Component tolerance plays a critical role in determining how well a circuit performs. Variations in the values of resistors, capacitors, and other components can lead to unexpected circuit behavior, affecting everything from signal accuracy to power efficiency. In this comprehensive guide, we’ll explore component tolerance effects, circuit performance variations, and dive into specifics like resistor tolerance impact and capacitor tolerance analysis. Whether you're designing precision circuits or troubleshooting unexpected results, understanding precision components and tolerance calculation in electronics is essential for success.

Let’s take a deep dive into how component tolerance influences circuit performance, why it matters, and how you can manage it effectively for optimal results.

What Is Component Tolerance and Why Does It Matter?

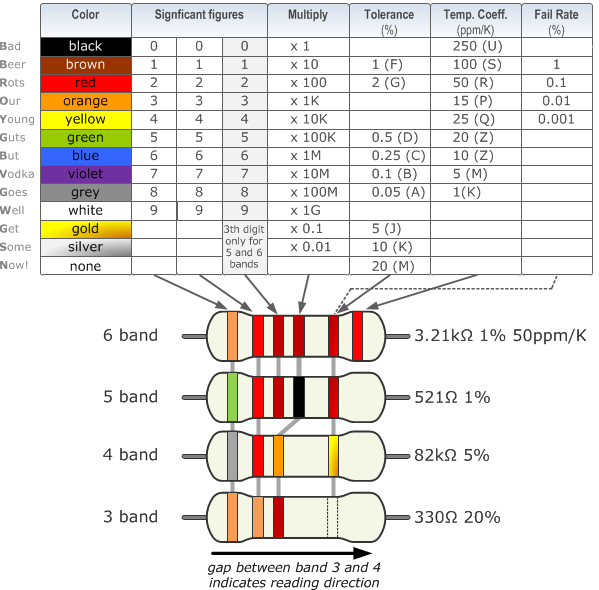

Component tolerance refers to the allowable deviation in a component’s value from its specified or nominal value. For instance, a resistor labeled as 1 kΩ with a 5% tolerance could have an actual resistance anywhere between 950 Ω and 1050 Ω. This variation might seem small, but in sensitive circuits, even minor deviations can cause significant circuit performance variations.

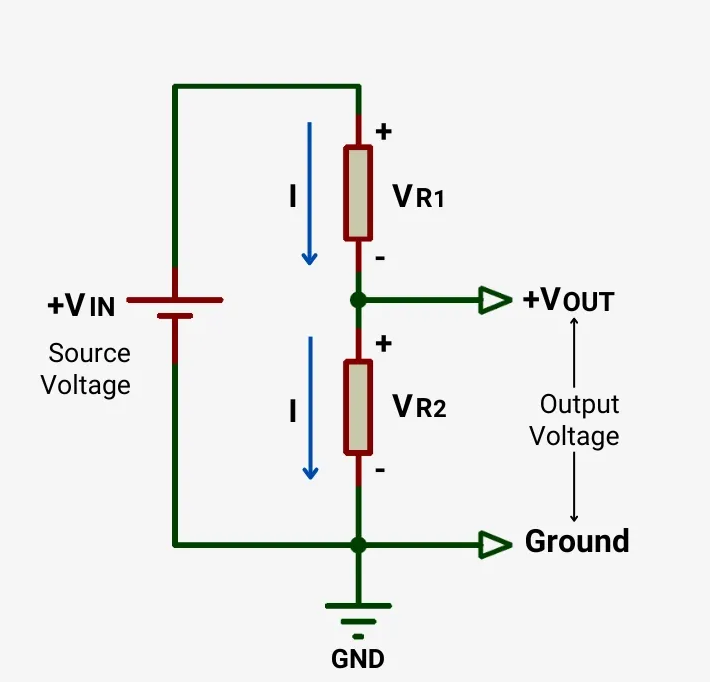

Why does this matter? In electronics, every component interacts with others in the circuit. If one part is off, it can throw off the entire system. For example, in a voltage divider circuit, mismatched resistor values due to tolerance can lead to incorrect output voltages. In high-frequency applications, capacitor tolerance can affect timing and signal integrity. Understanding component tolerance effects helps engineers design more reliable and efficient circuits.

