If you're looking for the essential tools for hand-assembling mixed technology printed circuit boards (PCBs), you've come to the right place. Mixed technology PCBs combine Surface Mount Technology (SMT) and Through-Hole Technology (THT), requiring a unique set of tools for precision and efficiency. In this guide, we'll cover the must-have tools for hand assembly of mixed technology PCBs, including equipment for SMT and through-hole components, to help you achieve professional results. Whether you're a hobbyist or a professional engineer, having the right tools can make all the difference in your PCB assembly process.

Below, we'll dive into a detailed breakdown of the tools needed for hand assembly of mixed technology PCBs, focusing on practical solutions and tips for using them effectively. From soldering equipment to inspection tools, we've got you covered with everything you need for a successful build.

What Are Mixed Technology PCBs?

Mixed technology PCBs are circuit boards that incorporate both SMT and through-hole components. SMT components are mounted directly onto the surface of the board, allowing for smaller, more compact designs. Through-hole components, on the other hand, have leads that pass through holes in the board and are soldered on the opposite side, offering greater durability for high-stress applications. Combining these technologies on a single board often provides the best of both worlds—compactness from SMT and reliability from THT.

Hand-assembling these boards requires precision and versatility since you're working with components of varying sizes and mounting techniques. The tools for hand assembly of PCB mixed technology must address the unique challenges of both SMT and through-hole assembly. Let's explore the essential tools you'll need to get the job done right.

Essential Tools for Hand Assembly of Mixed Technology PCBs

Assembling mixed technology PCBs by hand demands a well-equipped workspace. Below, we've categorized the essential tools into different groups based on their function in the assembly process. Each tool is critical for ensuring accuracy, safety, and quality in your PCB projects.

1. Soldering Tools for SMT and Through-Hole Components

Soldering is at the heart of PCB assembly, and mixed technology boards require tools that can handle both fine SMT components and larger through-hole parts. Here are the key soldering tools you’ll need:

- Soldering Iron with Adjustable Temperature: A high-quality soldering iron with adjustable temperature control is a must. For SMT components, you'll need lower temperatures (around 260-300°C) to avoid damaging delicate parts. For through-hole components, higher temperatures (up to 350°C) may be necessary to ensure proper solder flow through the holes. Look for an iron with a fine tip for SMT work and a broader tip option for THT soldering.

- Solder Wire: Use lead-free solder wire with a rosin core for better environmental safety and effective bonding. A diameter of 0.5mm to 0.8mm works well for SMT, while 1.0mm is ideal for through-hole soldering.

- Hot Air Rework Station: For SMT components, especially those with multiple pins like QFN or BGA packages, a hot air rework station is invaluable. It allows you to reflow solder on surface-mounted parts without direct contact, preventing damage to the board or components.

- Desoldering Tools: Mistakes happen, and desoldering tools like a solder sucker or desoldering braid (wick) are essential for removing excess solder or correcting errors. A desoldering pump is particularly useful for through-hole components, while braid works well for SMT pads.

2. Precision Tools for Component Placement

Placing components accurately on a mixed technology PCB is crucial, especially for tiny SMT parts. These precision tools will help you handle components with care and accuracy:

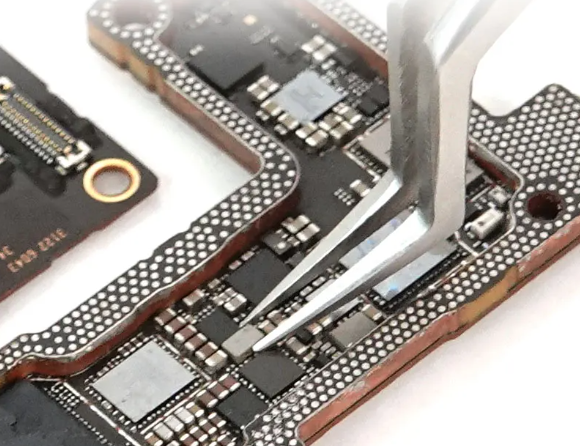

- Tweezers: Anti-static, fine-tip tweezers are essential for picking and placing SMT components. Look for tweezers with a non-magnetic stainless steel tip to avoid interference with sensitive electronics. A curved tip can be helpful for accessing tight spaces.

- Component Alignment Tools: For fine-pitch SMT components, a small alignment tool or dental pick can assist in nudging parts into place before soldering. This ensures proper alignment with the PCB pads, reducing the risk of shorts or misplacement.

- Needle-Nose Pliers: For through-hole components, needle-nose pliers are useful for bending leads and holding parts in place during soldering. Choose a pair with a comfortable grip for extended use.

3. Cutting and Trimming Tools for Through-Hole Assembly

Through-hole components often require lead trimming after soldering, and having the right cutting tools ensures a clean finish without damaging the board.

