In the rapidly evolving world of electronics, sustainability is becoming a top priority. Bio-based flexible PCBs (Printed Circuit Boards) are emerging as a groundbreaking solution to reduce environmental impact while maintaining high performance. If you're searching for eco-friendly flex PCB alternatives, biodegradable flex PCB substrates, or sustainable materials for flex circuit boards, this blog will guide you through the latest innovations and benefits of bio-based materials in flexible electronics.

At ALLPCB, we're committed to supporting the shift toward greener technologies. In this post, we'll explore what bio-based flexible PCBs are, why they matter, and how they're shaping the future of sustainable electronics. Let's dive into the details of this exciting frontier.

What Are Bio-Based Flexible PCBs?

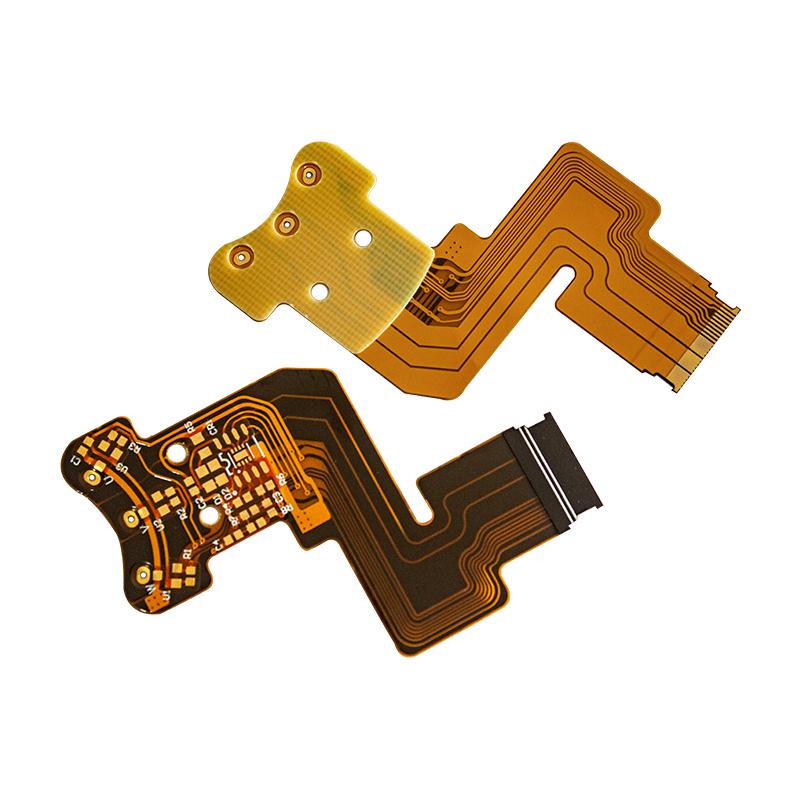

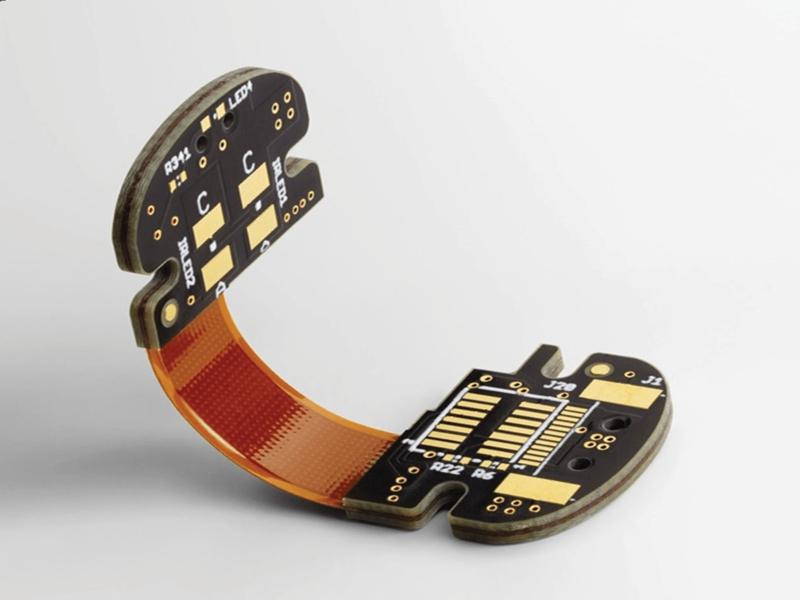

Bio-based flexible PCBs are circuit boards made from materials derived from natural, renewable resources instead of traditional petroleum-based plastics. These substrates are designed to be biodegradable or compostable, breaking down naturally over time without leaving harmful residues. Unlike conventional flexible PCBs, which often use materials like polyimide or polyester that contribute to electronic waste (e-waste), bio-based alternatives aim to minimize environmental harm.

