In the fast-paced world of electronics, safeguarding printed circuit boards (PCBs) from overcurrent events is critical to ensuring device reliability and safety. PCB fuses serve as the first line of defense, protecting sensitive components from damage due to short circuits, overloads, or voltage spikes. Selecting the right fuse for your PCB design can mean the difference between a robust, long-lasting product and costly failures. In this guide, we explore the essentials of PCB fuses, their types, selection criteria, and best practices to help engineers make informed decisions.

Whether you're designing consumer electronics, automotive systems, or industrial machinery, understanding how to choose the right fuse is key to optimizing performance and safety. Let's dive into the details of overcurrent protection and how to select the perfect PCB fuse for your application.

Recommended Reading: Creepage Distance: Your Comprehensive Guide for PCB Design Safety

What Are PCB Fuses and Why Are They Important?

A PCB fuse is a small, sacrificial device integrated directly onto a printed circuit board to protect circuits from excessive current. When current exceeds the fuse's rated value, its internal element—typically a metal wire or strip—melts, breaking the circuit and preventing damage to downstream components. This rapid interruption minimizes risks like overheating, component failure, or even fire hazards. For example, in a smartphone PCB, a fuse can protect delicate ICs from a short circuit caused by a faulty battery, preserving the device's functionality.

Without proper overcurrent protection, excessive current can wreak havoc. It can melt solder joints, burn PCB traces, or permanently damage integrated circuits. According to industry studies, overcurrent events account for approximately 30% of electronic device failures, highlighting the critical role of fuses in PCB design. By acting as a controlled weak link, fuses ensure that faults are isolated before they cascade through the system.

Types of PCB Fuses

PCB fuses come in various types, each designed for specific applications and performance requirements. Understanding these options is crucial for selecting the right fuse for your design. Below are the most common types of PCB fuses:

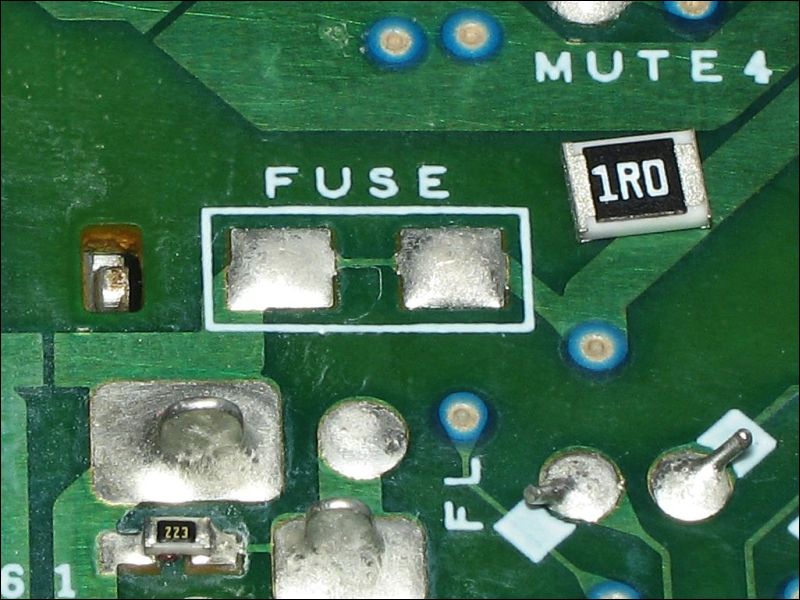

Surface-Mount (SMD) Fuses

Surface-mount fuses are compact devices soldered directly onto the PCB's surface, making them ideal for high-density, modern electronics like smartphones and laptops. Available in standard package sizes (e.g., 1206, 0805), SMD fuses offer current ratings from 0.5A to 10A and voltage ratings up to 250V. Their small footprint and compatibility with automated assembly processes make them a popular choice for space-constrained designs.

Through-Hole Fuses

Through-hole fuses, with wire leads inserted into PCB holes, are used in applications requiring mechanical strength, such as industrial control systems. These fuses are easier to replace manually and can handle higher current ratings, often up to 20A. However, their larger size makes them less suitable for compact designs.

