Are you a smart home startup looking to create innovative devices without breaking the bank? Designing printed circuit boards (PCBs) can be a costly process, but with the right strategies, you can achieve cost-effective PCB design and keep your project on budget. In this guide, we’ll share five practical tips to help you save money on PCB design, prototyping, and manufacturing. From using open-source tools to smart component sourcing, these tips will help you build high-quality PCBs for your smart home products while reducing PCB manufacturing costs.

Whether you’re working on smart thermostats, lighting controls, or security sensors, these actionable ideas will streamline your process and maximize your resources. Let’s dive into the details of affordable PCB prototyping and beyond!

Why Cost-Effective PCB Design Matters for Smart Home Startups

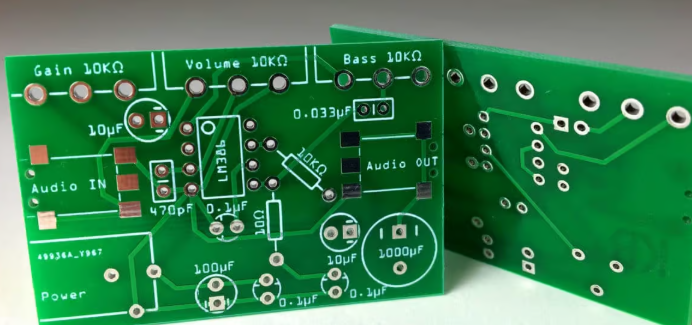

For smart home startups, every dollar counts. PCBs are the backbone of your devices, connecting sensors, microcontrollers, and wireless modules to bring your ideas to life. However, design mistakes or inefficient processes can lead to high costs during prototyping and production. By focusing on cost-effective PCB design, you can iterate faster, test more ideas, and bring your products to market without overspending.

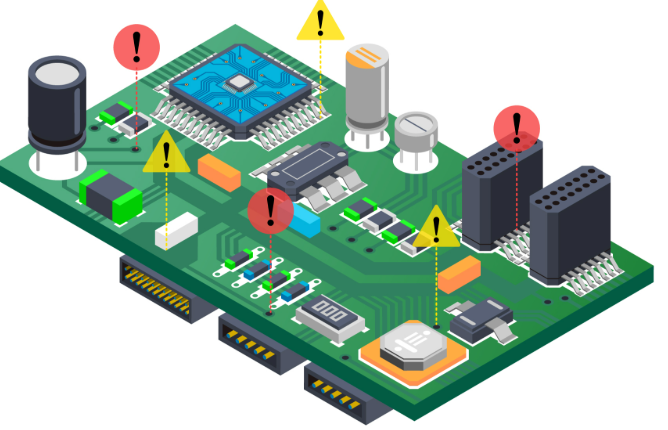

The smart home industry is growing rapidly, with devices often requiring complex circuits to handle Wi-Fi, Bluetooth, and IoT protocols. A single redesign due to a layout error or poor component choice can cost thousands of dollars and delay your launch. That’s why adopting strategies for reducing PCB manufacturing costs from the start is crucial. Let’s explore five proven tips to help you save money while maintaining quality.

Tip 1: Optimize Your PCB Layout for Simplicity

One of the easiest ways to achieve cost-effective PCB design is to simplify your layout. A complex design with unnecessary layers or tight spacing can increase manufacturing costs and lead to errors. Keep your design as minimal as possible while meeting the functional needs of your smart home device.

For example, aim for a two-layer board instead of a four-layer one unless your design absolutely requires additional layers for high-speed signals or dense routing. A two-layer PCB can cost 30-50% less to manufacture than a multi-layer board. Additionally, avoid overcomplicating trace widths and spacing. Stick to standard design rules, such as a minimum trace width of 6 mils (0.152 mm) and spacing of 6 mils, which most manufacturers can handle without charging extra for precision work.

Another way to simplify is to reduce the board size. Smaller boards use less material, which directly lowers costs. For instance, a PCB sized 50x50 mm will be significantly cheaper than one sized 100x100 mm, often saving you 20-40% on prototyping fees. Use design software to arrange components tightly (but safely) to minimize board area while ensuring proper heat dissipation and signal integrity.

By focusing on simplicity, you not only save on reducing PCB manufacturing costs but also speed up the prototyping phase, allowing for quicker iterations of your smart home product designs.

Tip 2: Leverage Open Source PCB Design Tools

Designing PCBs doesn’t have to come with a hefty price tag for software licenses. Using open source PCB design tools is a fantastic way for smart home startups to cut costs without sacrificing quality. These tools offer powerful features for schematic capture and layout design, often rivaling paid software, and they’re completely free to use.

Popular open-source options include software that allows you to create professional-grade designs with support for complex routing, design rule checks (DRC), and even 3D visualization. These tools often have active communities where you can find tutorials, libraries, and shared designs tailored for IoT and smart home applications. For instance, you can download pre-made schematics for common smart home components like ESP32 Wi-Fi modules or MQTT-enabled microcontrollers, saving hours of design time.

By using free tools, you can allocate your budget to other critical areas, such as affordable PCB prototyping or component purchases. Plus, many of these platforms export files in standard formats like Gerber, ensuring compatibility with most manufacturing services. Start exploring open-source options to keep your design costs at zero while maintaining flexibility and control over your projects.

