In today’s fast-paced electronics industry, a transparent PCB supply chain is more important than ever. But what exactly does transparency mean in this context, and why should it matter to you? Simply put, a transparent PCB supply chain ensures that every step—from raw material sourcing to final assembly—is visible, traceable, and accountable. This builds trust with customers, improves reliability, and helps meet strict industry standards. Whether you’re an engineer, a manufacturer, or a business owner, understanding component traceability, ethical sourcing in electronics, and supply chain visibility for PCBs can make a significant difference in your projects.

In this blog, we’ll dive deep into the importance of transparency in the PCB supply chain. We’ll explore how it impacts trust and reliability, the role of component traceability, the benefits of ethical sourcing, and ways to enhance supply chain visibility. Let’s get started on this journey to better understand how transparency can elevate your PCB projects.

Why Transparency Matters in the PCB Supply Chain

The PCB (Printed Circuit Board) supply chain is a complex web of suppliers, manufacturers, and distributors. A lack of transparency in this process can lead to delays, quality issues, and even ethical concerns. When every part of the chain is visible, it’s easier to spot problems early, ensure high-quality components, and maintain accountability. A transparent PCB supply chain also helps meet regulatory requirements, especially in industries like aerospace, automotive, and medical devices, where standards are strict.

Transparency isn’t just about avoiding problems—it’s also about building trust. When customers know where their components come from and how they’re made, they feel more confident in the final product. For instance, a study by a leading industry group found that 78% of electronics companies reported improved customer satisfaction after adopting transparent supply chain practices. This shows how much visibility matters in today’s market.

Component Traceability: The Backbone of a Transparent PCB Supply Chain

Component traceability refers to the ability to track every part used in a PCB from its origin to its placement on the board. This is a critical aspect of a transparent PCB supply chain because it ensures accountability at every stage. Traceability helps identify the source of a component, its manufacturing date, and even the batch it came from. If a defect is found, traceability allows manufacturers to quickly pinpoint the issue and recall only the affected products, saving time and money.

For example, imagine a batch of capacitors with a failure rate of 5% due to a manufacturing defect. With proper traceability systems in place, you can trace the faulty components back to their supplier and batch number, preventing widespread issues. Without traceability, you might need to scrap entire production runs, costing thousands of dollars. Traceability systems often use barcodes, RFID tags, or software to log data at each step, ensuring no detail is missed.

Traceability also plays a role in meeting industry standards. Regulations like RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) require detailed records of materials used in electronics. A robust traceability system ensures compliance, avoiding costly fines or legal issues.

