If you're looking to create custom PCBs for wearable projects, online PCB fabrication services offer a fast, affordable, and reliable solution. Whether you're a hobbyist designing a fitness tracker or a professional prototyping a smartwatch, ordering PCBs online simplifies the process. In this guide, we'll walk you through the steps to design and order custom PCBs for wearables, explore cost-effective prototyping options, and share tips on using PCB design software for hobbyists. You'll also find PCB layout tutorials to help you get started.

At ALLPCB, we specialize in providing seamless online services for PCB manufacturing and assembly, ensuring your wearable projects come to life with precision and efficiency. Let's dive into the details of creating custom PCBs tailored for compact, lightweight, and power-efficient wearable devices.

Why Custom PCBs Are Essential for Wearable Projects

Wearable technology, like smartwatches, fitness bands, and medical monitoring devices, demands highly specialized printed circuit boards (PCBs). These devices need to be small, lightweight, and energy-efficient while maintaining functionality. Custom PCBs allow you to design boards that fit the exact shape and size of your wearable, optimize power consumption, and integrate specific components like sensors or Bluetooth modules.

Using online PCB fabrication services makes this process accessible to everyone. You can upload your design files, choose materials, and have prototypes delivered to your door in days. This eliminates the need for expensive in-house equipment or complex manufacturing setups, saving both time and money.

Step 1: Designing Your PCB for Wearable Projects

The first step in creating a custom PCB for a wearable project is designing the board. Since wearables are small, the design must prioritize space efficiency and low power usage. Here’s how to get started with PCB design software for hobbyists.

