Are you struggling to pick the right thyristor or Silicon Controlled Rectifier (SCR) for your high-power application? Don’t worry—selecting the perfect thyristor doesn’t have to be a mystery. In this comprehensive thyristor selection guide, we’ll walk you through the key steps to choose an SCR based on thyristor voltage and current ratings, decode complex datasheets with thyristor datasheet interpretation, and understand critical parameters with clear explanations. Whether you're designing a power converter or a motor control system, this guide will help you make an informed decision. Let’s dive into the details to ensure your project runs smoothly and efficiently.

Why Thyristor Selection Matters for High-Power Applications

Thyristors, commonly known as SCRs, are the backbone of high-power electronics. These semiconductor devices control large amounts of power with precision, making them essential for applications like industrial motor drives, power supplies, and HVAC systems. Choosing the wrong thyristor can lead to system failures, overheating, or inefficient operation. That’s why understanding the thyristor selection guide is crucial for engineers working on high-power designs. A well-selected SCR ensures reliability, reduces downtime, and saves costs in the long run.

What Is a Thyristor (SCR) and How Does It Work?

A thyristor, often referred to as an SCR, is a four-layer semiconductor device with three terminals: anode, cathode, and gate. It acts like a switch that can handle high voltages and currents, turning on when a small signal is applied to the gate and staying on until the current drops below a certain level. This makes SCRs ideal for controlling power in AC and DC circuits. For example, in a 500 kW industrial motor drive, an SCR can manage power delivery by switching on and off at precise intervals.

Understanding how a thyristor works is the first step in selection. It’s a unidirectional device, meaning current flows only in one direction, from anode to cathode. This property is key when designing circuits for applications like rectifiers or inverters. Now, let’s explore how to pick the right one for your needs using a detailed thyristor selection guide.

Key Parameters for Thyristor Selection: A Step-by-Step Guide

When selecting a thyristor for high-power applications, you need to focus on several critical parameters. Let’s break down the most important ones to ensure you make the right choice. This section serves as a practical thyristor selection guide tailored for electrical engineers.

1. Voltage Ratings: Understanding Thyristor Voltage Limits

One of the first things to check in a thyristor datasheet is its voltage rating. The thyristor voltage and current ratings determine whether the device can handle the electrical stress in your system. Key voltage parameters include:

- Peak Repetitive Reverse Voltage (VRRM): This is the maximum reverse voltage the thyristor can withstand without breaking down. For instance, if your system operates at 1200V, choose an SCR with a VRRM of at least 1400V to provide a safety margin.

- Peak Repetitive Forward Voltage (VDRM): This is the maximum forward voltage when the thyristor is off. Similar to VRRM, pick a rating 15-20% higher than your system’s peak voltage.

Selecting a thyristor with insufficient voltage ratings can lead to catastrophic failure. For example, in a 600V DC power supply, using an SCR rated for only 500V could result in breakdown during voltage spikes.

2. Current Ratings: Matching Thyristor to Load Requirements

Next in the thyristor voltage and current ratings checklist is the current rating. Thyristors must handle the load current without overheating. Key current parameters include:

- Average On-State Current (IT(AV)): This is the average current the thyristor can carry continuously. For a 100A load, select an SCR with an IT(AV) of at least 120A to account for variations.

- Surge Current (ITSM): This is the maximum short-term current the thyristor can handle during faults or start-up. If your system might experience a 1000A surge, ensure the SCR’s ITSM exceeds this value.

In a real-world scenario, a welding machine drawing 200A continuously with occasional 500A surges requires an SCR rated for both conditions. Ignoring surge ratings can cause thermal damage over time.

3. Gate Triggering Characteristics: Ensuring Reliable Operation

The gate triggering current (IGT) and voltage (VGT) determine how much signal is needed to turn on the thyristor. For high-power applications, you want an SCR that triggers reliably without requiring excessive gate power. For instance, an IGT of 50mA and VGT of 1.5V are common for industrial SCRs. If your control circuit can’t provide this, you’ll need additional driver circuitry, increasing complexity and cost.

