In today’s world, where technology evolves at a lightning pace, printed circuit boards (PCBs) are at the heart of nearly every electronic device. However, with innovation comes responsibility. Improper disposal of PCBs can harm the environment due to toxic materials like lead, mercury, and brominated flame retardants. So, how can engineers ensure eco-friendly PCB disposal while minimizing environmental impact? This guide dives into practical solutions, covering eco-friendly PCB disposal methods, PCB disposal best practices, the environmental impact of PCB disposal, green PCB design, and RoHS compliance in PCB disposal. Let’s explore actionable steps to make a positive difference.

Why Eco-Friendly PCB Disposal Matters

The environmental impact of PCB disposal is significant. When discarded improperly, PCBs release hazardous substances into soil and water, posing risks to ecosystems and human health. Studies suggest that electronic waste (e-waste), including PCBs, accounts for nearly 70% of toxic waste in landfills. With millions of tons of e-waste generated annually, engineers play a critical role in reducing this burden through sustainable practices.

Beyond environmental concerns, adopting eco-friendly PCB disposal methods aligns with global regulations like the Restriction of Hazardous Substances (RoHS) directive, which limits the use of harmful materials in electronics. Compliance not only ensures legal adherence but also enhances a company’s reputation as a responsible entity. Let’s break down the key aspects of sustainable PCB disposal and design to help engineers take meaningful action.

Understanding the Environmental Impact of PCB Disposal

PCBs are complex assemblies made of materials like copper, fiberglass, epoxy resin, and sometimes toxic substances such as lead and cadmium. When these boards end up in landfills or are incinerated, they can cause severe environmental damage. Here are some specific impacts:

- Soil and Water Contamination: Leaching of heavy metals like lead and mercury from PCBs can contaminate groundwater, affecting agriculture and drinking water supplies. Research indicates that even small amounts of lead can reduce soil fertility by up to 30% over time.

- Air Pollution: Incinerating PCBs releases toxic fumes, including dioxins and furans, which contribute to air pollution and respiratory issues. These pollutants can travel long distances, impacting regions far from the disposal site.

- Resource Waste: PCBs contain valuable materials like gold, silver, and copper. Improper disposal means losing these resources, increasing the demand for mining and further environmental degradation.

Recognizing these risks, engineers must prioritize PCB disposal best practices to mitigate harm and promote sustainability.

Eco-Friendly PCB Disposal Methods for Engineers

Implementing eco-friendly PCB disposal methods is not just about compliance—it’s about creating a safer planet. Below are practical approaches engineers can adopt:

1. Recycling PCBs for Material Recovery

Recycling is one of the most effective ways to handle PCB waste. The process involves separating valuable metals like copper (often 20-30% of a PCB’s weight) and gold from non-metallic components like epoxy and fiberglass. Advanced recycling techniques, such as hydrometallurgy and pyrometallurgy, can recover up to 95% of metals from PCBs, reducing the need for raw material extraction.

Engineers can partner with certified e-waste recycling facilities that follow strict environmental standards. These facilities disassemble PCBs, extract reusable components, and safely manage hazardous materials. Always verify that the recycler adheres to local and international regulations to avoid contributing to unethical practices.

2. Reusing Functional Components

Before disposal, consider whether parts of the PCB or entire boards can be reused. Many electronic components on discarded PCBs remain functional, even if the device itself is obsolete. Reusing these parts in prototypes or low-cost projects can extend their lifecycle and reduce waste. This practice not only saves resources but also cuts costs in design and testing phases.

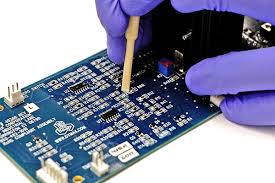

3. Safe Chemical Dissolution Techniques

Innovative methods, such as small-molecule-assisted dissolution, offer a greener way to break down PCB materials. Unlike traditional high-temperature processes that require over 200°C, these techniques operate at lower temperatures and dissolve thermosetting polymers in epoxy-based PCBs efficiently. This method minimizes energy use and toxic emissions, making it a promising option for sustainable disposal.

4. Proper Hazardous Waste Management

For PCBs containing hazardous substances, proper handling is crucial. Engineers should classify and store such waste in designated containers to prevent leakage. Partnering with licensed hazardous waste disposal services ensures that toxic materials are treated or disposed of safely, avoiding environmental contamination.

PCB Disposal Best Practices: A Step-by-Step Approach

To streamline eco-friendly disposal, follow these PCB disposal best practices tailored for engineers:

- Inventory and Segregation: Catalog all PCB waste and segregate it based on material composition (e.g., lead-free vs. lead-containing boards). This step simplifies recycling and ensures compliance with regulations like RoHS.

- Documentation: Maintain detailed records of disposal processes, including the quantity of waste, recycling partners, and disposal dates. This transparency helps in audits and demonstrates commitment to sustainability.

