If you're searching for a reliable, budget-friendly way to create high-performance printed circuit boards, Arlon PCB prototyping offers an excellent solution. Known for its superior materials and suitability for demanding applications, Arlon PCB materials help engineers achieve quick turnarounds and small batch production without breaking the bank. In this blog, we’ll explore how using Arlon PCB for prototyping can save costs while delivering top-tier performance, especially for Arlon PCB quick turn and Arlon PCB small batch needs. We'll also break down the Arlon PCB prototype cost factors to help you plan your next project.

At ALLPCB, we understand the importance of balancing quality and affordability. That’s why we’ve put together this detailed guide to help engineers and designers make informed decisions when prototyping with Arlon materials. Let’s dive into the benefits, processes, and tips for getting the most out of your PCB projects.

What Makes Arlon PCB Stand Out for Prototyping?

Arlon PCB materials are widely recognized in the electronics industry for their high-performance characteristics. These materials, often used in advanced applications like aerospace, automotive, and telecommunications, are designed to handle extreme conditions while maintaining signal integrity. But what sets Arlon apart when it comes to prototyping?

First, Arlon laminates are engineered with low dielectric constants and low loss tangents, typically ranging from 2.2 to 3.5 for dielectric constant and 0.002 to 0.003 for loss tangent at high frequencies (around 10 GHz). This ensures minimal signal loss, making them ideal for high-speed digital and RF designs. For engineers working on prototypes that require precise impedance control, such as 50 ohms for RF circuits, Arlon materials provide consistent performance.

Second, Arlon PCB materials are durable and thermally stable, with glass transition temperatures (Tg) often exceeding 170°C. This stability is crucial during prototyping, where designs may undergo multiple iterations and testing under varying conditions. Whether you’re designing a small batch for validation or need a quick-turn prototype to meet tight deadlines, Arlon’s reliability reduces the risk of failures during testing.

Why Choose Arlon PCB for Cost-Effective Prototyping?

One of the biggest challenges in PCB prototyping is managing costs without sacrificing quality. This is where Arlon PCB prototype cost considerations come into play. While Arlon materials are often associated with premium applications, they can be surprisingly cost-effective for prototyping when used strategically. Here’s why:

- Reduced Iterations: Thanks to their predictable electrical and thermal performance, Arlon materials often lead to fewer design revisions. For instance, achieving a target impedance of 50 ohms on the first try can save significant time and money compared to multiple redesigns with lower-quality materials.

- Small Batch Compatibility: For Arlon PCB small batch production, the material’s consistency ensures that even limited runs maintain high quality. This is ideal for startups or engineers testing a concept before full-scale production.

- Long-Term Savings: While the upfront cost of Arlon materials might be higher than standard FR-4 (by about 20-30% depending on specifications), the reduced risk of failures and enhanced performance can lower overall project costs by avoiding costly rework.

By partnering with a trusted provider like ALLPCB, you can further optimize costs through efficient manufacturing processes tailored for prototyping. We focus on delivering value by streamlining production for small batches and quick turnarounds, ensuring you get the most out of your investment in Arlon materials.

Arlon PCB Quick Turn: Speed Without Compromise

Time is often a critical factor in prototyping. Whether you’re racing to meet a product launch deadline or need to validate a design before a funding round, Arlon PCB quick turn services can make all the difference. Arlon materials are well-suited for rapid prototyping due to their compatibility with standard PCB fabrication processes, allowing for faster production without sacrificing performance.

For example, a typical quick-turn prototype using Arlon laminates can be completed in as little as 24 to 48 hours for bare boards, depending on complexity. This speed is achievable because Arlon materials have consistent manufacturing parameters, such as stable dielectric thickness (often around 0.005 to 0.060 inches), which minimizes setup time during fabrication.

At ALLPCB, we prioritize speed for quick-turn projects. Our advanced manufacturing capabilities ensure that even high-performance designs using Arlon materials are delivered on tight schedules, helping you stay ahead in competitive markets.

Small Batch Production with Arlon PCB: Perfect for Testing and Validation

For many engineers, producing a small batch of PCBs is a critical step in the design validation process. Arlon PCB small batch production offers a practical solution for creating limited runs of high-quality boards without the expense of full-scale manufacturing.

Arlon materials are particularly advantageous for small batches because they provide uniform performance across all units. For instance, in a batch of 10 prototype boards for an RF application, Arlon’s low loss tangent ensures that signal integrity remains consistent, with variations in insertion loss often below 0.1 dB at 5 GHz. This uniformity reduces the likelihood of discrepancies during testing, giving you confidence in your results.

Additionally, small batch production with Arlon materials allows for targeted testing of specific design features. Whether you’re evaluating thermal performance under high-power conditions or testing signal speeds for a 5G application, Arlon’s high-performance characteristics provide reliable data to inform your next steps.

Understanding Arlon PCB Prototype Cost Factors

When planning a prototyping project, understanding the Arlon PCB prototype cost is essential for budgeting. While costs can vary based on design complexity and production requirements, here are the key factors that influence pricing:

- Material Selection: Arlon offers a range of laminates with different properties, such as varying dielectric constants and thermal ratings. Higher-performance options, like those with a dielectric constant of 2.2 for ultra-high-frequency applications, may cost more than standard options.