Resettable (PTC) Fuses

Polymeric Positive Temperature Coefficient (PPTC) fuses, also known as resettable fuses, are unique because they don't require replacement after tripping. When an overcurrent event occurs, the polymer material heats up, increasing resistance and limiting current flow. Once the fault is cleared and the fuse cools, it resets automatically. These fuses are ideal for applications with frequent transient surges, such as USB ports or telecommunications equipment, with typical trip currents ranging from 0.1A to 5A.

Fast-Blow vs. Slow-Blow Fuses

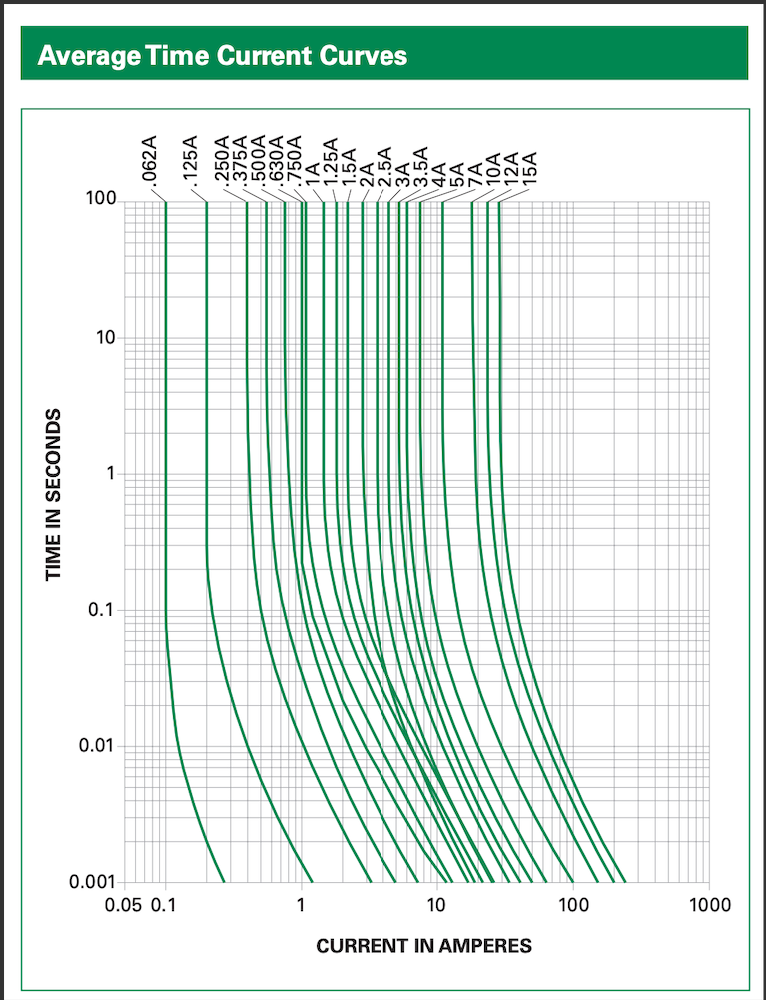

Fuses are also categorized by their response time. Fast-blow fuses react almost instantly to overcurrent, making them suitable for protecting sensitive components like microcontrollers, where even a brief surge can cause damage. Slow-blow fuses, on the other hand, tolerate temporary surges—such as inrush currents during capacitor charging—and are used in power supplies or motor circuits. For example, a slow-blow fuse rated at 2A might withstand a 4A surge for 100ms without blowing.

Key Factors in Choosing a PCB Fuse

Selecting the right PCB fuse requires careful consideration of several electrical and environmental factors. Here's a breakdown of the key parameters to evaluate:

Current Rating

The current rating indicates the maximum continuous current the fuse can handle without tripping. To choose the right rating, calculate the circuit's normal operating current and add a safety margin—typically 20-25%. For example, if a circuit draws 1.6A under normal conditions, a 2A fuse provides adequate protection while avoiding nuisance tripping. Undersizing the fuse can lead to frequent blowouts, while oversizing it risks insufficient protection.

