When it comes to designing and programming drone flight control PCBs, choosing the right firmware and software is critical for performance, stability, and customization. As a developer, you need to understand how options like Betaflight, ArduPilot, and iNav impact your drone's functionality and how they integrate with your PCB design. This guide dives deep into firmware and software considerations for drone flight controller PCBs, offering actionable insights into drone PCB programming and flight controller software selection.

In this blog, we'll explore the key firmware options available, their unique features, and how they align with specific drone applications. We'll also cover the essentials of integrating firmware with PCB hardware, tips for optimizing performance, and best practices for developers working on drone projects. Whether you're building a racing drone or a long-range mapping quadcopter, this post will help you make informed decisions.

Why Firmware and Software Matter for Drone Flight Control PCBs

Firmware and software act as the brain of your drone, translating inputs from sensors and user commands into precise motor control and flight behavior. For developers working on drone PCB programming, the choice of flight controller software directly affects how well the hardware performs under various conditions. A mismatched firmware can lead to instability, poor response times, or even crashes, while the right one can unlock advanced features like GPS navigation or acrobatic maneuvers.

The firmware you select must be compatible with your flight controller hardware, support the sensors and peripherals on your PCB, and cater to the specific needs of your drone's application. Let’s break down the most popular drone flight controller firmware options and see how they fit into the development process.

Popular Drone Flight Controller Firmware Options

1. Betaflight: The Go-To for FPV and Racing Drones

Betaflight is one of the most widely used flight controller software options, especially for FPV (First-Person View) racing and freestyle drones. Known for its high performance and precision, Betaflight offers developers a robust platform to fine-tune flight characteristics. It supports a wide range of flight controller hardware, making it a versatile choice for drone PCB programming.

Key features of Betaflight include:

- Advanced PID Tuning: Allows developers to adjust Proportional, Integral, and Derivative values for optimal flight stability and responsiveness. Typical PID values for racing drones might range from P: 4-6, I: 2-3, and D: 20-30, depending on motor and frame setup.

- Low Latency: Betaflight minimizes input lag, crucial for competitive racing where response times can be as low as 2-5 milliseconds.

- Community Support: With a large user base, finding troubleshooting guides and custom configurations is straightforward.

For developers, Betaflight is ideal if your drone flight controller PCB is designed for high-speed applications. However, it lacks advanced navigation features like autonomous flight paths, so it may not suit drones built for mapping or long-range missions.

2. ArduPilot: Powering Autonomous and Large-Scale Drones

ArduPilot stands out as a powerful open-source flight controller software for drones requiring autonomous capabilities. It’s often used in larger drones for applications like aerial surveying, agriculture, and military operations. As a developer, ArduPilot gives you extensive control over flight parameters and hardware integration on your drone PCB.

Key features of ArduPilot include:

- Autonomous Flight Modes: Supports waypoint navigation, return-to-home, and geofencing, making it ideal for drones with GPS modules integrated into the PCB.

- Wide Hardware Compatibility: Works with various microcontrollers and sensors, allowing flexibility in PCB design.

- Custom Scripting: Developers can write custom scripts in Lua to extend functionality, such as automated payload drops or sensor data logging.

ArduPilot is more complex to set up compared to Betaflight, often requiring a deeper understanding of firmware configuration. It’s best suited for developers working on drone flight controller firmware for professional or industrial applications where autonomy is key.

3. iNav: A Middle Ground for Navigation and Simplicity

iNav is another popular choice among developers, offering a balance between Betaflight’s performance and ArduPilot’s navigation features. It’s a great option for drones that need basic GPS capabilities without the complexity of ArduPilot. iNav is often used for fixed-wing drones and smaller quadcopters with navigation requirements.

Key features of iNav include:

- GPS Navigation: Supports return-to-home and position hold modes, useful for drones with integrated GPS receivers on the PCB.

- User-Friendly Interface: Easier to configure than ArduPilot, with intuitive settings for altitude and position control.

- Compatibility: Works well with many flight controller boards, though not as extensively as Betaflight.

For developers focusing on drone PCB programming for hobbyist or semi-professional drones, iNav offers a practical solution that doesn’t require extensive coding knowledge.

Integrating Firmware with Drone Flight Control PCBs

Once you’ve chosen your flight controller software, the next step is integrating it with your drone PCB. This process involves several considerations to ensure compatibility and performance. Let’s walk through the key aspects of drone PCB programming with firmware.