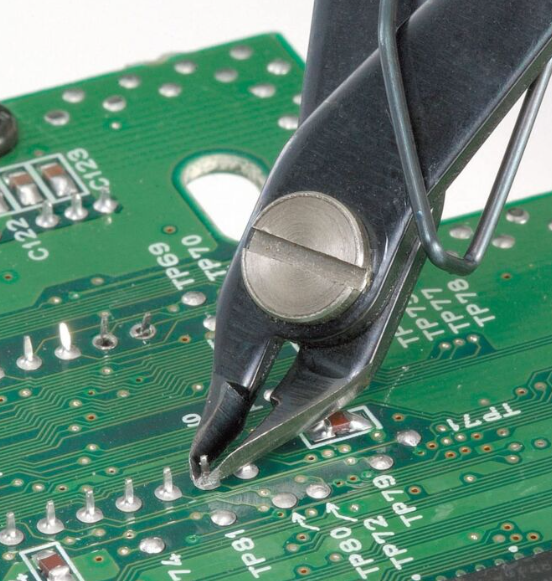

- Flush Cutters: These are small, sharp cutters designed to trim excess leads from through-hole components close to the board. A good pair of flush cutters will leave a smooth cut, reducing the risk of sharp edges that could cause injury or short circuits.

- Wire Strippers: If you're working with through-hole components that require additional wiring, a wire stripper is handy for preparing leads or connecting cables to the board.

4. Inspection and Testing Tools

After assembling a mixed technology PCB, thorough inspection and testing are necessary to ensure functionality and quality. These tools help identify issues before powering up the board.

- Magnifying Glass or Microscope: A magnifying glass or a desktop microscope with at least 10x magnification is essential for inspecting solder joints on SMT components. This helps detect cold solder joints, bridges, or insufficient solder that could cause failures.

- Multimeter: A digital multimeter is critical for testing continuity, voltage, and resistance on the assembled PCB. Use it to check for shorts between pads or verify that components are correctly connected. For example, you can measure resistance across a resistor to ensure it matches the specified value (e.g., 1kΩ ±5%).

- ESD-Safe Wrist Strap: Electrostatic discharge (ESD) can damage sensitive components, especially SMT parts. An ESD-safe wrist strap grounded to your workspace prevents static buildup, protecting your board during inspection and assembly.

5. Workspace and Safety Equipment

A well-organized and safe workspace is just as important as the tools themselves. Here are some essentials to keep your assembly process smooth and hazard-free.

- ESD-Safe Mat: Place an ESD-safe mat on your workbench to provide a static-free surface for assembling mixed technology PCBs. Pair it with your wrist strap for maximum protection.

- Soldering Fume Extractor: Soldering produces fumes that can be harmful if inhaled over time. A fume extractor or fan with a carbon filter keeps your workspace safe by removing these fumes.

- Good Lighting: Bright, focused lighting is necessary for working with small SMT components. A desk lamp with adjustable brightness or a ring light around a magnifying lens can make a big difference in visibility.

Tips for Using Tools in Mixed Technology PCB Assembly

Having the right tools for hand assembly of PCB mixed technology is only half the battle. Knowing how to use them effectively ensures high-quality results. Here are some practical tips to keep in mind:

- Start with SMT Components: When assembling a mixed technology PCB, place and solder SMT components first. Their smaller size and surface mounting make them more delicate, and soldering them before through-hole parts prevents accidental damage from handling larger components later.

- Use Proper Soldering Techniques: For SMT, apply a small amount of solder to one pad, place the component, and reflow the solder to secure it before soldering the remaining pads. For through-hole, insert the component, bend the leads slightly to hold it in place, and solder each lead with a clean, conical joint.

- Avoid Overheating: SMT components are sensitive to heat. Limit soldering time to 2-3 seconds per pad to prevent thermal damage. For through-hole parts, ensure the solder flows through the hole completely, indicating a good connection without excessive heat exposure.

- Keep Your Workspace Clean: Regularly clean your tools and workspace to avoid contamination. Flux residue or debris on the PCB can cause shorts or corrosion over time. Use isopropyl alcohol and a brush to clean the board after soldering.

Challenges in Hand-Assembling Mixed Technology PCBs and How Tools Help

Hand-assembling mixed technology PCBs comes with unique challenges due to the combination of SMT and through-hole components. Here’s how the right tools can help overcome these obstacles:

- Component Size Disparity: SMT components can be as small as 0.4mm x 0.2mm (0402 package), while through-hole parts are much larger. Precision tools like fine-tip tweezers and magnifying glasses make handling tiny SMT parts manageable, while needle-nose pliers assist with larger through-hole leads.

- Soldering Complexity: SMT soldering requires precision to avoid bridges between closely spaced pads (e.g., 0.5mm pitch on fine-pitch ICs). A hot air station and fine-tip soldering iron ensure clean joints. Through-hole soldering, on the other hand, needs proper heat distribution to fill holes, which a higher-powered iron can achieve.

- Risk of Damage: Static electricity or excessive heat can ruin sensitive components. ESD-safe tools and temperature-controlled soldering equipment minimize these risks, protecting your investment in components and boards.

Conclusion

Hand-assembling mixed technology PCBs is a rewarding but challenging task that requires the right set of tools to achieve professional results. From soldering equipment tailored for SMT and through-hole components to precision tools for placement and inspection, each piece of equipment plays a vital role in the process. By investing in high-quality tools for hand assembly of PCB mixed technology, such as adjustable soldering irons, anti-static tweezers, and multimeters, you can ensure accuracy, safety, and reliability in your projects.

Whether you're assembling a prototype or a small batch of boards, having the proper PCB tools for assembly of SMT and through-hole components can save time and reduce errors. Set up your workspace with these essentials, follow best practices, and tackle mixed technology PCB assembly with confidence. With the right preparation and equipment, you're well on your way to creating functional and durable circuit boards for any application.

ALLPCB

ALLPCB