In the fast-paced world of electronics, printed circuit boards (PCBs) are the backbone of nearly every device, from smartphones to medical equipment. For engineers, ensuring a PCB order is successful goes beyond just designing a flawless schematic—it requires seamless collaboration with the manufacturer. This is where customer support plays a pivotal role. Exceptional customer support can make the difference between a smooth, on-time delivery and costly delays or errors. In this blog, we explore how responsive, knowledgeable, and proactive customer support ensures successful PCB orders, offering engineers practical insights to streamline their projects.

From addressing design queries to navigating complex manufacturing requirements, customer support acts as a bridge between an engineer's vision and the final product. Let's dive into the key ways customer support contributes to PCB success and how engineers can leverage it effectively.

Why Customer Support Matters in PCB Manufacturing

PCB manufacturing is a complex process involving multiple stages—design validation, material selection, fabrication, assembly, and testing. Each step presents opportunities for errors, miscommunications, or delays, especially when tight deadlines or intricate designs are involved. According to industry data, up to 30% of PCB prototypes fail due to design or manufacturing issues that could have been caught early with proper communication. Customer support serves as the critical link that ensures these issues are identified and resolved before they escalate.

Effective customer support provides engineers with real-time feedback, technical expertise, and solutions tailored to their project needs. For instance, a common issue like incorrect trace width for a high-speed signal (e.g., requiring 50-ohm impedance for a 5 Gbps signal) can be flagged during design review by a knowledgeable support team, preventing signal integrity issues. By acting as an extension of the engineering team, customer support ensures that the final PCB meets both performance and timeline expectations.

Key Ways Customer Support Enhances PCB Orders

1. Design Validation and Error Prevention

One of the most critical stages in PCB manufacturing is design validation. Errors in Gerber files, incorrect component footprints, or misaligned drill holes can lead to costly rework or scrapped boards. A robust customer support team reviews design files before production, catching issues that might otherwise go unnoticed. For example, a support engineer might identify a via placement that violates minimum annular ring requirements (e.g., 0.15 mm for a Class 2 PCB) and suggest adjustments to ensure manufacturability.

Support teams also use Design for Manufacturability (DFM) checks to verify that the PCB design aligns with the manufacturer's capabilities. This proactive approach reduces the risk of errors, such as over-etching or insufficient clearance, which can affect up to 20% of first-run prototypes if not addressed early. By providing detailed feedback, customer support empowers engineers to refine their designs for optimal performance.

