In the world of modern lighting, LED technology stands out for its efficiency and versatility. When it comes to designing LED lighting systems, double-sided PCBs (Printed Circuit Boards) offer unique advantages that make them a top choice for engineers and manufacturers. If you're searching for solutions in double-sided PCB LED lighting, this blog will guide you through their benefits, especially in areas like thermal management, high-power LEDs, and overall PCB design. Let's dive into why double-sided PCBs are a game-changer for LED applications and how they can elevate your lighting projects.

What Are Double-Sided PCBs and Why Do They Matter for LED Lighting?

Double-sided PCBs are circuit boards with conductive copper layers on both the top and bottom sides. Unlike single-sided PCBs, which have components on only one side, double-sided boards allow for more complex circuits and higher component density by utilizing both surfaces. This design flexibility is crucial for LED lighting applications where space, performance, and heat dissipation are key concerns.

In LED PCB design, the ability to place components on both sides means more efficient use of space, which is especially important for compact lighting solutions like LED strips or small fixtures. Additionally, double-sided PCBs can handle more intricate wiring and power distribution, making them ideal for high-power LEDs that require robust electrical pathways.

Key Benefits of Double-Sided PCBs in LED Lighting Applications

Double-sided PCBs bring several advantages to the table when used in LED lighting systems. Below, we'll explore how they enhance design flexibility, improve thermal management, and support high-power LED performance.

1. Enhanced Design Flexibility for Compact LED Systems

One of the standout benefits of double-sided PCBs in LED lighting is the increased design flexibility they offer. With conductive layers on both sides, engineers can fit more components into a smaller footprint. This is particularly useful for LED applications where space is limited, such as in automotive lighting, portable devices, or architectural lighting fixtures.

For instance, in an LED strip light, using a double-sided PCB allows for tighter spacing of LEDs and supporting components like resistors and capacitors. This can result in a thinner, more streamlined product without sacrificing performance. The ability to route traces on both sides also reduces the risk of signal interference, ensuring stable operation even in complex designs.

2. Superior Thermal Management for High-Power LEDs

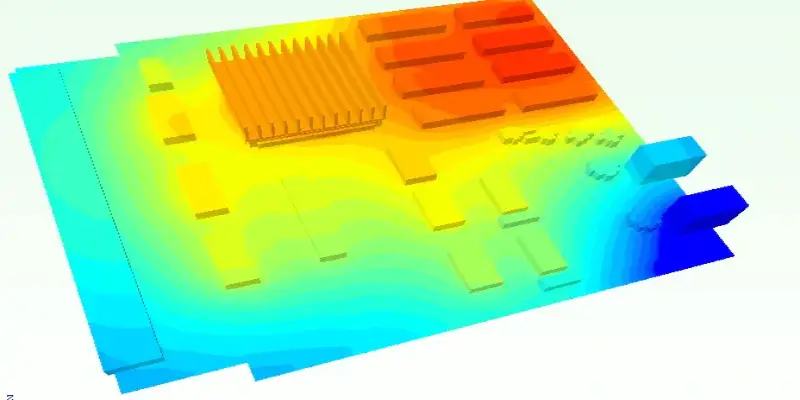

Thermal management is a critical aspect of LED PCB design, especially when dealing with high-power LEDs that generate significant heat. If not managed properly, excessive heat can reduce the lifespan of LEDs and degrade their performance. Double-sided PCBs help address this challenge by providing more surface area for heat dissipation.

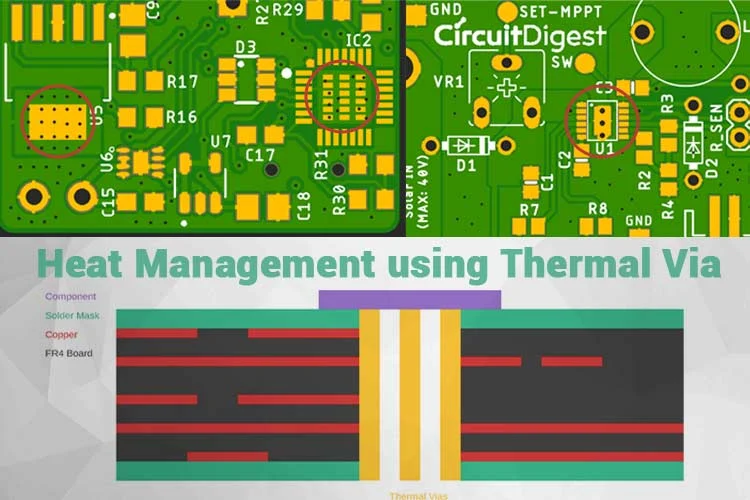

By placing heat-generating components like LEDs on one side and using the opposite side for thermal vias or heat sinks, double-sided PCBs create efficient pathways for heat to escape. Studies in thermal management have shown that improved heat dissipation can lower the junction temperature of LEDs by up to 10°C, extending their operational life by thousands of hours. This makes double-sided PCBs an excellent choice for high-power LED applications, such as industrial lighting or outdoor floodlights, where heat buildup is a constant concern.

3. Support for High-Power LED Configurations

High-power LEDs are increasingly popular in applications requiring intense brightness, such as street lighting, stadium lights, and grow lights for agriculture. These LEDs demand higher current and voltage, which in turn require robust circuit designs. Double-sided PCBs are well-suited for this task because they can accommodate thicker copper layers and wider traces to handle increased power loads.

For example, a high-power LED setup might require a current of 1A or more per LED. A double-sided PCB can distribute this current across multiple layers, reducing resistance and minimizing voltage drops. This ensures that each LED receives consistent power, resulting in uniform brightness and color output across the entire lighting system.