How Component Tolerance Affects Circuit Performance

The impact of component tolerance on circuit performance varies depending on the type of circuit and its application. Below, we break down the key areas where tolerance plays a role and how it leads to circuit performance variations.

1. Signal Accuracy and Precision

In circuits where precision is critical, such as in medical devices or measurement equipment, even a small deviation in component values can lead to inaccurate results. For instance, in an operational amplifier circuit used for signal amplification, a resistor with a 10% tolerance could cause a gain error, leading to incorrect output signals. Using precision components with tighter tolerances (like 1% or 0.1%) can minimize these errors.

Example: Consider a circuit designed to output a 2.5V signal using a voltage divider with two 10 kΩ resistors. If one resistor has a +5% tolerance (10.5 kΩ) and the other a -5% tolerance (9.5 kΩ), the actual output voltage becomes approximately 2.37V—a 5.2% error. This shows the direct resistor tolerance impact on signal accuracy.

2. Frequency Response in Filters

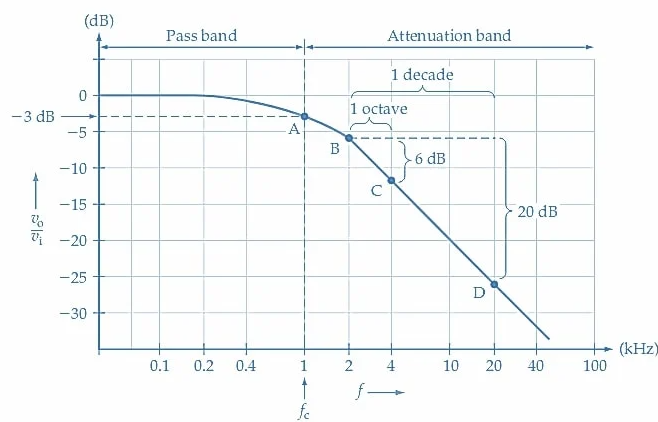

In filter circuits, such as those used in audio processing or radio frequency (RF) applications, component tolerance affects the cutoff frequency and overall frequency response. Capacitors and resistors in these circuits must work together to filter specific frequencies. If a capacitor’s value deviates due to tolerance, the filter might allow unwanted frequencies to pass through or block desired ones.

Numerical Insight: For a simple RC low-pass filter with a nominal cutoff frequency of 1 kHz (using a 1 kΩ resistor and a 159 nF capacitor), a 10% tolerance on the capacitor could shift the cutoff frequency to as low as 909 Hz or as high as 1.11 kHz. This demonstrates the importance of capacitor tolerance analysis in maintaining circuit performance.

3. Power Consumption and Efficiency

Component tolerance can also influence power consumption. In power supply circuits, for example, a resistor with a higher-than-expected value due to tolerance might reduce current flow, impacting the circuit’s efficiency. Conversely, a lower-than-expected value could increase current, leading to overheating or component failure.

4. Timing and Oscillations

In timing circuits, such as oscillators or clock generators, component tolerance directly affects the frequency and stability of the output signal. Capacitors and resistors often determine the timing characteristics in these designs. A deviation in their values can cause the circuit to operate at the wrong frequency, leading to timing errors in digital systems.

Breaking Down Resistor Tolerance Impact

Resistors are fundamental to almost every circuit, and their tolerance can significantly affect performance. The resistor tolerance impact is most noticeable in circuits where precise voltage or current levels are required.

Real-World Scenario: In a current-sensing circuit using a shunt resistor, a 1% tolerance on a 0.1 Ω resistor means the actual resistance could be between 0.099 Ω and 0.101 Ω. If the circuit is designed to measure a 1A current with an expected voltage drop of 0.1V, the actual voltage drop could vary by 1 mV, leading to a measurement error of 1%. For high-precision applications, this error could be unacceptable, requiring precision components with tolerances as low as 0.01%.

When selecting resistors, always consider the tolerance rating and how it aligns with the circuit’s requirements. Standard resistors often come with 5% or 10% tolerance, while precision resistors offer 1% or better. Balancing cost and performance is key—using high-precision resistors everywhere might be overkill and increase expenses unnecessarily.