2. Material and Process Guidance

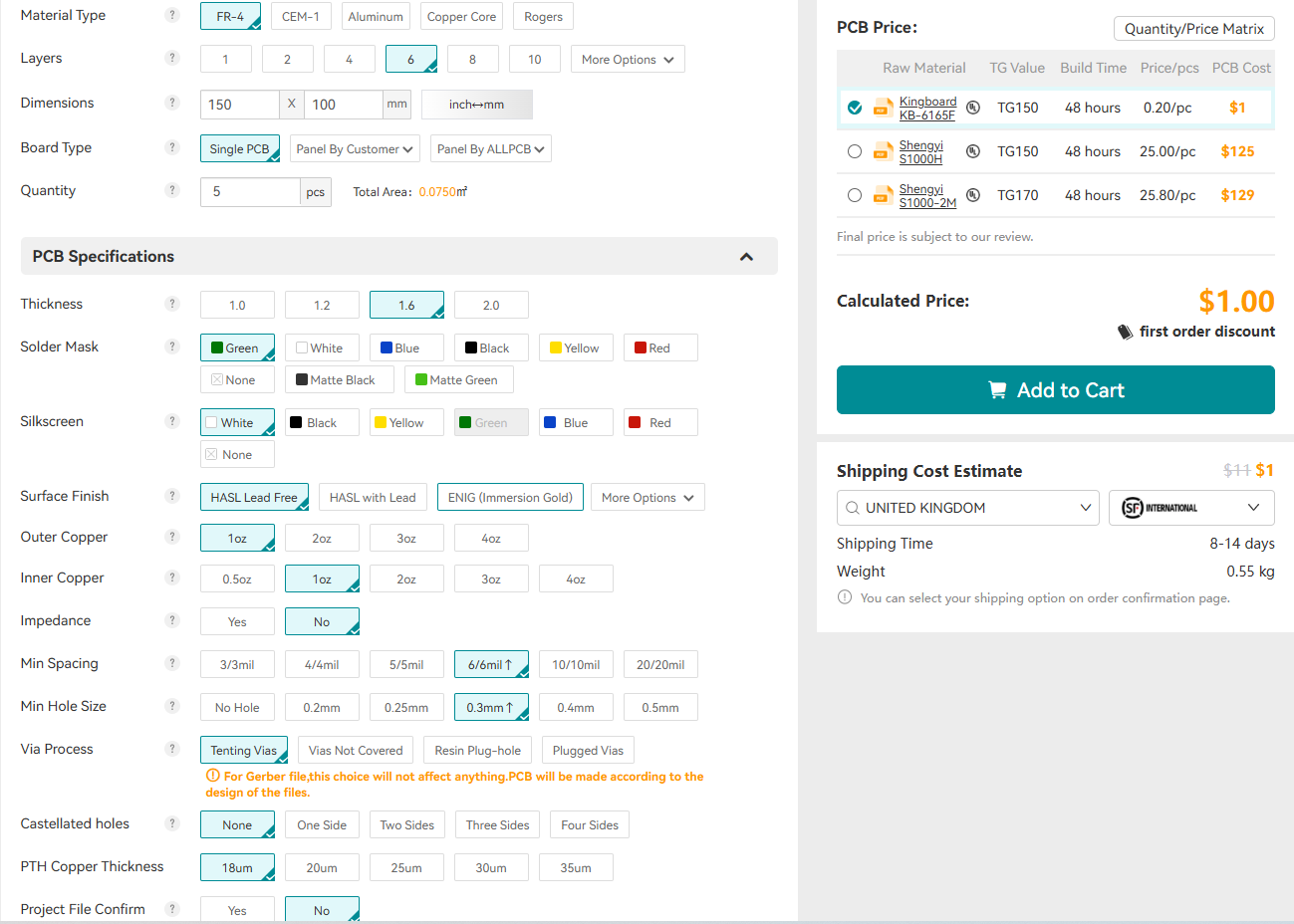

Choosing the right materials and manufacturing processes is crucial for meeting performance requirements, especially for high-frequency or high-power applications. For instance, selecting FR-4 for a standard PCB versus a high-Tg material (e.g., Tg 170°C) for a high-temperature application can significantly impact reliability. Customer support teams guide engineers through these decisions, offering insights into material properties, stack-up configurations, and cost trade-offs.

A knowledgeable support team can also recommend processes like controlled impedance routing for high-speed signals (e.g., ensuring 100-ohm differential pairs for USB 3.0) or surface finishes like ENIG for better solderability. By providing tailored recommendations, customer support ensures the PCB meets both functional and budgetary needs, reducing the likelihood of costly revisions.

3. Streamlined Communication for Quick Resolutions

Time is critical in PCB projects, especially for rapid prototyping or time-to-market-driven products. Delays due to miscommunication can push project timelines back by days or even weeks. Responsive customer support minimizes these risks by offering multiple communication channels—phone, email, live chat, or even dedicated account managers. For example, if an engineer encounters an issue with a component shortage during assembly, a quick response from the support team can suggest alternative parts or adjust the Bill of Materials (BOM) to keep the project on track.

Studies show that manufacturers with responsive customer support can reduce lead times by up to 15% compared to those with limited communication options. This efficiency is particularly valuable for engineers working on tight schedules or iterative designs.

4. Troubleshooting and Post-Production Support

Even with meticulous planning, issues can arise during or after production, such as soldering defects or unexpected performance issues. Customer support plays a vital role in troubleshooting these problems. For instance, if a PCB exhibits current leakage due to residual flux (a common issue that can cause corrosion), the support team can guide engineers through cleaning processes or recommend adjustments for future orders.

Post-production support also includes facilitating returns, reworks, or additional testing, such as Automated Optical Inspection (AOI) or Flying Probe Testing, to ensure the PCB meets specifications. This ongoing assistance builds trust and ensures long-term project success.

5. Navigating Global Logistics and Customs

For engineers working with international manufacturers, logistics and customs can be a significant hurdle. Tariffs, shipping delays, or documentation errors can disrupt timelines. Recent changes in U.S. tariff policies, for example, have increased scrutiny on electronics imports, with clearance thresholds still at $800 rather than the proposed $2,500. A customer support team well-versed in global logistics can guide engineers through these complexities, ensuring timely delivery and compliance with regulations.

Support teams can also provide real-time updates on order status, from fabrication to shipping, reducing uncertainty and allowing engineers to plan accordingly. This transparency is critical for projects with strict deadlines, such as those in the aerospace or medical sectors.

Best Practices for Engineers to Maximize Customer Support

To fully leverage customer support, engineers should adopt the following practices:

- Submit Clear and Complete Files: Provide accurate Gerber files, BOMs, and assembly drawings to minimize back-and-forth. For example, ensuring all layer files are correctly labeled (e.g., top copper, bottom solder mask) speeds up the review process.

- Ask Specific Questions: When seeking guidance, specify technical requirements, such as impedance values (e.g., 50 ohms for RF signals) or thermal constraints, to receive targeted advice.

- Engage Early and Often: Involve customer support during the design phase, not just after issues arise. Early collaboration can prevent costly mistakes, such as incorrect stack-up for a 10-layer HDI board.

- Utilize Multiple Communication Channels: Take advantage of phone, email, or live chat to resolve issues quickly, especially for urgent orders.

- Provide Feedback: Share project outcomes with the support team to help them refine their processes, fostering a stronger partnership for future orders.

By following these practices, engineers can ensure smoother collaboration and better outcomes, turning customer support into a strategic asset.

How ALLPCB Supports Your PCB Success

At ALLPCB, we understand that exceptional customer support is the cornerstone of successful PCB orders. Our team of experienced engineers and support specialists is dedicated to guiding you through every stage of the process, from design validation to global logistics. With our quick-turn prototyping services, we can deliver high-quality PCBs in as little as 24 hours, ensuring you meet tight deadlines. Our advanced manufacturing capabilities, including support for HDI designs and precise impedance control, combined with 24/7 customer support, make us a trusted partner for engineers worldwide. Whether you're troubleshooting a complex multilayer board or navigating international shipping, ALLPCB is here to ensure your project succeeds.

Conclusion

Customer support is more than just a service—it's a critical component of successful PCB orders. By providing design validation, material guidance, streamlined communication, troubleshooting, and logistics expertise, a responsive support team ensures that engineers can bring their designs to life without unnecessary delays or errors. For engineers, partnering with a manufacturer that prioritizes customer support means fewer headaches, faster turnarounds, and higher-quality PCBs.

By adopting best practices and engaging proactively with customer support, you can maximize the success of your PCB projects. Whether you're designing a high-speed digital board or a compact IoT device, the right support team is your ally in achieving excellence.

ALLPCB

ALLPCB