1. Hardware Compatibility

Before flashing firmware onto your flight controller, verify that your PCB hardware supports the chosen software. For example:

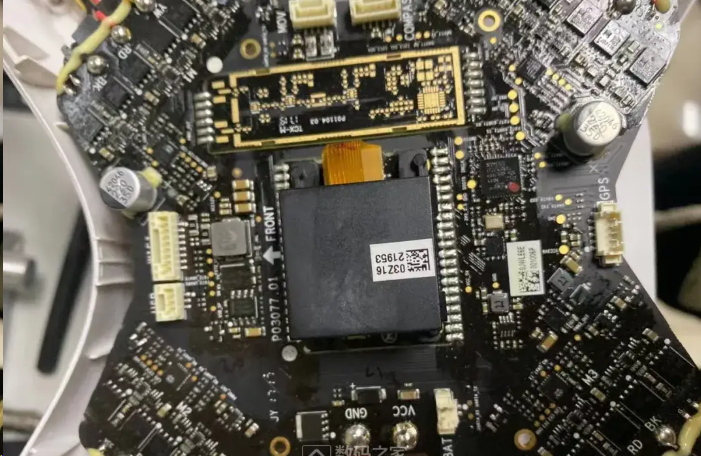

- Microcontroller: Most modern flight controllers use STM32 chips (like F4 or F7 series) with clock speeds ranging from 72 MHz to 216 MHz. Betaflight and iNav often require at least an F4 processor for optimal performance, while ArduPilot may work with older chips but benefits from faster processing.

- Sensors: Ensure your PCB includes compatible gyroscopes, accelerometers (often combined in an IMU like the MPU6000), and barometers if altitude hold is needed. Sensor data rates should match firmware requirements—typically 8 kHz for gyro data in Betaflight.

- Connectors: UART ports for GPS, SBUS for receiver input, and ESC signal outputs must align with firmware pin mapping.

Mismatches can lead to firmware crashes or unresponsive drones, so double-check datasheets and firmware documentation during the PCB design phase.

2. Flashing and Configuration

Flashing firmware involves uploading the software to your flight controller using a USB connection and a configurator tool specific to the firmware (e.g., Betaflight Configurator, Mission Planner for ArduPilot, or iNav Configurator). Follow these steps:

- Download the latest stable firmware version from the official repository.

- Connect your flight controller to your computer via USB.

- Use the configurator to select your board and flash the firmware.

- Configure settings like motor protocols (e.g., DShot600 with a 600 Hz update rate for ESCs) and sensor calibration.

Developers should also back up default settings before making changes, as incorrect configurations can cause erratic flight behavior.

3. Signal Integrity on the PCB

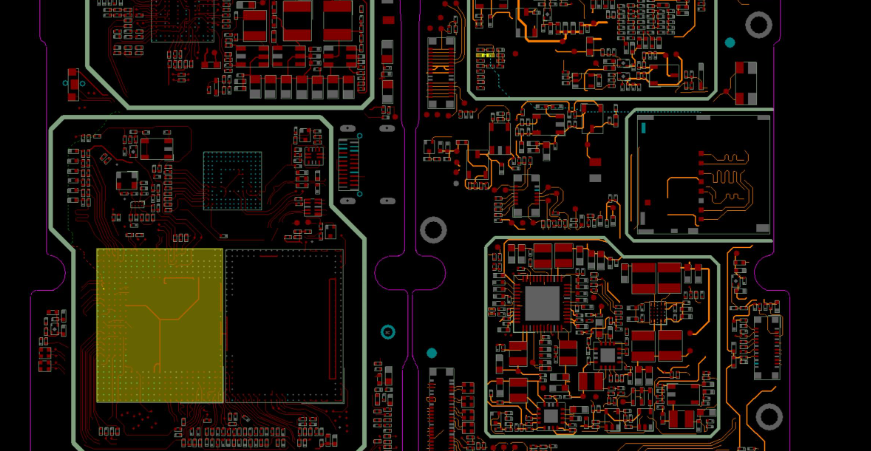

Signal integrity is crucial when designing a drone flight control PCB. Firmware relies on clean, fast signals from sensors and to actuators. Poor PCB design can introduce noise or delays, affecting flight stability. Consider these factors:

- Trace Impedance: Maintain controlled impedance for high-speed signals like SPI or I2C used by sensors. A typical target is 50 ohms for single-ended traces to minimize signal reflection.

- Ground Planes: Use solid ground planes to reduce electromagnetic interference (EMI), which can disrupt gyro readings.

- Decoupling Capacitors: Place capacitors (e.g., 0.1 μF ceramic) near power pins of the microcontroller and sensors to stabilize voltage and filter noise.

Testing signal integrity with an oscilloscope during development can help identify issues before they impact firmware performance.

Optimizing Performance with Flight Controller Software

Beyond integration, developers can optimize drone performance by tweaking firmware settings and leveraging software features. Here are some strategies tailored to drone flight controller firmware:

1. Fine-Tuning PID Values

PID (Proportional-Integral-Derivative) tuning is essential for flight stability. Each firmware handles PID loops slightly differently, but the goal is to balance responsiveness and smoothness. For instance, in Betaflight, start with default values and adjust based on flight tests:

- Increase P for faster response (e.g., from 4.0 to 5.0) if the drone feels sluggish.