4. Cost-Effective for Medium to High-Volume Production

While double-sided PCBs may have a slightly higher initial cost compared to single-sided boards due to their complexity, they often prove more cost-effective in the long run, especially for medium to high-volume production. The ability to pack more functionality into a smaller board reduces the overall material costs and simplifies assembly. For LED lighting manufacturers, this translates to lower production expenses and faster time-to-market.

How Double-Sided PCBs Improve LED Lighting Performance

Beyond the core benefits, double-sided PCBs contribute to better performance in LED lighting systems through improved electrical efficiency and reliability. Let’s break down how these boards make a difference in real-world applications.

1. Reduced Signal Loss and Improved Electrical Efficiency

In LED lighting, maintaining consistent power delivery to each LED is essential for uniform illumination. Double-sided PCBs minimize signal loss by allowing shorter trace lengths and more direct routing paths. This is especially important in large LED arrays where long traces on a single-sided board could lead to voltage drops or uneven brightness.

For instance, in a panel of 100 LEDs arranged in a grid, a double-sided PCB can route power and ground connections on separate layers, reducing impedance to as low as 0.1 ohms per trace in some designs. This low impedance ensures that each LED operates at its optimal voltage, typically around 3.2V for standard white LEDs, leading to consistent light output and energy efficiency.

2. Increased Reliability for Long-Term Use

LED lighting systems are often expected to operate for tens of thousands of hours, sometimes in harsh environments like outdoor or industrial settings. Double-sided PCBs enhance reliability by providing stronger mechanical support for components and reducing the risk of trace damage. The dual-layer structure distributes stress more evenly across the board, preventing cracks or failures during thermal cycling.

Additionally, the extra space for redundant traces or backup circuits on a double-sided PCB can improve fault tolerance. If one trace fails due to corrosion or wear, an alternate path on the opposite side can maintain circuit functionality, ensuring uninterrupted lighting performance.

Design Tips for Double-Sided PCBs in LED Lighting

Creating an effective double-sided PCB for LED lighting requires careful planning and attention to detail. Below are some practical tips to optimize your PCB design for performance and longevity.

1. Prioritize Thermal Vias and Heat Sink Integration

When designing for high-power LEDs, include thermal vias—small holes filled with conductive material—that transfer heat from the LED side to the opposite side of the PCB. Pair these vias with a heat sink or metal core layer on the bottom side to maximize heat dissipation. A common practice is to use 0.3mm to 0.5mm diameter vias spaced at 1mm intervals near each LED for optimal thermal performance.

2. Optimize Trace Widths for Current Capacity

Ensure that trace widths are sufficient to handle the current required by your LEDs. For high-power LEDs drawing 1A, a trace width of at least 1.5mm with a copper thickness of 2oz (70 micrometers) is recommended to prevent overheating and voltage drops. Use both sides of the PCB to split high-current paths, balancing the load and reducing resistance.

3. Use Ground Planes for Stability

Incorporate a dedicated ground plane on one side of the double-sided PCB to stabilize the circuit and reduce electromagnetic interference (EMI). A solid ground plane can also act as an additional heat dissipation layer, further aiding thermal management in LED designs.

4. Test and Simulate Before Production

Before finalizing your double-sided PCB design, use simulation tools to test thermal performance and electrical behavior. Software can predict hot spots or voltage inconsistencies, allowing you to adjust the layout for better efficiency. For example, aim for a maximum junction temperature of 85°C for most LEDs to ensure a lifespan of over 50,000 hours.

Applications of Double-Sided PCBs in LED Lighting

Double-sided PCBs are used across a wide range of LED lighting applications due to their versatility and performance benefits. Here are a few examples of where they shine:

- Automotive Lighting: Headlights and taillights benefit from compact, high-power designs enabled by double-sided PCBs, ensuring bright illumination in tight spaces.

- Commercial Lighting: Office and retail lighting fixtures use these PCBs for efficient heat management and uniform light distribution.

- Outdoor Lighting: Streetlights and floodlights rely on double-sided PCBs to handle high-power LEDs and withstand environmental stress.

- Specialty Lighting: Grow lights for indoor farming or medical lighting systems leverage the design flexibility of double-sided PCBs for precise control over light output.

Challenges to Consider in Double-Sided PCB LED Design

While double-sided PCBs offer many advantages, there are challenges to keep in mind during the design and manufacturing process. Fabrication can be more complex than with single-sided boards, requiring precise alignment of layers and vias. This can increase production time and cost for small runs. Additionally, soldering components on both sides demands careful handling to avoid damaging delicate LED components or creating cold joints.

To mitigate these issues, work with experienced PCB manufacturing partners who can ensure high-quality assembly and testing. Investing in automated soldering and inspection processes can also reduce errors and improve the reliability of the final product.

Conclusion: Why Choose Double-Sided PCBs for LED Lighting?

Double-sided PCBs are a powerful solution for LED lighting applications, offering unmatched design flexibility, superior thermal management, and robust support for high-power LEDs. Whether you're working on compact consumer lighting or large-scale industrial systems, these boards provide the performance and reliability needed to succeed. By optimizing your LED PCB design with double-sided layouts, you can achieve better efficiency, longer lifespan, and cost savings in production.

At ALLPCB, we understand the unique demands of LED lighting projects and are committed to supporting engineers with high-quality PCB solutions. If you're ready to take your LED designs to the next level, consider the benefits of double-sided PCBs and explore how they can transform your next project.

ALLPCB

ALLPCB