Choosing the right microcontroller (MCU) for your autonomous vehicle control PCB is a critical decision that impacts safety, performance, and reliability. With the rise of self-driving technology, the demand for high-performance, safety-rated MCUs has skyrocketed. In this guide, we'll walk you through the key factors to consider when selecting an MCU, including an automotive microcontroller comparison, the importance of real-time microcontroller for autonomous vehicles, and essential microcontroller PCB design guidelines. Whether you're designing for advanced driver-assistance systems (ADAS) or full autonomy, this blog will help you make an informed choice.

Why the Right Microcontroller Matters for Autonomous Vehicles

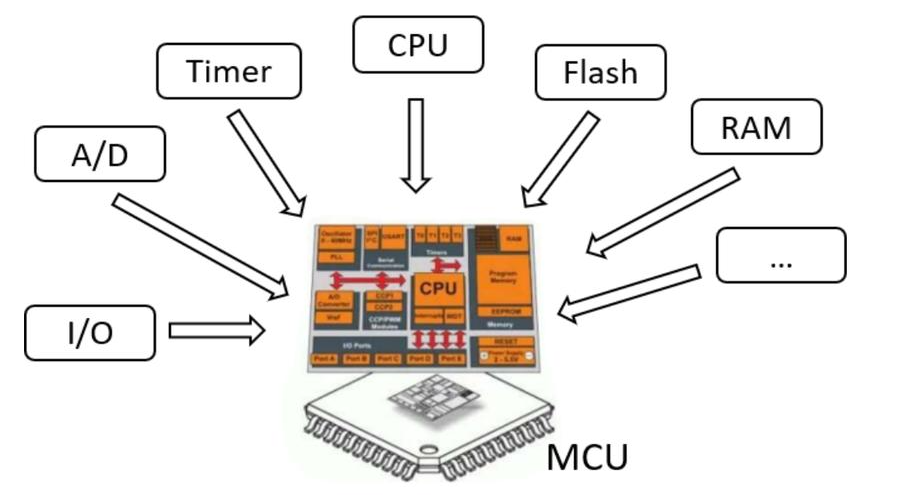

Autonomous vehicles rely on complex systems to process sensor data, make real-time decisions, and ensure passenger safety. At the heart of these systems lies the microcontroller, which acts as the brain of the control PCB. A poorly chosen MCU can lead to delays in processing, safety failures, or inefficient power usage. On the other hand, selecting a high-performance automotive MCU ensures seamless operation, compliance with safety standards, and scalability for future updates.

In this post, we'll break down the essential criteria for choosing an MCU, compare key features, and provide actionable tips for integrating it into your PCB design. Let's dive into the details to help you build a robust and reliable control system for autonomous vehicles.

Key Factors in Selecting a Microcontroller for Autonomous Vehicles

When choosing an MCU for your autonomous vehicle control PCB, several factors come into play. Below, we explore the most critical aspects to ensure your design meets the demands of modern automotive applications.