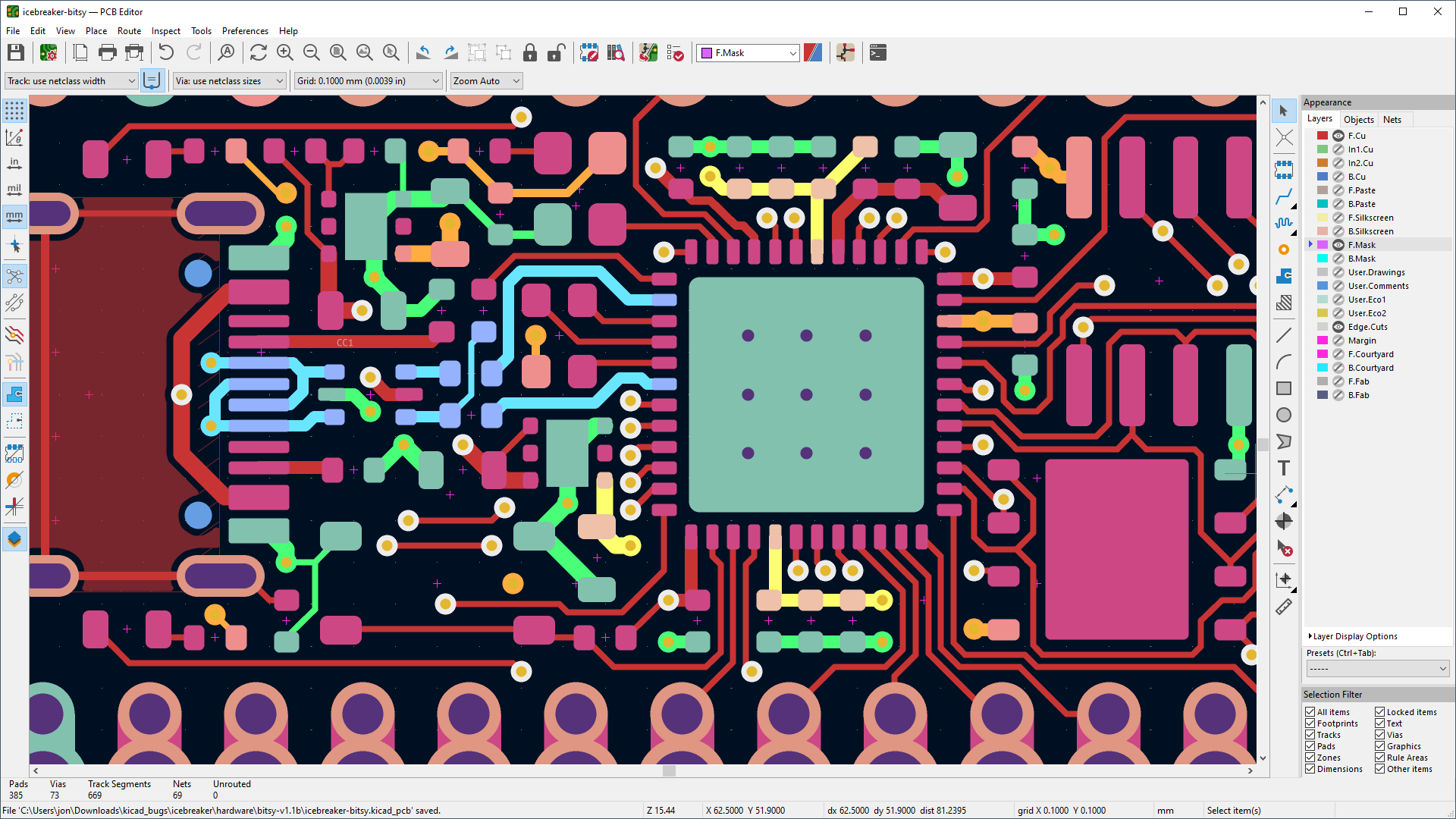

Choosing the Right PCB Design Software

For hobbyists and beginners, user-friendly PCB design software is key. Look for tools that offer free or affordable versions with features like schematic capture, layout editing, and 3D visualization. These tools often come with libraries of components commonly used in wearables, such as accelerometers, heart rate sensors, and microcontrollers.

Popular options include open-source platforms and cloud-based design tools that allow you to work from anywhere. Focus on software that supports exporting Gerber files, which are the standard format for PCB fabrication. This ensures compatibility when ordering PCBs online.

Key Design Considerations for Wearables

When designing a PCB for wearables, keep these factors in mind:

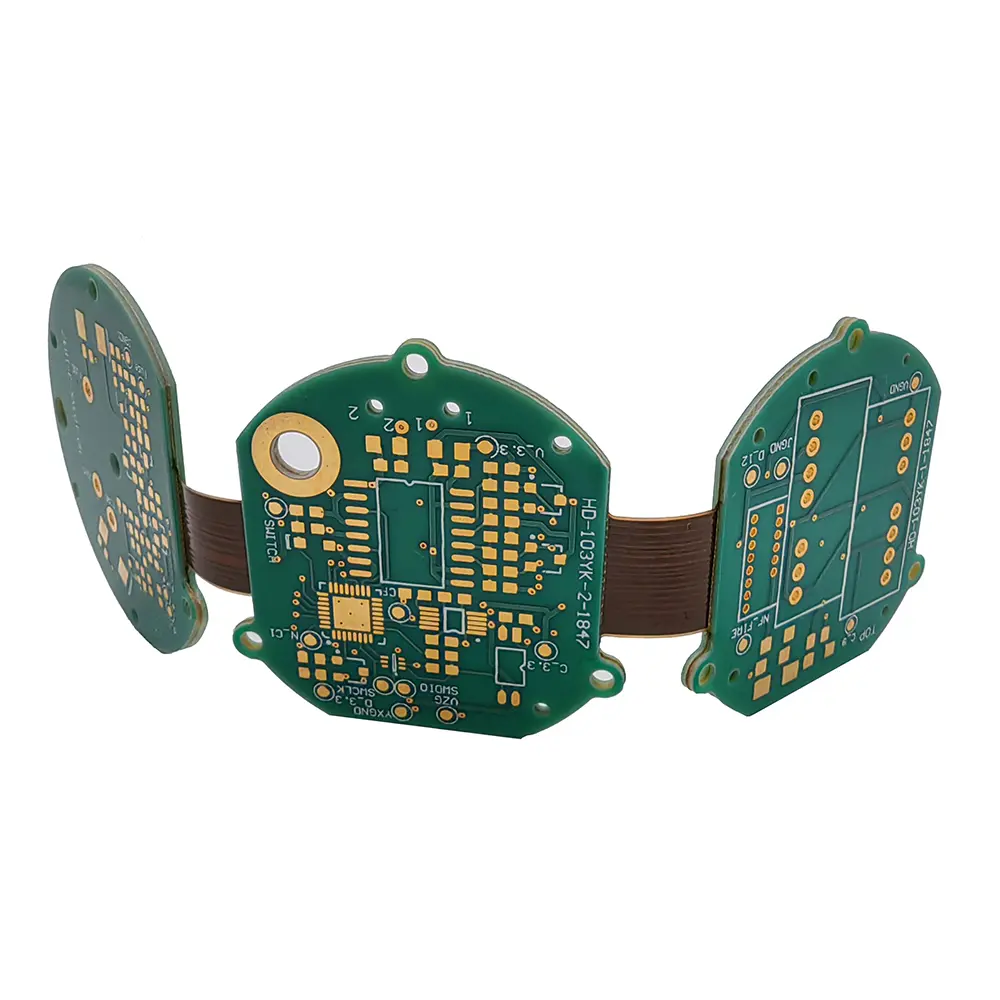

- Size and Shape: Wearables often require non-standard shapes to fit curved or small enclosures. Use flexible or rigid-flex PCBs if your design needs to bend or conform to a specific form. Aim for a compact layout, often under 50mm x 50mm for wrist-worn devices.

- Power Efficiency: Battery life is critical in wearables. Place power-hungry components like processors close to the battery to minimize trace length and reduce power loss. Use low-power components and consider a power management IC to optimize efficiency.

- Signal Integrity: High-frequency signals, like those from Bluetooth or Wi-Fi modules, need careful routing. Maintain a 50-ohm impedance for RF traces and keep them away from noisy components to avoid interference.

- Layer Count: Most wearable PCBs use 2 to 4 layers to balance cost and complexity. A 2-layer board often works for simpler designs, while 4 layers are better for densely packed circuits with multiple ground planes.

Step 2: Learning PCB Layout with Tutorials

If you're new to PCB design, PCB layout tutorials can help you master the basics. These resources often cover schematic creation, component placement, and trace routing—key skills for creating functional boards.

Where to Find PCB Layout Tutorials

Many online platforms offer free tutorials tailored for beginners. Look for video guides or step-by-step articles that focus on designing small-form-factor boards. Topics to prioritize include:

- Creating a schematic with proper connections for sensors and microcontrollers.

- Routing traces to minimize crosstalk, especially for high-speed signals in wearables.

- Placing vias and pads for surface-mount components, which are common in compact designs.

Practice by designing a simple board, like a heart rate monitor with a sensor and LED output. Start with a 2-layer board and aim for a size of 30mm x 30mm to simulate real wearable constraints. Tutorials often provide sample projects to help you learn hands-on.

Common Mistakes to Avoid

Beginners often make errors that can affect PCB performance. Here are pitfalls to watch out for:

- Overcrowding Components: Leave at least 0.2mm spacing between components to avoid soldering issues.

- Ignoring Ground Planes: A solid ground plane reduces noise, especially for analog sensors in wearables. Dedicate an entire layer to ground if possible.

- Poor Trace Widths: Use a trace width of at least 0.25mm for power lines to handle currents up to 1A without overheating.

By following PCB layout tutorials, you can avoid these issues and create a board that’s ready for fabrication.

Step 3: Ordering PCBs Online with Fabrication Services

Once your design is complete, the next step is ordering PCBs online. Online PCB fabrication services streamline the process, offering quick turnaround times and affordable pricing. Here’s how to navigate this step for your wearable project.