Ethical Sourcing in Electronics: A Key to Trust

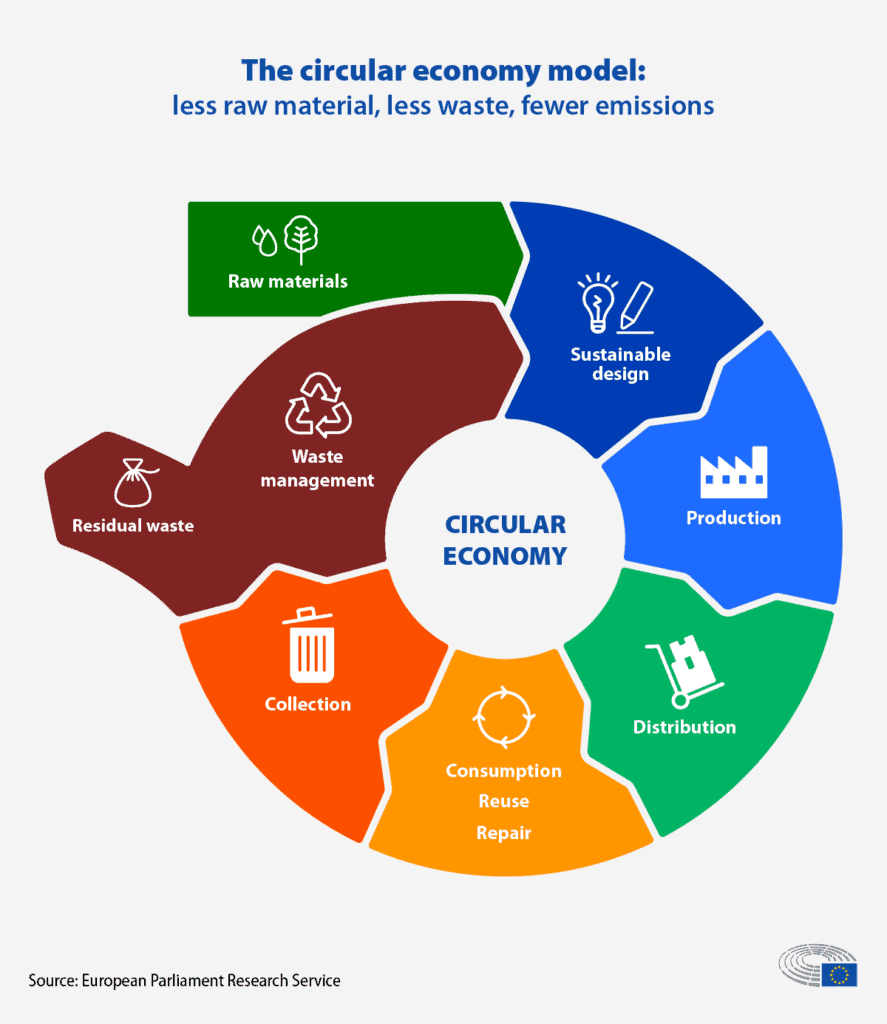

Ethical sourcing in electronics is another pillar of a transparent PCB supply chain. It means ensuring that the materials and components used in PCBs are obtained responsibly, without exploiting workers or harming the environment. This includes avoiding conflict minerals—materials like tin, tantalum, tungsten, and gold sourced from regions with armed conflict or human rights abuses.

Ethical sourcing builds trust with customers who are increasingly concerned about sustainability and social responsibility. A report from a global consulting firm found that 66% of consumers are willing to pay more for products from companies committed to ethical practices. By prioritizing ethical sourcing, companies not only meet customer expectations but also reduce the risk of reputational damage from supply chain scandals.

Implementing ethical sourcing starts with supplier audits and certifications. Working with suppliers who follow international standards, such as those set by the Responsible Business Alliance (RBA), ensures that raw materials are sourced sustainably. Additionally, blockchain technology is emerging as a tool to verify the origin of materials, providing an unchangeable record of a component’s journey through the supply chain.

Supply Chain Visibility for PCBs: Seeing the Full Picture

Supply chain visibility for PCBs means having a clear view of every stage of production, from raw material extraction to final delivery. This level of insight allows companies to monitor progress, identify bottlenecks, and respond quickly to disruptions. With global supply chains often spanning multiple countries, visibility is essential for managing risks like shipping delays or sudden price increases in raw materials.

For instance, during the global chip shortage of 2021, many electronics manufacturers struggled to meet demand due to a lack of visibility into their supply chains. Companies with better visibility were able to pivot quickly, finding alternative suppliers or adjusting production schedules. Tools like real-time tracking software and IoT (Internet of Things) devices can provide live updates on inventory levels, shipping statuses, and production timelines, enhancing supply chain visibility for PCBs.

Visibility also improves quality control. When you can see where a component is at any given time, it’s easier to ensure it meets your specifications. For example, if a batch of resistors is delayed at customs, visibility tools can alert you early, allowing you to source replacements before production stalls. This proactive approach minimizes downtime and keeps projects on track.

The Benefits of a Transparent PCB Supply Chain

Investing in a transparent PCB supply chain offers numerous advantages for manufacturers, engineers, and end customers. Here are some key benefits:

- Improved Quality Control: Transparency allows for better monitoring of components, reducing the risk of defects. For example, knowing the exact impedance value of a batch of resistors (e.g., 50 ohms with a tolerance of ±1%) ensures they meet design requirements before assembly.

