In the fast-evolving world of electronics, creating compact, efficient, and reliable printed circuit boards (PCBs) is more important than ever. For engineers and manufacturers working on high-density designs, surface mount technology clips (SMT clips) have emerged as a game-changer. These tiny components are transforming SMT PCB assembly by enabling secure mounting, reducing space, and supporting automation. But what exactly are SMT clips, and how do they improve high-density PCB mounting? In this blog, we’ll dive deep into their role, benefits, and applications, providing actionable insights for your next project.

What Are SMT Clips and Why Do They Matter?

SMT clips are small, specialized metal components used in surface mount technology to secure parts or connect PCBs without the need for traditional through-hole methods. Unlike older mounting techniques that require drilling holes through the board, SMT clips are soldered directly onto the PCB surface, aligning perfectly with the principles of SMT PCB assembly. They are often used for connecting modules, grounding, or even as test points in high-density designs.

These clips matter because they address key challenges in modern electronics: space constraints and assembly efficiency. As devices get smaller—think smartphones, wearables, and IoT gadgets—engineers need solutions for high-density PCB mounting. SMT clips offer a small footprint, allowing more components to fit on a single board while maintaining reliability. Their compatibility with automated PCB clip placement also speeds up production, cutting down on manual labor and errors.

The Role of SMT Clips in High-Density PCB Designs

High-density PCB designs pack a large number of components into a limited space, often requiring intricate layouts and precise assembly. SMT clips play a critical role in these designs by providing secure connections without taking up much room. For instance, in a typical smartphone PCB, where space is at a premium, small footprint PCB clips can be used to connect RF shields or ground planes, ensuring signal integrity without adding bulk.

One key advantage of SMT clips in high-density PCB mounting is their ability to handle high-frequency signals. In designs operating at frequencies above 1 GHz, maintaining low impedance is crucial. SMT clips, when properly designed, can offer impedance values as low as 0.1 ohms, minimizing signal loss. This makes them ideal for applications like 5G modules or high-speed data transfer systems.

Additionally, SMT clips support multi-layer PCB designs. They can be placed on both sides of the board, allowing for even denser layouts. This flexibility is a must for industries like automotive electronics, where control units often require hundreds of connections in a compact form factor.

Benefits of Using SMT Clips in PCB Assembly

Integrating surface mount technology clips into your PCB assembly process offers several benefits, especially for high-density and automated workflows. Let’s break down the most impactful advantages:

1. Space Efficiency with Small Footprint PCB Clips

The compact size of small footprint PCB clips is a major plus. Traditional connectors or mounting hardware can take up valuable board space, but SMT clips are often less than 2 mm in height and width. This allows engineers to maximize component density, fitting more functionality into smaller devices.