4. Thermal and Power Dissipation Ratings

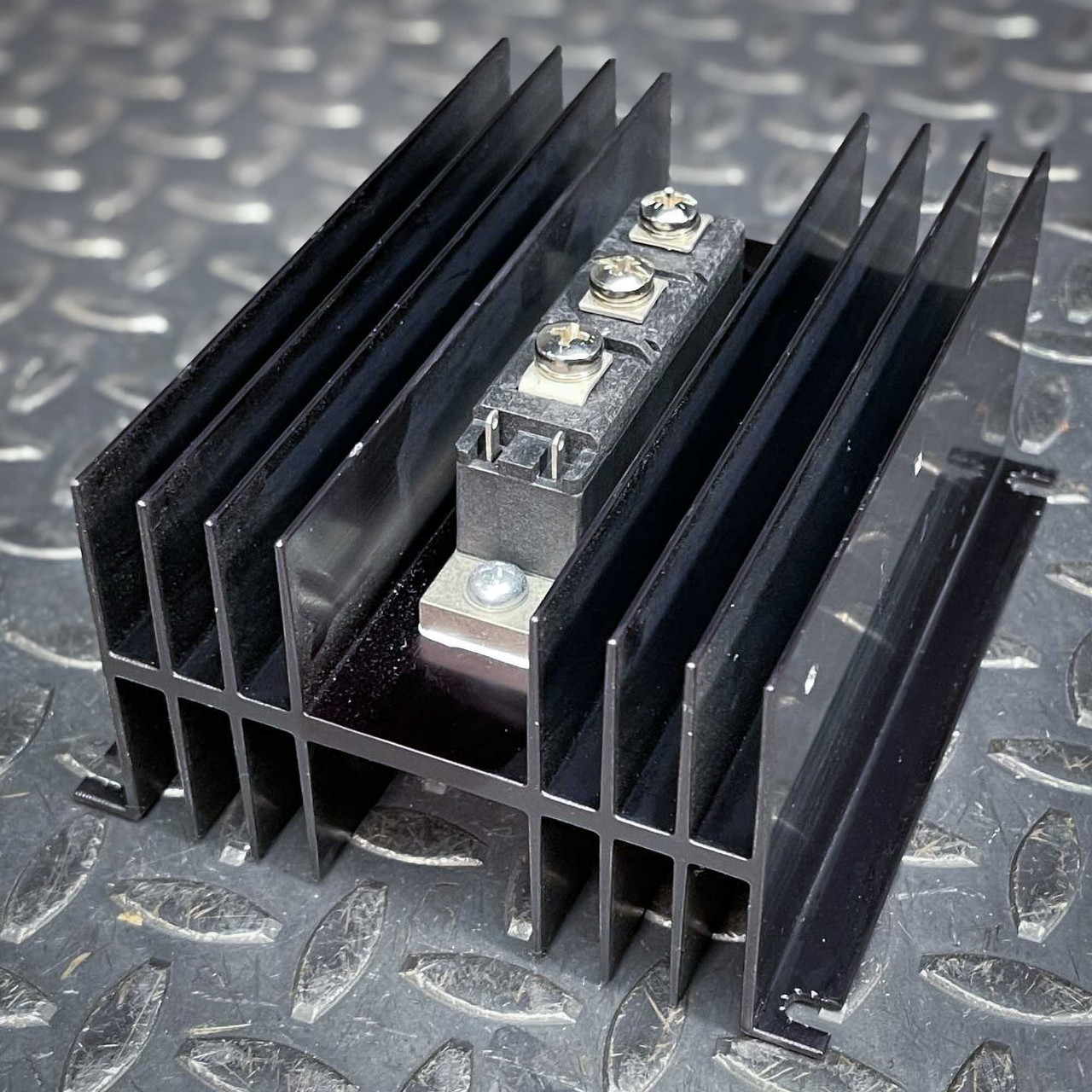

High-power applications generate significant heat, so thermal management is critical. Check the thyristor’s junction temperature (TJ) rating, often around 125°C to 150°C for industrial devices. Also, look at the on-state voltage drop (VTM), which affects power dissipation. For example, an SCR with a VTM of 1.8V at 100A dissipates 180W of heat, requiring adequate cooling like a heatsink rated for at least 200W dissipation.

Thyristor Datasheet Interpretation: Decoding the Numbers

Reading a thyristor datasheet can feel overwhelming, but it’s a vital skill for selection. Let’s break down thyristor datasheet interpretation into simple steps to help you understand the specifications and make informed decisions.

Step 1: Identify Key Electrical Ratings

Start with the headline specs on the first page of the datasheet. Look for VRRM, VDRM, IT(AV), and ITSM. These numbers give you a quick idea if the thyristor suits your voltage and current needs. For example, a datasheet for a Littelfuse SCR might list VRRM as 1600V and IT(AV) as 150A—perfect for a 1000V, 120A system with a safety margin.

