In the fast-paced world of consumer electronics, Mixed Technology PCBs (Printed Circuit Boards) are at the heart of innovation. These boards combine different types of components, such as surface-mount devices (SMDs) and through-hole components, on a single board to meet the complex demands of modern devices like smartphones, wearables, and smart home gadgets. But what makes Mixed Technology PCBs so vital, and what challenges do they pose in design and manufacturing? More importantly, how can these challenges be solved using advanced Electronics PCB technology and innovative solutions for PCB electronics? In this blog, we’ll dive deep into the intricacies of Mixed Technology PCBs, explore the hurdles faced in consumer electronics, and provide practical solutions to overcome them.

What Are Mixed Technology PCBs and Why Are They Important?

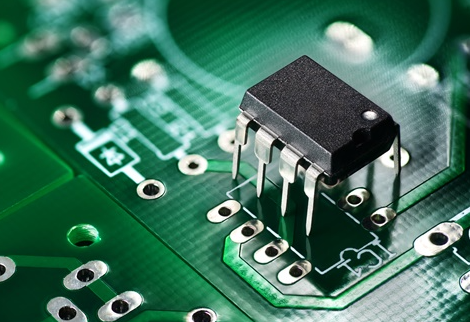

Mixed Technology PCBs are circuit boards that integrate both surface-mount technology (SMT) and through-hole technology (THT) components. SMT components are smaller and mounted directly onto the board’s surface, while THT components are inserted into drilled holes and soldered on the opposite side. This combination allows for greater flexibility in design, accommodating a wide range of components needed for compact and high-performance consumer electronics.

In devices like smartphones or wireless earbuds, space is limited, and performance is critical. Mixed Technology PCBs enable designers to pack more functionality into smaller spaces by using SMT for miniature components like resistors and capacitors, while relying on THT for larger, high-power components like connectors or transformers. This hybrid approach is a cornerstone of modern Electronics PCB technology, driving innovation in consumer products.

Key Challenges in Using Mixed Technology PCBs for Consumer Electronics

While Mixed Technology PCBs offer significant advantages, they also come with unique challenges during design, assembly, and testing. Below, we break down the primary obstacles faced in consumer electronics and explain why they matter.

1. Design Complexity and Space Constraints

Consumer electronics are all about miniaturization. Devices must be sleek and compact, which puts immense pressure on PCB designers to fit diverse components into tight spaces. Mixing SMT and THT components complicates the layout, as each type has different mounting and soldering requirements. For instance, SMT components require precise placement to avoid misalignment, while THT components need drilled holes, which take up additional board space.

This complexity can lead to signal integrity issues if not managed properly. High-frequency signals in devices like smartwatches can experience interference if traces are not optimized for impedance, often requiring values around 50 ohms for controlled impedance designs. Without careful planning, crosstalk and noise can degrade performance.

2. Manufacturing and Assembly Difficulties

The assembly process for Mixed Technology PCBs is more intricate than for single-technology boards. SMT components are typically placed and soldered using automated reflow soldering, while THT components often require manual insertion or wave soldering. Coordinating these processes increases production time and the risk of errors, such as cold solder joints or component damage due to thermal stress.

For example, during reflow soldering, temperatures can reach up to 260°C, which might affect nearby THT components if not shielded properly. This dual-process nature makes achieving consistent quality a significant challenge in high-volume consumer electronics manufacturing.

3. Thermal Management Issues

Consumer electronics often generate significant heat due to high-power components and compact designs. Mixed Technology PCBs can struggle with thermal dissipation because SMT and THT components have different heat tolerances and dissipation characteristics. Without proper heat management, components can overheat, leading to failures or reduced lifespan.

In a typical gaming controller, for instance, power-intensive THT connectors might reach temperatures of 85°C or higher during operation, while nearby SMT chips are rated for lower thresholds. This mismatch can create hotspots on the board, impacting reliability.

4. Testing and Quality Assurance

Ensuring the functionality of a Mixed Technology PCB is no easy task. The combination of SMT and THT components means that testing must account for different failure modes. Automated optical inspection (AOI) works well for SMT components, but THT solder joints often require manual inspection or X-ray analysis to detect hidden defects. This adds to the cost and time of quality assurance, especially for consumer electronics where reliability is non-negotiable.

Solutions for Overcoming Mixed Technology PCB Challenges

Despite these challenges, advancements in Electronics PCB technology and innovative solutions for PCB electronics have made it possible to address these issues effectively. Here are actionable strategies to ensure success with Mixed Technology PCBs in consumer electronics.