2. Compatibility with Automated PCB Clip Placement

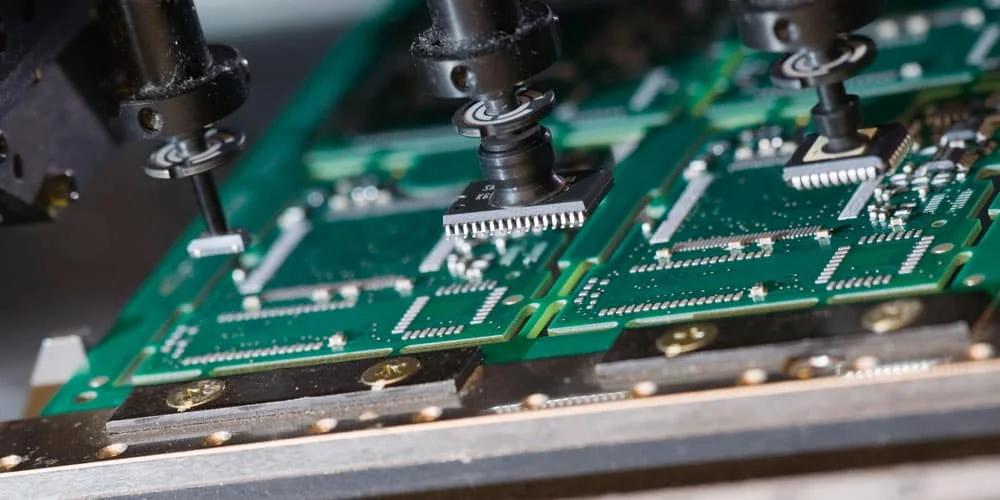

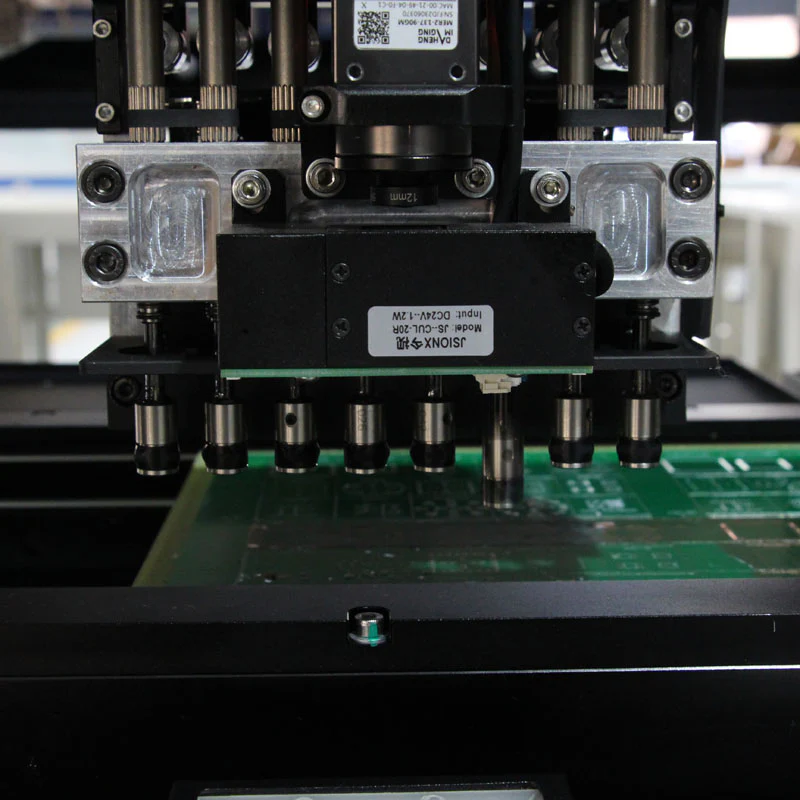

Automation is the backbone of modern PCB manufacturing, and SMT clips are designed for automated PCB clip placement. Pick-and-place machines can position these clips with precision down to 0.01 mm, ensuring consistent assembly even at high volumes. This reduces production time and human error, with some machines capable of placing over 100,000 components per hour.

3. Enhanced Reliability for High-Density Designs

In high-density PCB mounting, maintaining connection stability is critical. SMT clips provide strong mechanical and electrical connections, often withstanding vibrations up to 10 G in rugged applications like industrial equipment. Their surface-mount nature also reduces the risk of damage during assembly compared to through-hole components.

4. Cost-Effective Production

By supporting automation and reducing the need for manual intervention, SMT clips help lower manufacturing costs. Their small size also means less material is used, which can save on expenses over large production runs. For example, switching to SMT clips in a batch of 10,000 units could reduce assembly time by up to 20%, depending on the complexity of the design.

How SMT Clips Enhance SMT PCB Assembly Processes

The SMT PCB assembly process involves several steps, from solder paste application to component placement and reflow soldering. SMT clips integrate seamlessly into this workflow, enhancing efficiency at every stage. Here’s how they contribute:

Solder Paste Printing: SMT clips are compatible with standard stencil printing processes. Their flat contact surfaces ensure even solder distribution, reducing the risk of voids or weak joints.

Component Placement: Thanks to their standardized shapes, SMT clips are easily recognized by vision systems in pick-and-place machines. This allows for precise automated PCB clip placement, even on boards with tight tolerances of less than 0.5 mm between components.

Reflow Soldering: During reflow, SMT clips bond reliably to the PCB surface. Their materials, often copper or stainless steel with a tin finish, are chosen for excellent solderability, ensuring joints that can handle thermal cycling between -40°C and 85°C without cracking.

Inspection and Testing: SMT clips can double as test points, simplifying quality control. Their accessible design allows for quick probing during automated optical inspection (AOI), ensuring defects are caught early.