- Employee Training: Educate team members on proper handling and disposal techniques to prevent accidental environmental harm. Training should cover safety protocols for managing hazardous materials.

- Partner with Certified Recyclers: Work only with recyclers certified by environmental agencies. Certification ensures that the recycler follows strict guidelines for waste processing and disposal.

- Monitor Regulatory Updates: Stay informed about changes in e-waste laws and standards, such as updates to RoHS or local disposal mandates, to remain compliant.

By integrating these practices into daily operations, engineers can significantly reduce the environmental footprint of PCB disposal.

Green PCB Design: Preventing Waste at the Source

While disposal is critical, designing PCBs with sustainability in mind can prevent waste from the start. Green PCB design focuses on minimizing environmental impact throughout the product lifecycle. Here’s how engineers can incorporate green principles:

1. Use Eco-Friendly Materials

Opt for lead-free solder and halogen-free laminates to reduce toxicity. These materials align with RoHS compliance for PCB disposal and make recycling easier. Additionally, consider biodegradable substrates or bio-based resins for non-critical applications, as they break down more naturally than traditional materials.

2. Design for Disassembly

Create PCBs that are easy to disassemble at the end of their life. Use modular designs with easily removable components to facilitate reuse and recycling. Avoid excessive use of adhesives or permanent fixtures that complicate separation processes.

3. Minimize Material Use

Optimize PCB layouts to reduce material waste during manufacturing. For instance, tighter trace spacing (while maintaining signal integrity at, say, 50 ohms impedance for high-speed designs) can shrink board size without compromising performance. Smaller boards mean less raw material and easier disposal.

4. Extend Product Lifespan

Design durable PCBs that withstand environmental stresses, reducing the frequency of replacements. Incorporate protective coatings to prevent corrosion and ensure signal speeds remain consistent (e.g., maintaining 3.125 Gbps for high-speed data lines). Longer-lasting PCBs mean less frequent disposal.

RoHS Compliance in PCB Disposal: What Engineers Need to Know

The RoHS directive, enacted in the European Union, restricts the use of six hazardous substances in electrical and electronic equipment, including lead, mercury, and cadmium. RoHS compliance in PCB disposal is not just a legal requirement in many regions—it’s a cornerstone of eco-friendly practices. Here’s how to ensure adherence:

- Material Selection: Use RoHS-compliant materials during PCB manufacturing to simplify disposal. Non-compliant materials require specialized handling, increasing costs and environmental risks.

- Labeling: Clearly label PCBs as RoHS-compliant or non-compliant to guide disposal processes. This helps recyclers identify appropriate treatment methods.

- Supplier Verification: Work with suppliers who provide RoHS-certified components and materials. Request documentation to confirm compliance before integrating parts into designs.

- End-of-Life Planning: Include RoHS compliance in your end-of-life strategy for PCBs. Ensure that disposal partners are equipped to handle compliant and non-compliant waste separately.

Staying RoHS-compliant not only reduces environmental impact but also positions engineers as leaders in sustainable innovation.

Challenges in Eco-Friendly PCB Disposal and How to Overcome Them

Despite the benefits, eco-friendly PCB disposal comes with challenges. Here are common hurdles and solutions:

- Cost of Recycling: Recycling can be expensive, especially for small-scale operations. To offset costs, focus on bulk disposal with certified recyclers who offer competitive rates for larger volumes.

- Lack of Awareness: Many engineers may not fully understand disposal regulations or options. Address this by organizing workshops or leveraging online resources from environmental agencies.

- Complex Waste Streams: PCBs often contain mixed materials, complicating recycling. Invest in pre-sorting techniques to separate metals, plastics, and hazardous components before disposal.

By proactively addressing these challenges, engineers can make sustainable disposal a seamless part of their workflow.

The Future of Eco-Friendly PCB Disposal

The push for sustainability is driving innovation in PCB disposal and design. Emerging technologies, like bio-based PCB substrates and automated recycling systems, promise to further reduce environmental impact. Additionally, stricter global regulations are encouraging companies to adopt green practices, making eco-friendly disposal a standard rather than an exception.

Engineers have the power to shape this future by advocating for sustainable materials, supporting recycling initiatives, and designing with the environment in mind. Every small step—whether it’s choosing a lead-free solder or partnering with a certified recycler—contributes to a cleaner planet.

Conclusion: Taking Action for a Greener Tomorrow

As stewards of technology, engineers have a unique opportunity to minimize the environmental impact of PCB disposal. By adopting eco-friendly PCB disposal methods, following PCB disposal best practices, embracing green PCB design, and ensuring RoHS compliance, you can make a tangible difference. Start by evaluating your current disposal processes, partnering with certified recyclers, and designing with sustainability in mind. Together, these efforts build a foundation for a greener, more responsible electronics industry.

Let’s commit to sustainable practices today for a healthier planet tomorrow. Your role in eco-friendly PCB disposal is not just a responsibility—it’s a chance to lead by example in the engineering community.

ALLPCB

ALLPCB