB prototyping can be challenging due to setup costs. However, with the right approach, you can keep expenses manageable:

- Batch Orders: Even for small quantities, batching your order with standard panel sizes reduces waste and lowers per-unit cost.

- Optimize Copper Usage: Use heavy copper only where necessary, combining it with standard copper in less critical areas.

- Minimize Layer Count: Reducing the number of layers (e.g., from 6 to 4) can significantly cut costs without affecting performance in many designs.

Small quantity heavy copper PCB orders are ideal for initial testing or pilot projects, and focusing on efficiency ensures you get the most value from each unit.

Heavy Copper PCB Prototype Cost: What to Expect

Understanding heavy copper PCB prototype cost is crucial for budgeting. Costs vary based on several factors:

- Copper Thickness: Thicker copper (e.g., 6 oz vs. 3 oz) increases material and processing costs. A 4 oz prototype might cost 20-30% more than a standard 1 oz board.

- Board Size and Layers: Larger boards or those with more layers require more materials and labor, driving up the price.

- Turnaround Time: Quick turn services often come with a premium, sometimes adding 50% or more to the base cost for 24-hour delivery.

- Quantity: Small quantity orders have higher per-unit costs due to fixed setup fees. For example, producing 10 units might cost $15 per board, while 100 units could drop to $8 per board.

On average, a heavy copper PCB prototype for a small 2-layer board with 4 oz copper might range from $50 to $150 for a batch of 5 units, depending on specifications and turnaround time. For precise pricing, request a quote tailored to your design needs. At ALLPCB, we strive to offer competitive pricing while maintaining high-quality standards.

Common Challenges in Heavy Copper PCB Prototyping

While heavy copper PCBs offer many benefits, prototyping them comes with unique challenges. Being aware of these can help you avoid pitfalls:

- Manufacturing Limitations: Not all facilities can handle copper thicknesses above 6 oz. Ensure your manufacturer has the right equipment.

- Etching Issues: Thicker copper requires longer etching times, which can lead to undercutting or uneven traces if not done properly.

- Thermal Expansion: Heavy copper can cause stress on the board during soldering due to different expansion rates compared to the substrate.

Work closely with your manufacturer to address these issues during the design and production phases. Clear communication and thorough design reviews can prevent most problems.

Best Practices for Successful Heavy Copper PCB Prototyping

To ensure your heavy copper PCB prototype meets expectations, follow these best practices:

- Start with Simulations: Use thermal and electrical simulation tools to predict performance before manufacturing. This can save time and reduce costly revisions.

- Focus on DFM (Design for Manufacturability): Design with manufacturing constraints in mind, such as minimum trace widths and spacing for heavy copper.

- Request Feedback: Share your design files with your manufacturer early to get input on potential issues or optimizations.

- Iterate Based on Testing: Use prototype testing results to refine your design, ensuring the final product is reliable and efficient.

Why Choose ALLPCB for Heavy Copper PCB Prototyping?

At ALLPCB, we specialize in delivering high-quality heavy copper PCB prototypes tailored to your needs. Whether you require quick turn services, small quantity runs, or cost-effective solutions, our team is equipped to handle projects of any complexity. With advanced manufacturing capabilities and a commitment to customer satisfaction, we ensure your heavy copper PCB prototype is delivered on time and meets the highest standards.

Our streamlined process minimizes delays, and our transparent pricing helps you manage heavy copper PCB prototype cost effectively. From design support to final delivery, we're here to make your prototyping journey smooth and successful.

Conclusion

Prototyping heavy copper PCBs doesn't have to be complicated. By understanding the basics of heavy copper design, following a structured prototyping process, and partnering with a trusted manufacturer like ALLPCB, you can bring your high-power projects to life with confidence. Whether you're focused on heavy copper PCB quick turn, small quantity production, or managing heavy copper PCB prototype cost, this guide provides the foundation you need to succeed.

Take the first step today by defining your project requirements and reaching out for a customized solution. With the right approach, your heavy copper PCB prototype will pave the way for reliable, high-performance electronics in no time.

ALLPCB

ALLPCB