In the fast-paced world of PCB manufacturing, sourcing electromechanical components in a cost-effective way is crucial for maintaining profitability and meeting project deadlines. Whether you're a small-scale manufacturer or managing large production runs, finding the right balance between quality, price, and reliability can be challenging. So, how can you achieve cost-effective sourcing for electromechanical components? The answer lies in strategic planning, leveraging global networks, negotiating prices, and managing component lifecycles to avoid unexpected costs.

In this comprehensive guide, we'll dive deep into actionable strategies for sourcing electromechanical components for PCB manufacturing. We'll cover key areas such as price negotiation, global sourcing options, choosing between authorized and independent distributors, lifecycle cost management, obsolescence planning, and optimizing your supply chain. Let's explore how you can save costs without compromising on quality or performance.

Understanding the Importance of Cost-Effective Sourcing for Electromechanical Components

Electromechanical components, such as connectors, switches, relays, and motors, play a vital role in PCB assembly. These parts bridge the gap between electrical and mechanical functions, ensuring that your final product operates as intended. However, their costs can quickly add up, especially if you're dealing with high-volume production or complex designs that require specialized components.

Cost-effective sourcing isn't just about finding the cheapest parts. It’s about balancing price with reliability, availability, and long-term value. Poor sourcing decisions can lead to delays, defective products, or higher expenses due to rework and replacements. By implementing smart strategies, you can reduce costs while maintaining the high standards needed for your PCB projects.

Strategy 1: Mastering Electromechanical Component Price Negotiation

One of the most direct ways to reduce costs is through effective price negotiation for electromechanical components. Suppliers often have room for flexibility, especially if you're ordering in bulk or establishing a long-term relationship. Here are some tips to negotiate better deals:

- Research Market Prices: Before entering negotiations, gather data on standard pricing for the components you need. Use this as a benchmark to ensure you're getting a fair deal.

- Bulk Ordering Discounts: Many suppliers offer discounts for large orders. If your project timeline allows, consider consolidating orders to increase your purchasing volume and lower the per-unit custom PCB cost.

- Build Relationships: Establish trust with suppliers by maintaining consistent communication and fulfilling payment terms. A strong relationship can lead to better pricing over time.

- Request Quotes from Multiple Suppliers: Don’t settle for the first offer. Compare quotes from different vendors to create competition and drive prices down.

By focusing on electromechanical component price negotiation, you can save significantly on each order, allowing for better budget allocation across your PCB manufacturing process.

Strategy 2: Exploring Global Sourcing for Electromechanical Components

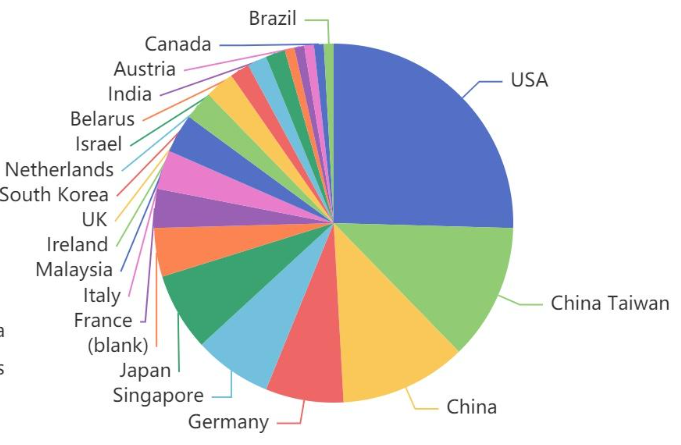

Global sourcing for electromechanical components opens up a world of opportunities to reduce costs. Different regions offer varying price points, quality levels, and lead times. For instance, sourcing from regions in Asia often provides lower costs due to economies of scale and established manufacturing hubs, while European suppliers might offer higher quality or faster shipping for urgent needs.

Here are key considerations for global sourcing electromechanical components:

- Understand Regional Strengths: Research which regions specialize in the components you need. For example, some countries excel in producing high-precision connectors, while others focus on cost-effective relays.

- Account for Shipping Costs and Tariffs: Factor in additional expenses like import duties and shipping fees. Sometimes, a lower component price can be offset by high logistics costs.

- Evaluate Lead Times: Global sourcing can involve longer delivery times. Plan your production schedule to avoid delays, especially for time-sensitive projects.

- Compliance with Standards: Ensure that components sourced globally meet industry standards like RoHS or IPC for safety and compatibility with your PCB designs.

By diversifying your supplier base across borders, you can tap into competitive pricing and build a more resilient supply chain.

Strategy 3: Authorized Distributors vs Independent Suppliers – Which is Better?

When sourcing electromechanical components, one critical decision is whether to work with authorized distributors or independent suppliers. Both options have pros and cons, and understanding them can help you make cost-effective choices. Let’s break down the debate of authorized distributors vs independent suppliers:

- Authorized Distributors:

- Pros: They provide guaranteed authentic components, technical support, and often have direct access to manufacturers for updates or replacements. This reduces the risk of counterfeit parts.

- Cons: Prices are typically higher due to their direct relationship with manufacturers and the added value of their services.

- Independent Suppliers:

- Pros: Often offer lower prices and more flexibility in negotiations. They may also stock hard-to-find or obsolete components.

- Cons: There’s a higher risk of counterfeit or substandard parts. You’ll need to perform thorough quality checks.

For cost-sensitive projects, independent suppliers might be tempting, but always prioritize quality assurance. A mix of both—using authorized distributors for critical components and independents for standard parts—can optimize costs while maintaining reliability.