These innovative materials can include bio-based polymers, cellulose composites, and other plant-derived substances. They are engineered to provide the flexibility and durability needed for modern electronics while aligning with eco-friendly principles. For engineers and designers, bio-based flexible PCBs offer a way to create sustainable products without compromising on performance.

Why Sustainable Electronics Matter

The electronics industry generates millions of tons of e-waste each year. According to a 2020 report by the United Nations, global e-waste reached 53.6 million metric tons, with only 17.4% being recycled properly. Traditional PCBs, especially flexible ones used in wearables, medical devices, and consumer electronics, contribute significantly to this problem due to their non-biodegradable components.

Bio-based flexible PCB materials address this issue by offering biodegradable flex PCB substrates that decompose naturally. By adopting sustainable materials for flex circuit boards, manufacturers can reduce landfill waste, lower carbon footprints, and meet growing consumer demand for environmentally responsible products. This shift is not just a trend—it's a necessity for the future of our planet.

Key Benefits of Bio-Based Flexible PCBs

Switching to bio-based materials for the flexible PCB brings several advantages. Below are some of the key benefits that make these substrates a game-changer in the industry.

1. Environmental Impact Reduction

Bio-based flexible PCB materials are often compostable or biodegradable, meaning they break down into harmless components after their useful life. For example, some substrates made from polylactic acid (PLA), a bio-based polymer derived from corn starch, can decompose in industrial composting facilities within months. This drastically reduces the long-term environmental burden compared to traditional materials that persist for centuries.

2. Compatibility with High-Performance Applications

One concern with eco-friendly flex PCB alternatives is whether they can match the performance of conventional materials. Recent advancements show that bio-based substrates can achieve comparable mechanical and electrical properties. For instance, certain bio-based composites offer tensile strength and thermal stability suitable for applications like wearable sensors, where flexibility and durability are critical. While exact impedance values and signal speeds vary by material, many bio-based options support high-frequency signals in the range of 1-5 GHz, making them viable for modern devices.

3. Regulatory and Market Advantages

Governments and organizations worldwide are pushing for stricter regulations on e-waste and sustainability. By adopting sustainable materials for flex circuit boards, companies can stay ahead of compliance requirements and appeal to eco-conscious consumers. This proactive approach can also enhance brand reputation and open new market opportunities.

Types of Bio-Based Materials for Flexible PCBs

Several bio-based materials are being explored and developed as biodegradable flex PCB substrates. Here's a look at some of the most promising options currently shaping the industry.

1. Polylactic Acid (PLA) Composites

PLA is a widely used bio-based polymer made from renewable resources like corn or sugarcane. When combined with natural fibers such as flax, PLA composites can serve as flexible PCB substrates with decent mechanical strength. Research has shown that these materials can withstand bending cycles in the range of 10,000 to 50,000 without significant degradation, making them suitable for low-to-medium stress applications.

2. Cellulose-Based Substrates

Cellulose, derived from wood pulp or cotton, is another promising material for compostable flexible PCBs. Its natural flexibility and biodegradability make it an excellent candidate for sustainable electronics. Some cellulose-based substrates have demonstrated dielectric constants around 2.5 to 3.5, which are comparable to traditional materials used in flexible circuits.

3. Bio-Epoxy Resins

Bio-epoxy resins, made from plant-based oils, offer a more durable option for eco-friendly flex PCB alternatives. These materials provide better thermal resistance, with glass transition temperatures (Tg) ranging from 80°C to 120°C, allowing them to handle moderate heat during operation or soldering processes.

While these materials are still evolving, they represent significant steps toward sustainable electronics. Ongoing research aims to improve their electrical properties, such as reducing signal loss at higher frequencies, to meet the demands of cutting-edge applications.

Challenges in Adopting Bio-Based Flexible PCBs

Despite their potential, bio-based flexible PCB materials face several challenges that need to be addressed for widespread adoption. Understanding these hurdles can help engineers and manufacturers make informed decisions.