Voltage Rating

The voltage rating specifies the maximum voltage the fuse can safely interrupt. It must be equal to or greater than the circuit's operating voltage. For instance, a 12V automotive PCB should use a fuse with at least a 12V rating, though 32V or 125V fuses are common for added safety. Using a fuse with a lower voltage rating can result in arcing or failure to break the circuit.

Breaking Capacity

Breaking capacity, or interrupting rating, is the maximum fault current the fuse can safely interrupt without causing damage. In high-power systems, short-circuit currents can reach thousands of amps. A typical SMD fuse might have a breaking capacity of 50A at 32V, while industrial fuses may handle up to 10,000A. Always ensure the fuse's breaking capacity exceeds the worst-case fault current in your circuit.

Response Time

The fuse's time-current curve dictates how quickly it responds to overcurrent. Fast-blow fuses are ideal for sensitive electronics, reacting in milliseconds, while slow-blow fuses allow brief surges, making them suitable for circuits with high inrush currents. Review the circuit's requirements and component tolerances to choose the appropriate response time.

Environmental Considerations

Operating conditions like temperature, humidity, and vibration can affect fuse performance. For example, fuses in automotive or marine applications may need to withstand temperatures from -40°C to 125°C or resist moisture. Sealed fuses or those with low-inductance materials are designed for such harsh environments. Always check the fuse's datasheet for environmental ratings.

Best Practices for PCB Fuse Integration

Proper fuse integration enhances circuit reliability and simplifies maintenance. Follow these best practices to optimize your PCB design:

- Place Fuses Near the Power Source: Position the fuse as close as possible to the power input (e.g., battery or power supply) to protect the entire circuit. This minimizes the risk of downstream damage during an overcurrent event.

- Consider Accessibility: For through-hole or replaceable fuses, ensure they are easily accessible for inspection and replacement. In compact designs, SMD fuses can be wave-soldered during assembly for efficiency.

- Test During Assembly: Perform continuity and electrical tests during PCB assembly to verify fuse functionality. This ensures the fuse operates within its specified parameters before deployment.

- Consult Experts: Work with experienced engineers or manufacturers to validate fuse selection, especially for complex or high-stakes applications. Their insights can prevent costly design oversights.

- Adhere to Standards: Ensure fuses comply with industry standards like UL (Underwriters Laboratories) or IEC (International Electrotechnical Commission) for safety and reliability.

Common Mistakes to Avoid

Even experienced engineers can make errors when selecting or integrating PCB fuses. Here are some pitfalls to watch out for:

- Overlooking Inrush Currents: Failing to account for inrush currents can lead to nuisance tripping. Use slow-blow fuses or consult component datasheets to estimate peak currents.

- Ignoring Breaking Capacity: A fuse with insufficient breaking capacity may fail to interrupt high fault currents, causing damage or safety hazards.

- Neglecting Derating: High ambient temperatures reduce a fuse's current-carrying capacity. Apply derating factors (e.g., 0.8x for 85°C environments) to ensure reliable operation.

- Using Non-Certified Fuses: Uncertified or low-quality fuses may have inconsistent performance, compromising safety. Always source fuses from reputable manufacturers.

How ALLPCB Supports Your PCB Fuse Integration

At ALLPCB, we understand the importance of reliable overcurrent protection in PCB design. Our advanced manufacturing capabilities and quick-turn prototyping services empower engineers to test and refine fuse integration with precision. With global logistics and a commitment to high-quality standards, we deliver PCBs that meet your exact specifications, whether you're designing for consumer electronics or industrial applications. Our expert team is also available to provide guidance on component selection, ensuring your fuses align perfectly with your circuit's requirements.

Conclusion

Choosing the right PCB fuse is a critical step in designing reliable, safe, and efficient electronic systems. By understanding the types of fuses, key selection criteria, and best practices for integration, engineers can protect their circuits from overcurrent events and extend device longevity. Whether you opt for an SMD fuse for a compact design or a resettable PTC fuse for transient protection, careful planning and testing are essential. At ALLPCB, we're here to support your journey with high-quality PCBs and expert guidance. Take the time to evaluate your circuit's needs, consult with professionals, and select a fuse that ensures robust overcurrent protection.

ALLPCB

ALLPCB