1. Real-Time Processing Capabilities

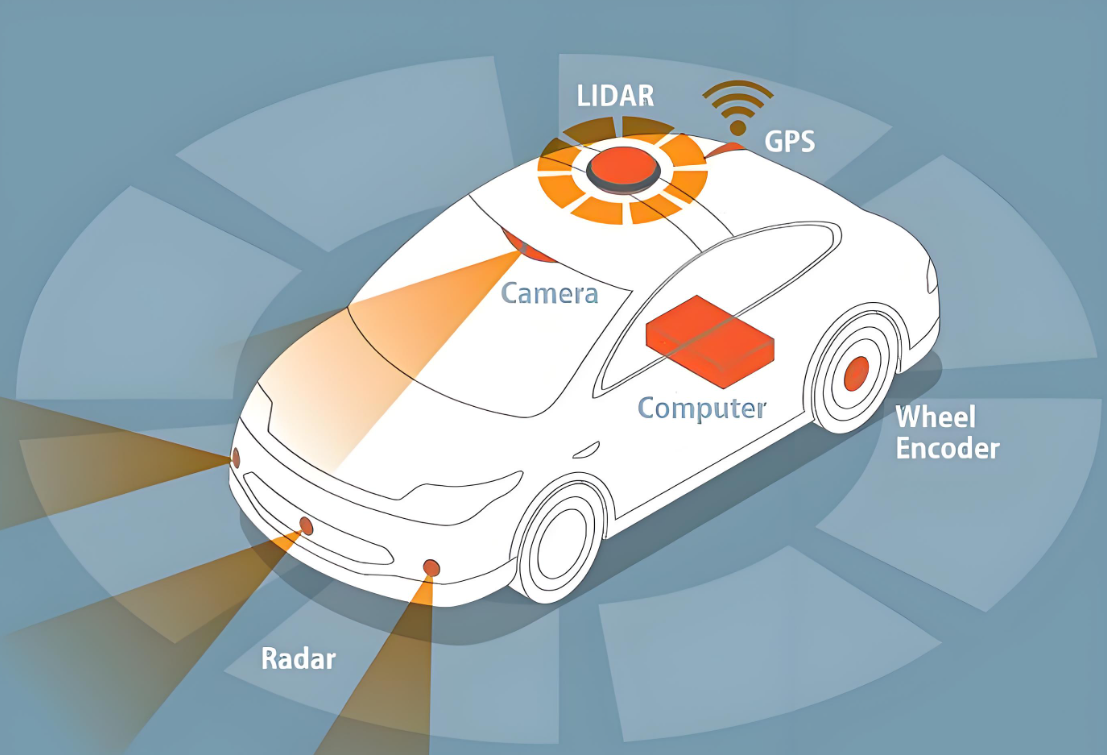

Autonomous vehicles must process massive amounts of data from cameras, LiDAR, radar, and other sensors in real time. A real-time microcontroller for autonomous vehicles is non-negotiable. Look for MCUs with high clock speeds (often exceeding 300 MHz) and low-latency interrupt handling to ensure split-second decision-making. For instance, processing delays as small as 10 milliseconds can affect collision avoidance systems, making speed a top priority.

Additionally, consider MCUs with dedicated hardware accelerators for tasks like image processing or machine learning. These features offload computational burdens from the core processor, improving overall efficiency.

2. Safety Ratings and Compliance

Safety is paramount in automotive applications, especially for autonomous systems. Opt for safety-rated microcontrollers that comply with standards like ISO 26262, which defines Automotive Safety Integrity Levels (ASIL). ASIL-D, the highest level, is often required for critical systems like braking and steering in self-driving cars. These MCUs include built-in features like error-correcting code (ECC) memory, redundant processing cores, and self-diagnostic capabilities to detect and mitigate faults.

Using a safety-rated MCU not only ensures compliance but also reduces the risk of system failures that could endanger lives. Always check the MCU's documentation for ASIL certification and supported safety mechanisms.

3. Performance and Scalability

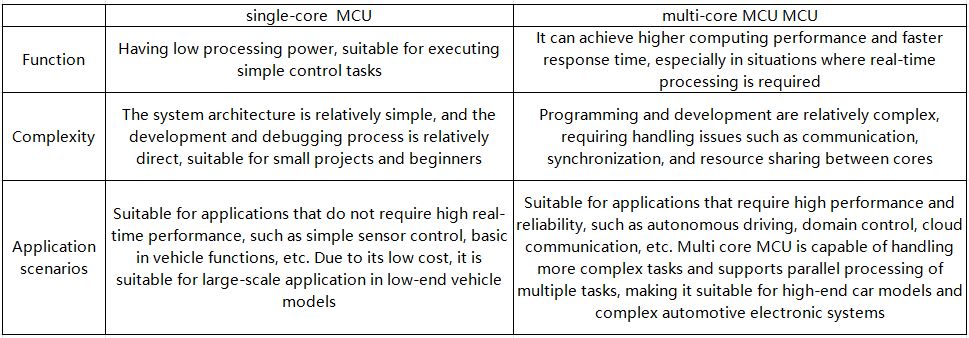

A high-performance automotive MCU is essential for handling the computational demands of autonomous driving. Look for multi-core architectures that can run multiple tasks simultaneously, such as sensor fusion and path planning. MCUs with 32-bit or 64-bit architectures often provide the necessary processing power, with some offering over 1000 DMIPS (Dhrystone Million Instructions Per Second) for complex algorithms.

Scalability is another factor. As autonomous technology evolves, your PCB design should accommodate future upgrades. Choose an MCU family with a range of performance options so you can scale up without redesigning the entire board.

4. Power Efficiency

Autonomous vehicles, especially electric ones, demand energy-efficient components to maximize battery life. Select an MCU with low-power modes that can shut down unused peripherals during idle periods. For example, some modern MCUs consume less than 1 μA in deep sleep mode while maintaining critical functions like wake-on-event capabilities.

Balancing power efficiency with performance ensures your control system doesn't drain the vehicle's energy reserves, which is crucial for long-range autonomous driving.