Applications of SMT Clips in Modern Electronics

The versatility of surface mount technology clips makes them suitable for a wide range of industries. Here are some key areas where they shine:

Consumer Electronics: From smartphones to smartwatches, consumer devices rely on compact, high-density PCBs. SMT clips are used to secure battery connections, RF shields, and grounding points, supporting designs with board densities exceeding 100 components per square inch.

Automotive Systems: Modern vehicles are packed with electronics for infotainment, safety, and engine control. SMT clips provide reliable connections in harsh environments, enduring temperatures up to 125°C and vibrations from uneven terrain.

Medical Devices: In medical equipment like portable monitors or hearing aids, space is critical. Small footprint PCB clips enable miniaturized designs while maintaining the precision needed for life-saving technology.

Industrial IoT: Industrial sensors and controllers often operate in tough conditions. SMT clips ensure stable connections for data transmission, supporting signal speeds up to 10 Gbps in some IoT applications.

Choosing the Right SMT Clips for Your Project

Not all SMT clips are created equal, and selecting the right ones for your SMT PCB assembly requires careful consideration. Here are some factors to keep in mind:

Material and Finish: Look for clips made from durable materials like beryllium copper or stainless steel, with finishes like tin or gold plating for better conductivity and corrosion resistance. Gold-plated clips, for instance, can maintain contact resistance below 10 milliohms over thousands of cycles.

Size and Footprint: Match the clip size to your board’s layout. For ultra-compact designs, opt for small footprint PCB clips with dimensions under 1.5 mm x 1.5 mm to save space.

Current and Voltage Ratings: Ensure the clips can handle your application’s electrical requirements. Some SMT clips are rated for currents up to 3 A and voltages up to 50 V, making them suitable for power connections in small devices.

Compatibility with Automation: Confirm that the clips are supplied in tape-and-reel packaging for seamless integration with automated PCB clip placement systems. This is especially important for high-volume production.

Challenges and Solutions in Using SMT Clips

While SMT clips offer many advantages, there are challenges to consider in high-density PCB mounting. One common issue is thermal stress during reflow soldering, which can cause misalignment if the PCB design doesn’t account for thermal expansion. To mitigate this, use clips with a coefficient of thermal expansion (CTE) close to that of the PCB material, typically around 17 ppm/°C for FR-4 boards.

Another challenge is ensuring consistent solder joint quality in densely packed layouts. Fine-pitch components near SMT clips can lead to solder bridging. Using a stencil with optimized aperture designs and high-quality solder paste with a particle size of Type 4 or smaller can minimize this risk.

Finally, inspecting SMT clips in high-density designs can be tricky due to their small size. Advanced AOI systems with resolutions down to 5 micrometers can help detect defects like insufficient solder or misalignment, ensuring quality control.

Future Trends: SMT Clips and Beyond

The future of surface mount technology clips looks promising as electronics continue to shrink and performance demands grow. Emerging trends include the development of ultra-miniature clips for next-generation 5G and IoT devices, with footprints as small as 0.8 mm x 0.8 mm. Additionally, advancements in materials science are leading to clips with higher thermal and electrical conductivity, supporting applications with power densities exceeding 10 W per square inch.

Automation will also play a bigger role, with AI-driven pick-and-place systems improving the accuracy of automated PCB clip placement. These systems can adapt to varying board layouts in real-time, reducing setup times by up to 30% and paving the way for even faster production cycles.

Conclusion: Why SMT Clips Are the Future of PCB Assembly

In the world of electronics manufacturing, SMT clips are revolutionizing how we approach SMT PCB assembly and high-density PCB mounting. Their small size, compatibility with automated PCB clip placement, and ability to support compact, reliable designs make them indispensable for modern applications. Whether you’re working on consumer gadgets, automotive systems, or industrial IoT solutions, small footprint PCB clips offer a practical way to meet the challenges of miniaturization and performance.

By understanding their benefits, applications, and best practices, you can leverage SMT clips to optimize your PCB designs and streamline production. As technology advances, these tiny components will continue to play a big role in shaping the future of electronics, proving that sometimes, the smallest innovations have the greatest impact.

ALLPCB

ALLPCB