- Faster Problem Resolution: With traceability and visibility, issues like component failures can be addressed quickly, minimizing production delays.

- Regulatory Compliance: Transparent practices help meet industry standards, avoiding penalties and ensuring products are safe for use.

- Customer Trust: When customers know your supply chain is ethical and transparent, they’re more likely to choose your products over competitors.

- Cost Savings: By identifying inefficiencies or risks early, transparency reduces waste and prevents costly recalls.

These benefits show why transparency isn’t just a buzzword—it’s a practical strategy for success in the electronics industry.

How to Achieve Transparency in Your PCB Supply Chain

Building a transparent PCB supply chain requires a combination of technology, processes, and partnerships. Here are actionable steps to get started:

- Adopt Traceability Systems: Use barcodes, RFID tags, or software to track components from origin to assembly. Ensure every part has a unique identifier for easy lookup.

- Partner with Ethical Suppliers: Work with suppliers who follow responsible sourcing practices. Conduct regular audits to verify compliance with labor and environmental standards.

- Invest in Visibility Tools: Implement real-time tracking software to monitor inventory, shipments, and production status. IoT devices can provide live data on component locations and conditions.

- Educate Your Team: Train employees on the importance of transparency and how to use traceability and visibility tools effectively.

- Leverage Blockchain Technology: Use blockchain for an unalterable record of material origins and supply chain movements, enhancing trust and accountability.

By taking these steps, you can create a supply chain that’s not only transparent but also reliable and efficient. While the initial investment in tools and training may seem high, the long-term benefits—like reduced costs and improved customer satisfaction—make it worthwhile.

Challenges in Achieving a Transparent PCB Supply Chain

While the benefits of transparency are clear, there are challenges to overcome. One major hurdle is the complexity of global supply chains. With components often sourced from multiple countries, coordinating data and ensuring visibility can be difficult. Additionally, some suppliers may resist sharing detailed information due to privacy or competitive concerns.

Cost is another barrier. Implementing traceability systems and visibility tools requires upfront investment in technology and training. For small businesses, this can strain budgets. However, starting small—perhaps by focusing on traceability for critical components—can help manage costs while still improving transparency.

Finally, data security is a concern. Sharing supply chain information digitally increases the risk of cyberattacks. Using secure platforms and encryption can mitigate this risk, ensuring sensitive data remains protected.

Future Trends in PCB Supply Chain Transparency

The future of PCB supply chain transparency looks promising, thanks to emerging technologies. Artificial Intelligence (AI) and Machine Learning (ML) are being used to predict supply chain disruptions before they happen, analyzing data on weather, shipping delays, and supplier performance. This allows companies to take preventive action, keeping production on schedule.

Blockchain, as mentioned earlier, is also gaining traction. Its ability to create a tamper-proof record of supply chain events makes it ideal for verifying ethical sourcing and component traceability. Additionally, the rise of Industry 4.0—smart factories with interconnected devices—will further enhance supply chain visibility for PCBs by automating data collection and analysis.

Staying ahead of these trends can give your business a competitive edge, ensuring your supply chain remains transparent and reliable in the years to come.

Conclusion: Building a Transparent Future for PCBs

A transparent PCB supply chain is no longer optional—it’s a necessity for building trust and reliability in the electronics industry. By focusing on component traceability, ethical sourcing in electronics, and supply chain visibility for PCBs, companies can improve quality, comply with regulations, and meet customer expectations. While challenges like cost and complexity exist, the benefits of transparency far outweigh the drawbacks.

At ALLPCB, we’re committed to supporting transparency in every step of the PCB manufacturing process. By adopting the strategies and technologies discussed in this blog, you can create a supply chain that’s not only efficient but also trustworthy. Start small, prioritize key areas like traceability, and scale up as your capabilities grow. A transparent supply chain isn’t just good business—it’s the foundation of long-term success.

ALLPCB

ALLPCB