5. Connectivity and Integration

Modern autonomous vehicles require seamless communication between subsystems. Your MCU should support automotive-grade communication protocols like CAN (Controller Area Network), LIN (Local Interconnect Network), and Ethernet. Some advanced MCUs also offer support for time-sensitive networking (TSN) to ensure deterministic data transfer, which is vital for real-time control.

Integration with other components, such as GPUs for vision processing or external memory for data logging, is also important. Check the MCU's peripheral set to ensure it meets your system's connectivity needs.

Automotive Microcontroller Comparison: Key Features to Evaluate

To help you narrow down your options, let's dive into an automotive microcontroller comparison based on critical features. While specific product names are avoided, the following categories highlight what to look for in high-performance automotive MCUs.

- Processing Power: High-end MCUs often feature clock speeds above 400 MHz and multi-core designs for parallel processing. Mid-range options may offer 100-200 MHz, suitable for less demanding ADAS functions.

- Safety Features: Top-tier MCUs include ASIL-D certification, hardware-based fault detection, and lockstep cores for redundancy. Lower-tier options may only achieve ASIL-B, limiting their use in critical systems.

- Memory Capacity: Autonomous systems require substantial memory for data storage and processing. Look for MCUs with at least 4 MB of flash memory and 1 MB of RAM, with options for external memory expansion.

- Power Consumption: Premium MCUs offer advanced low-power modes, consuming under 100 μA in standby, while still supporting real-time wake-up features.

- Communication Interfaces: High-performance MCUs support multiple CAN-FD channels, Ethernet with TSN, and FlexRay for robust vehicle networking.

By comparing these features, you can align your MCU choice with the specific needs of your autonomous vehicle control PCB, whether it's for sensor processing, actuator control, or central computing.

Microcontroller PCB Design Guidelines for Autonomous Vehicles

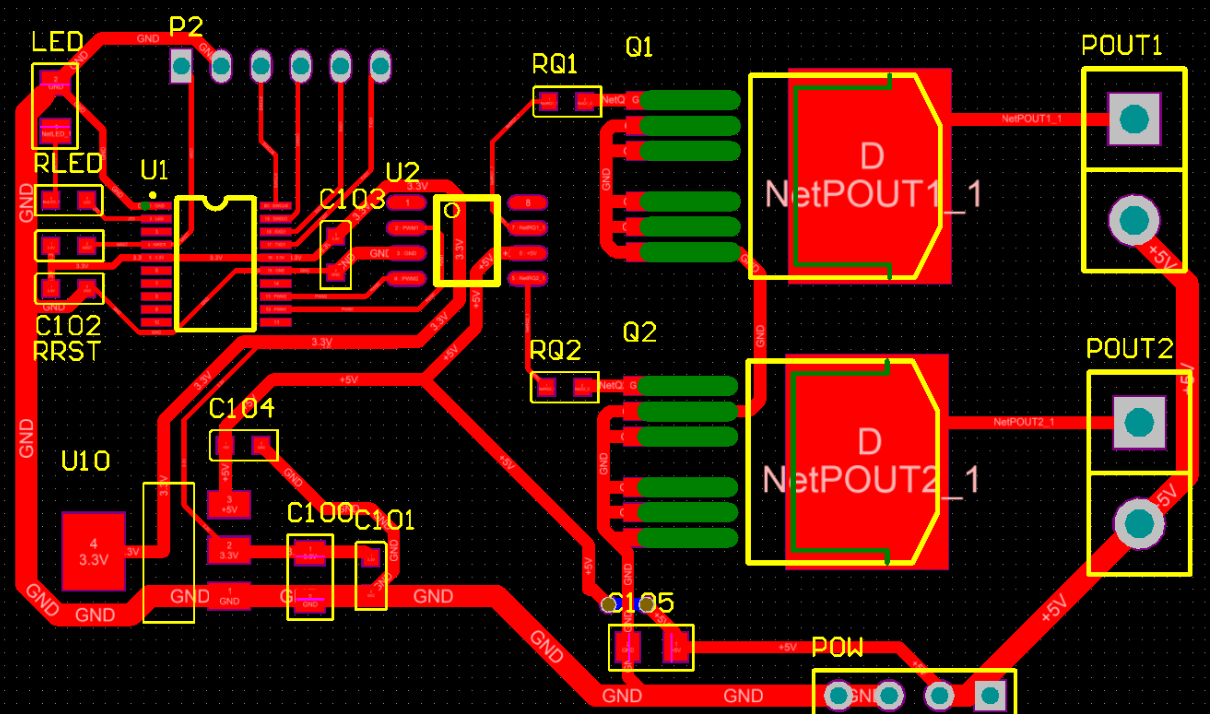

Once you've selected the right MCU, integrating it into your PCB design is the next challenge. Poor PCB layout can lead to signal integrity issues, electromagnetic interference (EMI), or thermal problems, all of which can compromise the performance of your autonomous vehicle control system. Follow these microcontroller PCB design guidelines to ensure reliability and efficiency.