- Adjust I to correct drift (e.g., 2.5 to 3.0) during sustained hover.

- Raise D to dampen oscillations (e.g., 20 to 25) if the drone overshoots during quick maneuvers.

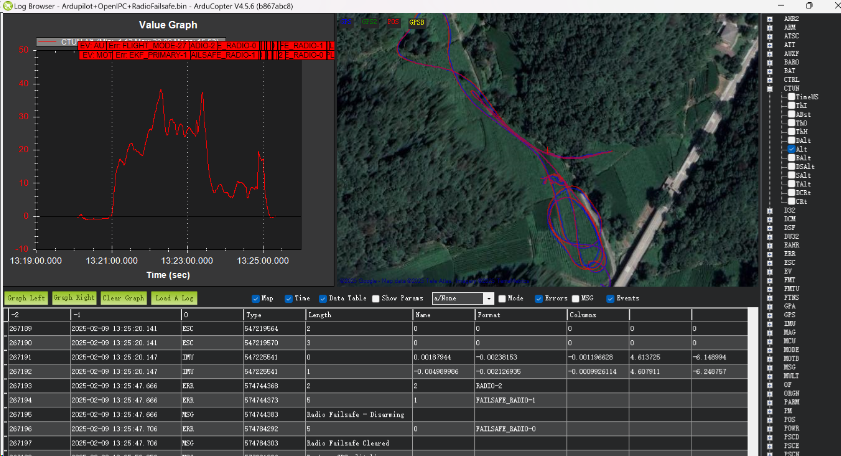

Use blackbox logging (available in Betaflight and iNav) to analyze flight data and refine these values.

2. Leveraging Advanced Features

Each firmware offers unique tools to enhance performance. For example:

- Betaflight: Enable dynamic filtering to reduce motor noise impacting gyro data, improving flight smoothness.

- ArduPilot: Set up automated missions with waypoints for consistent data collection in surveying drones.

- iNav: Use altitude hold mode for stable hovering, ideal for photography drones.

Explore firmware documentation to uncover features that match your drone’s purpose.

3. Updating Firmware Regularly

Firmware updates often include bug fixes, performance improvements, and new features. For instance, Betaflight releases updates every few months, sometimes improving loop times from 4 kHz to 8 kHz for faster processing. Always test updates on a bench setup before flying to avoid unexpected issues.

Best Practices for Drone PCB Programming

As a developer, adopting best practices during drone PCB programming can save time and prevent costly errors. Here are some tips to follow:

- Modular Design: Design your PCB with modularity in mind, allowing easy swaps of components like IMUs or GPS modules to test different firmware compatibility.

- Documentation: Keep detailed notes on pin assignments, sensor specs, and firmware versions to streamline troubleshooting.

- Simulation: Use simulation tools to test firmware behavior with your PCB design before physical prototyping. This can reveal timing issues or hardware conflicts early.

- Community Resources: Leverage forums and wikis for each firmware to learn from other developers’ experiences and solutions.

Challenges in Drone Flight Controller Firmware Development

While working with drone flight controller firmware, developers often face challenges that can impact project timelines. Being aware of these issues helps in planning and mitigation:

- Compatibility Issues: Not all firmware versions support older hardware, leading to potential redesigns of the PCB.

- Learning Curve: Complex software like ArduPilot requires significant time investment to master, especially for custom scripting.

- Debugging: Identifying whether a flight issue stems from firmware or hardware can be tricky. Use logging features and systematic testing to isolate problems.

Patience and iterative testing are key to overcoming these hurdles and achieving a reliable drone system.

Conclusion: Choosing the Right Firmware for Your Drone PCB

Selecting the right drone flight controller firmware is a pivotal decision for developers working on flight control PCBs. Betaflight excels in high-performance FPV applications, ArduPilot is unmatched for autonomous missions, and iNav offers a balanced approach for navigation-focused drones. By understanding the strengths of each flight controller software and aligning them with your PCB design and project goals, you can build a drone that performs reliably and efficiently.

Remember to prioritize hardware compatibility, maintain signal integrity in your PCB layout, and leverage firmware features to optimize flight behavior. With careful planning and iterative testing, you can navigate the complexities of drone PCB programming and create cutting-edge drone solutions.

At ALLPCB, we’re committed to supporting developers with high-quality PCB manufacturing and assembly services tailored to drone projects. Whether you’re prototyping a new flight controller or scaling production, our expertise ensures your hardware is ready for the skies.

ALLPCB

ALLPCB