Tip 3: Source Components Strategically

A major part of reducing PCB manufacturing costs lies in smart PCB component sourcing. The components you choose for your smart home devices can significantly impact your overall budget. High-end or hard-to-find parts not only increase costs but can also delay production due to long lead times.

Start by selecting components that are widely available and have multiple suppliers. For example, instead of using a niche microcontroller with limited stock, opt for a popular alternative like an ARM-based chip that’s used in many IoT devices. These parts often cost less due to high production volumes—sometimes as low as $1-2 per unit compared to $5-10 for specialty chips. Check distributor websites for stock levels and pricing to ensure availability.

Another tip is to use surface-mount devices (SMD) instead of through-hole components where possible. SMD parts are cheaper to assemble in bulk because they can be placed by automated machines, reducing labor costs during manufacturing. For instance, a 0603-sized resistor might cost just $0.01 per unit in quantities of 1,000, compared to $0.05 for a through-hole equivalent.

Finally, consider buying components in bulk to take advantage of volume discounts. Even for prototyping, ordering slightly more than you need can save money in the long run. By planning your PCB component sourcing carefully, you can keep costs down without compromising on the performance of your smart home products.

Tip 4: Prioritize Affordable PCB Prototyping Services

Prototyping is a critical step for smart home startups, as it allows you to test and refine your designs before mass production. However, it can also be expensive if not approached wisely. Choosing affordable PCB prototyping services is key to staying within budget while still getting high-quality boards for testing.

Look for manufacturers that offer low-cost options for small-batch orders. Many services provide competitive pricing for quantities as low as 5-10 boards, with costs starting at just $5-10 for a small two-layer design. Be sure to compare turnaround times as well—faster delivery often comes with a premium, so balance speed with cost based on your project timeline.

Another way to save is by panelizing your designs. If you’re ordering multiple small PCBs, ask the manufacturer to place them on a single panel. This reduces material waste and can cut costs by up to 25%. For example, producing five 50x50 mm boards individually might cost $25, but panelizing them into one 100x125 mm board could drop the price to $18-20.

Lastly, double-check your design files before submission to avoid costly revisions. Use design rule checks in your software to catch errors like incorrect trace spacing or missing vias. A single mistake can lead to a non-functional prototype, wasting both time and money. With careful planning, affordable PCB prototyping becomes an achievable goal for any startup.

Tip 5: Plan for Scalability to Reduce Long-Term Costs

While focusing on immediate costs is important, planning for scalability can save you significant money as your smart home startup grows. Designing with future production in mind ensures that your cost-effective PCB design remains viable when you move from prototyping to full-scale manufacturing.

For instance, design your PCB to use components that are not only affordable now but also likely to remain in production for years. Avoid parts that are nearing the end of their lifecycle, as replacements can be expensive or require a full redesign. Check manufacturer datasheets or distributor notifications for “end-of-life” warnings on chips or modules critical to your design, such as Wi-Fi transceivers commonly used in smart home devices.

Additionally, consider design for manufacturability (DFM). This means creating a PCB layout that’s easy and cost-efficient to assemble in large quantities. For example, place components on one side of the board if possible, as single-sided assembly reduces labor costs by 10-20% compared to double-sided assembly. Also, ensure that test points are accessible for automated testing during production, which can save hours of manual debugging.

By thinking ahead, you can avoid expensive redesigns and ensure that reducing PCB manufacturing costs remains a priority even as your production volume increases. Scalability is the key to long-term savings and success in the competitive smart home market.

Additional Tips for Smart Home Startups

Beyond the five main strategies, here are a few extra pointers to enhance your cost-effective PCB design journey:

- Collaborate with Communities: Join online forums and groups focused on IoT and smart home development. These communities often share free resources, design tips, and even Gerber files for common smart home circuits, saving you design time.

- Test Incrementally: Don’t rush to prototype a fully featured board. Start with smaller modules (e.g., just the power supply or sensor circuit) to test critical functions before integrating everything. This minimizes waste if a section fails.

- Reuse Designs: If your smart home product line includes multiple devices, reuse PCB sections like power management or communication circuits across products. This reduces design effort and bulk component costs.

These small steps can add up to significant savings, especially when paired with strategies like open source PCB design tools and careful PCB component sourcing.

Conclusion: Building Smart Home Success on a Budget

Creating innovative smart home devices doesn’t have to come with a high price tag. By following these five cost-effective PCB design tips, you can save money at every stage—from initial design to full-scale production. Simplifying layouts, using open source PCB design tools, sourcing components wisely, prioritizing affordable PCB prototyping, and planning for scalability are all proven ways to keep your budget in check.

As a smart home startup, your focus should be on delivering value to customers through reliable, well-designed products. By adopting strategies for reducing PCB manufacturing costs and optimizing PCB component sourcing, you’ll have more resources to invest in innovation and growth. Start implementing these tips today to build high-quality PCBs without overspending, and watch your smart home ideas come to life.

At ALLPCB, we’re committed to supporting startups with solutions tailored to your needs. Explore our services to see how we can help you achieve your design and manufacturing goals efficiently and affordably.

ALLPCB

ALLPCB