1. Performance Limitations

While bio-based substrates have made great strides, they often fall short in high-performance scenarios. For example, their moisture absorption rates can be higher than traditional materials, potentially affecting electrical reliability. Signal integrity at frequencies above 10 GHz may also be a concern for some applications, though advancements are closing this gap.

2. Cost and Scalability

Producing bio-based materials at scale can be more expensive than conventional substrates due to limited supply chains and processing complexities. However, as demand grows and production methods improve, the PCB cost is expected to decrease, making these materials more accessible.

3. Durability and Lifespan

Biodegradable flex PCB substrates are designed to break down over time, which can raise concerns about long-term durability. For applications requiring extended lifespans, such as industrial equipment, manufacturers must balance biodegradability with operational reliability.

Recent Innovations in Sustainable Materials for Flex Circuit Boards

The field of sustainable electronics is advancing rapidly, with new developments making bio-based flexible PCBs more viable every day. Here are some noteworthy innovations based on recent industry trends and research.

One exciting development is the use of flame-retarded bio-based composites for PCB substrates. These materials combine environmental benefits with enhanced safety features, addressing concerns about flammability in electronics. Studies have shown that such composites can achieve UL-94 V-0 ratings, a standard for flame resistance, while remaining compostable.

Another breakthrough involves the integration of natural fibers like flax into bio-based polymers. This approach not only improves mechanical strength but also reduces the overall carbon footprint of production. Some of these materials have been tested in flexible circuits for consumer electronics, demonstrating bending radii as low as 5 mm without cracking.

Additionally, researchers are exploring bio-waste as a source for PCB substrates. For instance, agricultural byproducts are being transformed into viable materials for electronics, further reducing waste and promoting a circular economy.

How Bio-Based Flexible PCBs Are Shaping the Future

The adoption of bio-based flexible PCBs is paving the way for a more sustainable electronics industry. As technology progresses, we can expect these materials to play a larger role in various sectors, from healthcare to automotive. Here's how they're contributing to the future.

1. Enabling Green Wearables and IoT Devices

Wearable devices and Internet of Things (IoT) products often rely on flexible PCBs due to their compact, lightweight designs. Bio-based substrates are ideal for these applications, offering an eco-friendly solution for short-lifecycle products that are frequently replaced.

See more: Flexible PCB Design for Medical Wearables: Balancing Performance and Biocompatibility

2. Supporting Medical Innovations

In the medical field, disposable electronics like biosensors and diagnostic patches are gaining popularity. Compostable flexible PCBs made from bio-based materials ensure that these single-use devices don't contribute to long-term waste, aligning with healthcare sustainability goals.

3. Reducing Carbon Footprint in Manufacturing

Producing bio-based materials often requires less energy and emits fewer greenhouse gases compared to petroleum-based alternatives. This reduction in carbon footprint is a significant step toward achieving net-zero goals in electronics manufacturing.

Practical Steps for Implementing Bio-Based Flexible PCBs

For engineers and manufacturers looking to integrate bio-based flexible PCBs into their designs, here are some actionable steps to get started.

First, evaluate the specific requirements of your application, such as operating temperature, frequency range, and expected lifespan. Match these needs with the properties of available bio-based materials to ensure compatibility.

Next, collaborate with material suppliers to source high-quality biodegradable flex PCB substrates. Request detailed datasheets to understand electrical properties like dielectric constant (typically 2.5-4.0 for bio-based options) and loss tangent, which impacts signal integrity.

Finally, conduct thorough testing under real-world conditions. Simulate bending, thermal stress, and humidity exposure to confirm that the chosen material meets performance standards. Start with small-scale prototypes before moving to full production.

Conclusion: Embracing the Sustainable Revolution

Bio-based flexible PCBs represent a new frontier in sustainable electronics, offering a powerful way to reduce e-waste and promote environmental responsibility. With advancements in biodegradable flex PCB substrates, eco-friendly flex PCB alternatives, and sustainable materials for flex circuit boards, the industry is moving toward a greener future. While challenges like performance and cost remain, ongoing innovations are making these materials more practical for a wide range of applications.

At ALLPCB, we're excited to be part of this transformation. By exploring and adopting bio-based flexible PCB materials, we can help engineers and manufacturers create products that are both cutting-edge and kind to the planet. Together, let's build a sustainable tomorrow, one circuit at a time.

ALLPCB

ALLPCB