How to Choose an Online Fabrication Service

When selecting a service for PCB fabrication, consider these factors:

- Turnaround Time: Wearable projects often require fast prototyping. Look for services offering 24-48 hour quick-turn options for small batches.

- Material Options: For wearables, FR-4 is a common, cost-effective material for rigid boards. If flexibility is needed, ask for polyimide-based flexible PCBs.

- Minimum Order Quantity (MOQ): Many services offer low MOQs, starting at just 5 pieces, which is ideal for prototyping.

- Assembly Services: Some platforms provide PCB assembly, soldering components onto your board. This saves time, especially for tiny surface-mount parts in wearables.

At ALLPCB, we pride ourselves on delivering fast, reliable fabrication tailored to your needs. Upload your Gerber files, select your specifications, and get an instant quote for your wearable PCB project.

Cost-Effective PCB Prototyping Tips

Prototyping can be expensive if not planned carefully. Here are strategies for cost-effective PCB prototyping:

- Optimize Board Size: Smaller boards cost less. Design within a 50mm x 50mm area to keep expenses down—many services charge based on square centimeters.

- Stick to Standard Specifications: Use standard thicknesses (1.6mm for rigid boards) and avoid exotic finishes unless necessary. Standard options are often cheaper.

- Order in Small Batches: Start with 5-10 pieces to test your design. Bulk orders can wait until you’ve finalized the prototype.

- Panelize Designs: If you have multiple small boards, combine them into one panel to reduce fabrication costs. Most services support panelization for free.

For example, a 2-layer PCB of 40mm x 40mm with standard FR-4 material can cost as little as $2 per board for a batch of 10. This makes prototyping accessible even for hobbyists on a tight budget.

Step 4: Testing and Iterating Your Wearable PCB

After receiving your PCBs, testing is crucial to ensure they work as intended. Wearable projects often involve sensitive components like sensors, so thorough validation is key.

Testing Tips for Wearable PCBs

Follow these steps to test your board:

- Visual Inspection: Check for soldering defects or misaligned components. Use a magnifying glass for tiny parts like 0402 resistors.

- Power-Up Test: Connect a power source (e.g., a 3.3V battery) and measure current draw. A fitness tracker PCB should ideally draw under 50mA in active mode.

- Functionality Check: Verify that sensors, LEDs, or communication modules work. For instance, test a heart rate sensor by checking if it outputs a signal between 0.5V and 3V when detecting a pulse.

If issues arise, note them down and revise your design. Online fabrication services make it easy to order a second batch after updates, often within a few days.

Advantages of Using Online PCB Fabrication for Wearables

Ordering PCBs online offers several benefits for wearable projects:

- Accessibility: No need for expensive equipment or local manufacturers. Upload your design and get started from anywhere.

- Speed: Quick-turn services can deliver prototypes in as little as 24 hours, perfect for tight project deadlines.

- Affordability: Low costs for small batches make it feasible for hobbyists and startups to experiment with multiple iterations.

- Customization: Choose from a range of materials, layer counts, and finishes to match the unique needs of your wearable device.

At ALLPCB, we’re committed to supporting your innovation with high-quality manufacturing and assembly services. Whether you’re building a prototype or scaling to production, our platform simplifies every step.

Final Thoughts on Custom PCBs for Wearables

Creating custom PCBs for wearable projects has never been easier thanks to online PCB fabrication services. By using accessible PCB design software for hobbyists, following PCB layout tutorials, and leveraging cost-effective prototyping strategies, you can bring your wearable ideas to life without breaking the bank. Start with a compact design tailored to the constraints of wearables, order a small batch to test, and iterate until your board performs perfectly.

Ready to start your next wearable project? Upload your design files today and experience the ease of ordering PCBs online with ALLPCB. Our fast, reliable services ensure your prototypes are delivered on time and within budget, helping you innovate in the exciting world of wearable technology.

ALLPCB

ALLPCB