1. Power Supply Design

Autonomous vehicle MCUs often require multiple voltage rails, such as 3.3V for digital logic and 1.2V for core processing. Use low-dropout (LDO) regulators or switching regulators with high efficiency to provide stable power. Place decoupling capacitors (typically 0.1 μF to 1 μF) close to the MCU's power pins to minimize voltage fluctuations. Ensure the power traces are wide enough to handle current demands, often at least 20 mils for high-current paths.

2. Ground Plane Layout

A solid ground plane is critical for reducing noise and ensuring signal integrity. Use a continuous ground plane on one layer of your PCB, avoiding splits that can create ground loops. Connect the MCU's ground pins directly to this plane with short vias to minimize impedance, ideally keeping via inductance below 1 nH.

3. Signal Integrity and Routing

High-speed signals, such as those from communication interfaces like Ethernet or CAN, require careful routing to prevent crosstalk and signal degradation. Keep trace lengths as short as possible, and maintain a consistent impedance (often 50 ohms for high-speed lines). Use differential pair routing for protocols like CAN-FD, ensuring the traces are matched in length to within 5 mils.

4. Thermal Management

High-performance MCUs generate significant heat, especially in autonomous systems running complex algorithms. Place thermal vias under the MCU to dissipate heat to a copper layer or heat sink. Ensure the PCB's thermal resistance is below 10°C/W for high-power applications. If necessary, incorporate temperature sensors near the MCU to monitor operating conditions and prevent overheating (ideal operating range is typically -40°C to 105°C for automotive-grade components).

5. EMI Mitigation

Electromagnetic interference can disrupt the sensitive operations of an autonomous vehicle control system. Use ferrite beads or EMI filters on power lines to suppress high-frequency noise. Shield critical traces with ground planes above and below, and avoid routing high-speed signals near the board edges where they can radiate interference. Compliance with automotive EMI standards, such as CISPR 25, is essential for reliable operation.

Challenges in MCU Selection and PCB Design for Autonomous Vehicles

Designing for autonomous vehicles comes with unique challenges that go beyond standard automotive applications. The sheer volume of data processed (often exceeding 4 GB per second from sensors) demands MCUs with exceptional performance, while strict safety requirements add layers of complexity to both hardware and PCB software design. Additionally, the harsh automotive environment—temperature swings from -40°C to 85°C, vibrations, and humidity—requires rugged components and robust PCB layouts.

To overcome these challenges, prioritize MCUs with proven reliability in automotive settings and follow best practices in PCB design. Testing your design under real-world conditions, such as thermal cycling and vibration stress, can reveal potential weaknesses before deployment.

How to Future-Proof Your Autonomous Vehicle Control PCB

The field of autonomous driving is evolving rapidly, with new algorithms, sensors, and communication standards emerging every year. To future-proof your design, select an MCU with ample processing headroom and support for over-the-air (OTA) updates. This allows you to upgrade firmware as new features or safety protocols are developed. Additionally, design your PCB with modular interfaces, such as expansion headers for additional sensors or communication modules, to accommodate future hardware upgrades.

Consider working with a trusted PCB manufacturing partner that offers advanced fabrication and assembly services tailored to automotive standards. This ensures your design is built with precision and reliability in mind, supporting the long-term success of your autonomous vehicle project.

Conclusion: Building a Reliable Foundation for Autonomous Driving

Selecting the best microcontroller for your autonomous vehicle control PCB is a foundational step in creating a safe, efficient, and high-performing system. By focusing on real-time processing, safety ratings, performance, and connectivity, you can choose a high-performance automotive MCU that meets the demands of self-driving technology. Pair this with careful adherence to microcontroller PCB design guidelines, and you'll build a control system that stands up to the rigors of the road.

Whether you're conducting an automotive microcontroller comparison or optimizing your PCB layout, the insights shared in this guide provide a roadmap for success. Take the time to evaluate your options, test your designs, and stay ahead of industry trends to ensure your autonomous vehicle project thrives in this fast-paced field.

ALLPCB

ALLPCB