Strategy 4: Managing Electromechanical Component Lifecycle Cost

The initial purchase price of electromechanical components is just one part of the equation. The total electromechanical component lifecycle cost includes expenses related to maintenance, replacements, and downtime due to failures. To minimize these costs, consider the following:

- Choose Durable Components: Opt for parts with proven reliability and longer operational lifespans. For example, a relay rated for 1 million cycles might cost more upfront but saves money by reducing replacement frequency.

- Predict Failure Rates: Use manufacturer data to estimate how often components might fail under your operating conditions. This helps in budgeting for replacements.

- Plan for Maintenance: Some electromechanical components, like switches, may require periodic cleaning or lubrication. Factor these costs into your overall budget.

By focusing on lifecycle costs rather than just purchase price, you can avoid unexpected expenses that impact your bottom line during PCB manufacturing.

Strategy 5: Obsolescence Management for Electromechanical Components

Obsolescence is a significant challenge in PCB manufacturing. When electromechanical components become outdated or discontinued, it can lead to redesigns, delays, and higher costs. Effective obsolescence management for electromechanical components can save you from these headaches. Here’s how to approach it:

- Monitor Manufacturer Announcements: Stay updated on end-of-life (EOL) notices from component manufacturers. This gives you time to source alternatives or stock up on critical parts.

- Use Multi-Source Components: Design your PCBs with components that have multiple compatible alternatives. This reduces dependency on a single part that might become obsolete.

- Stockpile Strategically: For critical components with a high risk of obsolescence, maintain a small inventory to bridge the gap while transitioning to replacements.

- Partner with Experts: Work with suppliers or distributors who can help identify drop-in replacements or redesign solutions if a component is discontinued.

Proactive obsolescence management ensures that your production line keeps running smoothly, even when components are no longer available.

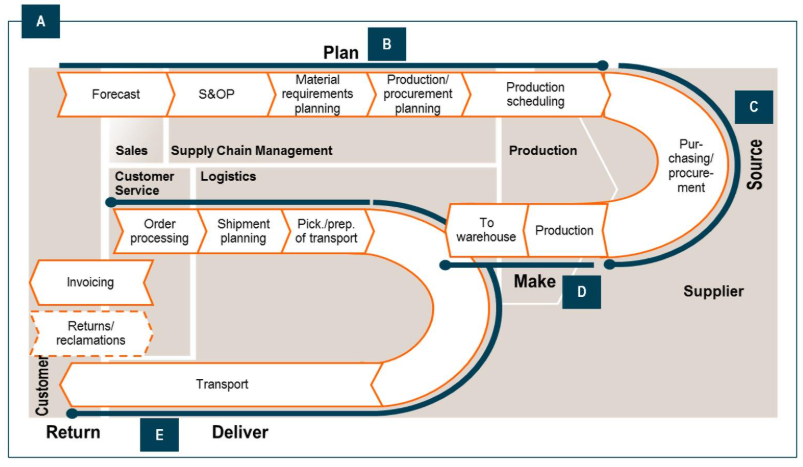

Strategy 6: Optimizing the Supply Chain for Electromechanical Components

A streamlined supply chain for electromechanical components is the backbone of cost-effective sourcing. Disruptions or inefficiencies in the supply chain can lead to delays and increased costs. Here are ways to optimize it:

- Diversify Suppliers: Avoid relying on a single supplier. Having multiple sources reduces the risk of shortages if one vendor faces issues.

- Use Technology for Forecasting: Implement inventory management software to predict demand and avoid overstocking or understocking components.

- Localize Where Possible: For urgent needs or small runs, consider local suppliers to cut down on shipping times and costs, even if the unit price is slightly higher.

- Regularly Review Performance: Evaluate your suppliers’ delivery times, quality, and pricing periodically. Switch to better options if performance drops.

A well-managed supply chain not only reduces costs but also improves the overall efficiency of your PCB manufacturing process.

Practical Tips for Implementing Cost-Effective Sourcing Strategies

Now that we’ve covered the core strategies, here are some additional tips to help you apply these concepts in real-world PCB manufacturing:

- Start Small: Test new suppliers or sourcing methods with smaller orders before committing to large contracts. This minimizes risk if issues arise.

- Leverage Industry Networks: Join forums or trade groups to learn from other manufacturers about reliable suppliers and cost-saving techniques.

- Document Everything: Keep detailed records of supplier agreements, pricing history, and component performance to inform future sourcing decisions.

- Stay Updated on Market Trends: Fluctuations in raw material prices or geopolitical events can impact component costs. Monitor these factors to time your purchases strategically.

Conclusion: Building a Sustainable Sourcing Strategy

Cost-effective sourcing for electromechanical components in PCB manufacturing requires a multi-faceted approach. By mastering price negotiation, exploring global sourcing opportunities, choosing the right distributors, managing lifecycle costs, planning for obsolescence, and optimizing your supply chain, you can significantly reduce expenses while maintaining quality. These strategies not only save money but also build resilience into your production process, ensuring that you’re prepared for challenges like shortages or discontinued parts.

At ALLPCB, we understand the importance of efficient and affordable sourcing. Our expertise in PCB manufacturing and component procurement can help you navigate these complexities with ease. Start implementing these strategies today to see immediate improvements in your project budgets and timelines. With the right approach, cost-effective sourcing becomes a competitive advantage in the ever-evolving world of electronics manufacturing.

ALLPCB

ALLPCB