1. Advanced Design Tools for Optimized Layouts

Modern PCB design software offers powerful tools to manage the complexity of Mixed Technology boards. Features like 3D modeling and simulation allow designers to visualize component placement and identify potential conflicts before manufacturing. For instance, impedance calculators can help maintain signal integrity by ensuring trace widths and spacing meet specific requirements, such as maintaining a 50-ohm impedance for high-speed signals in a wearable device.

Additionally, design rule checks (DRC) can flag issues like insufficient clearance between SMT and THT components, reducing errors early in the process. By leveraging these tools, designers can create compact layouts that balance performance and space constraints.

2. Streamlined Manufacturing Processes

To tackle assembly challenges, manufacturers can adopt hybrid soldering techniques that combine reflow and selective wave soldering. Selective soldering targets specific THT areas without exposing SMT components to unnecessary heat, reducing thermal stress. For high-volume production, investing in automated pick-and-place machines with dual capabilities for SMT and THT can improve precision and speed, cutting down on manual labor.

Moreover, using lead-free solder alloys with lower melting points (around 217°C) can minimize heat-related damage during assembly, ensuring both types of components are soldered effectively without compromising quality.

3. Effective Thermal Management Strategies

Thermal issues can be mitigated by incorporating heat dissipation features into the PCB design. Adding thermal vias—small holes filled with conductive material—near high-power components can transfer heat away from critical areas. For example, placing thermal vias under a THT power connector can reduce its operating temperature by up to 10-15°C, depending on the board’s copper thickness (typically 1-2 oz).

Using materials with higher thermal conductivity, such as aluminum-backed PCBs for LED lighting in consumer devices, can also enhance heat dissipation. Additionally, strategic placement of components—keeping heat-sensitive SMT parts away from high-power THT elements—further prevents thermal hotspots.

4. Comprehensive Testing Protocols

To ensure quality, a multi-layered testing approach is essential for Mixed Technology PCBs. Combining AOI for SMT components with X-ray inspection for THT solder joints provides thorough defect detection. In-circuit testing (ICT) can also verify electrical functionality by checking for shorts or open circuits, especially in dense consumer electronics boards.

For high-reliability applications, environmental stress testing—exposing the PCB to temperature cycles between -40°C and 85°C—can simulate real-world conditions and identify potential failures before products reach the market. These rigorous protocols help maintain the high standards expected in consumer electronics.

Future Trends in Mixed Technology PCBs for Consumer Electronics

As consumer electronics continue to evolve, so does Electronics PCB technology. Emerging trends are shaping the future of Mixed Technology PCBs, offering new solutions for PCB electronics challenges. Here are a few developments to watch:

- Flexible and Rigid-Flex PCBs: Combining flexibility with Mixed Technology allows for even more compact designs in wearables and foldable devices. These boards can bend without breaking, accommodating both SMT and THT components in unconventional shapes.

- Advanced Materials: New substrates with better thermal and electrical properties are being developed to handle the demands of 5G devices and IoT gadgets, reducing signal loss and heat buildup.

- AI-Driven Design: Artificial intelligence is being integrated into PCB design tools to automate layout optimization and predict potential issues, streamlining the development of Mixed Technology boards.

These innovations promise to make Mixed Technology PCBs even more efficient and reliable, ensuring they remain a key component of cutting-edge consumer electronics.

Why Choose Professional Support for Mixed Technology PCBs?

Navigating the complexities of Mixed Technology PCBs requires expertise and precision, especially for consumer electronics where performance and reliability are critical. Partnering with a trusted PCB provider can make all the difference. At ALLPCB, we specialize in delivering tailored solutions for PCB electronics, from design optimization to high-quality manufacturing and testing. Our advanced Electronics PCB technology ensures that your Mixed Technology boards meet the highest industry standards, no matter the challenge.

Whether you’re developing the next big smartphone or a smart home device, our team is equipped to handle the intricacies of mixed-component designs, offering end-to-end support to bring your vision to life.

Conclusion: Mastering Mixed Technology PCBs for Consumer Electronics

Mixed Technology PCBs are indispensable in the world of consumer electronics, enabling the creation of compact, powerful, and versatile devices. However, their design and production come with challenges like layout complexity, assembly difficulties, thermal management, and rigorous testing needs. By adopting advanced Electronics PCB technology and implementing practical solutions for PCB electronics, these hurdles can be overcome, ensuring high-quality results.

From leveraging cutting-edge design tools to optimizing manufacturing processes and embracing future trends, the path to mastering Mixed Technology PCBs is clear. With the right strategies and professional support from ALLPCB, you can confidently tackle the demands of consumer electronics and stay ahead in a competitive market. Let’s build the future of electronics together, one innovative PCB at a time.

ALLPCB

ALLPCB