Step 2: Check Gate and Triggering Specs

Next, find the gate triggering section. Ensure your control circuit can meet the IGT and VGT requirements. Some datasheets also list the holding current (IH), which is the minimum current needed to keep the thyristor on. If IH is 100mA, your load must maintain at least this current to avoid unintended turn-off.

Step 3: Review Thermal and Mechanical Data

Look for maximum junction temperature (TJ) and thermal resistance (RthJC). These specs help you design cooling solutions. For instance, an RthJC of 0.5°C/W means for every watt dissipated, the junction temperature rises by 0.5°C. If your SCR dissipates 200W, the temperature rise is 100°C, so you’ll need a robust heatsink to keep TJ below 125°C.

Thyristor Comparison Chart: Picking the Best SCR for Your Needs

To simplify selection, let’s look at a thyristor comparison chart with sample devices for high-power applications. This table compares three hypothetical SCRs based on key parameters.

| Parameter | SCR Model A | SCR Model B | SCR Model C |

|---|---|---|---|

| VRRM (V) | 1200 | 1600 | 2000 |

| IT(AV) (A) | 100 | 150 | 200 |

| ITSM (A) | 1000 | 1500 | 2000 |

| IGT (mA) | 50 | 60 | 80 |

| VTM (V) | 1.8 | 2.0 | 2.2 |

From this chart, if your system operates at 1000V and 120A with occasional 1400A surges, Model B is a good fit with its 1600V VRRM and 1500A ITSM. This thyristor comparison chart approach helps narrow down options quickly.

Thyristor Parameters Explained: Deep Dive into Specifications

Let’s take a closer look at thyristor parameters explained to ensure you fully grasp the technical details. Here are additional parameters that often influence selection:

- Critical Rate of Rise of Off-State Voltage (dv/dt): This measures how fast the voltage can change without falsely triggering the thyristor. A typical value is 500V/μs. If your system has rapid voltage changes, choose an SCR with a higher dv/dt rating or add a snubber circuit.

- Turn-Off Time (tq): This is the time it takes for the thyristor to turn off after the current drops. For high-frequency applications, a shorter tq (e.g., 50μs) is better.

- Critical Rate of Rise of On-State Current (di/dt): This indicates how quickly the current can increase without damaging the device. A rating of 100A/μs is common for industrial SCRs. Exceeding this can cause localized heating and failure.

Understanding these parameters ensures your thyristor operates reliably under dynamic conditions. For example, in a 60Hz AC power control system, a slow turn-off time could cause phase control issues, so prioritize a low tq value.

Practical Tips for Thyristor Selection in High-Power Systems

Beyond datasheets and parameters, here are some practical tips from real-world experience to guide your selection process:

- Always Include a Safety Margin: Choose a thyristor with voltage and current ratings at least 20% higher than your system’s maximum. This accounts for spikes and aging.

- Test Under Load Conditions: Before finalizing an SCR, simulate your application’s load in a test setup. I once overlooked surge currents in a motor control project, and the thyristor failed during startup—testing could have prevented this.

- Consult Manufacturer Support: If a datasheet is unclear, reach out to the manufacturer. Many companies like ON Semiconductor or Littelfuse offer application notes and support for high-power designs.

Common Mistakes to Avoid When Selecting Thyristors

Even experienced engineers can make errors during thyristor selection. Here are pitfalls to watch out for:

- Ignoring Thermal Design: Failing to account for heat dissipation can lead to premature failure. Always pair your SCR with an appropriate heatsink.

- Overlooking Gate Drive Requirements: If your control circuit can’t provide the required IGT, the thyristor won’t trigger reliably.

- Choosing Based on Price Alone: A cheaper SCR might not meet your system’s needs, costing more in repairs or downtime. Invest in quality for high-power applications.

Conclusion: Mastering Thyristor Selection for Success

Selecting the right thyristor or SCR for your high-power application is a critical step to ensure system reliability and efficiency. By following this thyristor selection guide, understanding thyristor voltage and current ratings, mastering thyristor datasheet interpretation, using a thyristor comparison chart, and diving into thyristor parameters explained, you’re equipped to make an informed choice. Remember to prioritize safety margins, test under real conditions, and avoid common mistakes like neglecting thermal management.

ALLPCB

ALLPCB