Capacitor Tolerance Analysis: Why It’s Crucial

Capacitors store and release energy, control timing, and filter signals in circuits. Their tolerance can vary widely, from 5% to as high as 50% in some ceramic types, making capacitor tolerance analysis a vital part of circuit design.

Capacitor tolerance affects several circuit parameters:

- Timing Circuits: In a 555 timer circuit, a capacitor’s value determines the oscillation frequency. A 20% tolerance on a 10 μF capacitor could result in a frequency deviation of up to 20%, disrupting the intended operation.

- Filter Design: As mentioned earlier, capacitor tolerance shifts the cutoff frequency in filters, affecting signal quality.

- Decoupling: In power supply circuits, capacitors stabilize voltage. Tolerance variations can lead to inadequate noise suppression, causing circuit instability.

To mitigate these issues, designers often choose capacitors with tighter tolerances (like 5% or 10%) for critical applications. Additionally, temperature and voltage ratings can influence a capacitor’s actual value, so these factors should be considered alongside tolerance.

The Role of Precision Components in High-Stakes Designs

In applications where accuracy is non-negotiable, such as aerospace, automotive, or medical electronics, precision components are a must. These components have extremely tight tolerances—often 0.1% or better—and are manufactured to minimize variations.

While precision components reduce circuit performance variations, they come at a higher cost. Engineers must weigh the benefits against the budget. For instance, in a consumer-grade audio amplifier, a 5% tolerance resistor might be sufficient, but in a heart rate monitor, a 0.1% tolerance resistor ensures life-saving accuracy.

Tolerance Calculation in Electronics: How to Predict Variations

Understanding and predicting the impact of tolerance requires tolerance calculation in electronics. There are two primary methods to analyze how component variations affect a circuit: worst-case analysis and statistical analysis.

1. Worst-Case Analysis

This method assumes that every component in the circuit is at the extreme end of its tolerance range. For example, in a circuit with three 1 kΩ resistors, each with a 5% tolerance, worst-case analysis considers scenarios where all resistors are at 950 Ω or all at 1050 Ω. This approach ensures the design will function under the most extreme conditions but can lead to over-engineering and higher costs.

2. Statistical Analysis (Monte Carlo Simulation)

A more realistic approach, statistical analysis uses tools like Monte Carlo simulations to predict performance based on random variations within tolerance ranges. By running thousands of simulations, designers can see the probable spread of circuit behavior. For instance, in a filter circuit, a Monte Carlo simulation might show that 95% of manufactured units have a cutoff frequency within ±2% of the target value, even with 5% tolerance components.

Both methods help engineers make informed decisions about component selection and circuit design, minimizing the risk of failure due to component tolerance effects.

Practical Tips for Managing Component Tolerance in Circuit Design

While component tolerance is inevitable, there are ways to manage its impact on circuit performance. Here are some actionable strategies:

- Select Appropriate Tolerances: Use tighter tolerances only where necessary to balance cost and performance. For non-critical parts of the circuit, standard tolerances (5-10%) are often sufficient.

- Design with Margin: Build some flexibility into your design to accommodate variations. For example, if a circuit requires a minimum voltage of 3.3V, design for a slightly higher value to account for tolerance-induced drops.

- Use Simulation Tools: Leverage software to simulate how tolerance affects your circuit. This can save time and resources during prototyping.

- Test and Validate: After assembling your circuit, measure key parameters to ensure they align with design expectations. Adjust trimmer resistors or capacitors if needed.

- Consider Temperature and Aging: Component values can drift over time or with temperature changes. Factor these into your tolerance calculations for long-term reliability.

Conclusion: Mastering Component Tolerance for Better Circuit Performance

Component tolerance is a fundamental aspect of electronics design that directly influences circuit performance variations. Whether it’s the resistor tolerance impact on voltage levels or the nuances of capacitor tolerance analysis in timing circuits, understanding and managing tolerance is key to creating reliable and efficient designs. By using precision components when needed and applying techniques like tolerance calculation in electronics, engineers can minimize errors and ensure consistent performance.

At ALLPCB, we’re committed to supporting your design journey with high-quality components and manufacturing services tailored to your needs. By paying attention to component tolerance and its effects, you can build circuits that not only meet but exceed expectations. Keep these principles in mind during your next project, and watch your designs come to life with unparalleled accuracy and reliability.

ALLPCB

ALLPCB