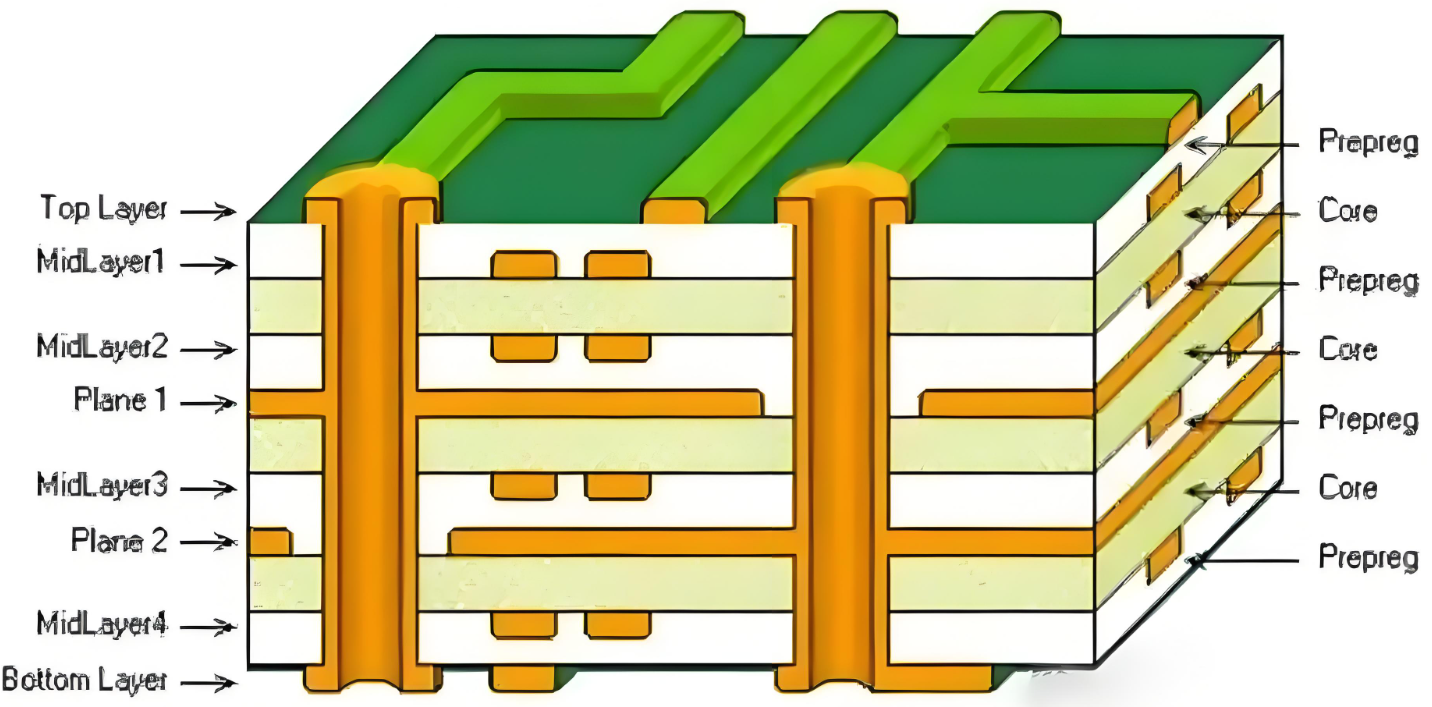

- Board Complexity: Designs with multiple layers (e.g., 6 or 8 layers) or tight tolerances (e.g., trace widths below 4 mils) increase fabrication costs due to the precision required.

- Turnaround Time: Opting for Arlon PCB quick turn services often comes with a premium, as expedited production requires dedicated resources. However, this cost can be offset by faster time-to-market.

- Batch Size: Smaller batches, such as 5 to 20 units, typically have a higher per-unit cost compared to larger runs due to setup fees. However, for prototyping, this is often a worthwhile trade-off to minimize upfront investment.

To give a rough estimate, a simple 2-layer Arlon PCB prototype with standard specifications (e.g., 1.6mm thickness, 1 oz copper) might start at around $50 to $100 for a small batch of 5 boards, with costs decreasing per unit for larger quantities. At ALLPCB, we provide transparent pricing and work with you to optimize costs based on your specific needs.

Tips for Maximizing Value in Arlon PCB Prototyping

To get the most out of your Arlon PCB prototyping experience, consider these practical tips:

- Optimize Your Design Early: Use simulation tools to verify impedance values and signal integrity before fabrication. For example, ensuring your design achieves a 50-ohm impedance for RF lines can prevent costly revisions.

- Start with Small Batches: Begin with a limited run to test critical features. Once validated, scale up production to benefit from economies of scale.

- Collaborate with Experts: Work closely with your PCB provider to select the right Arlon material for your application. For high-frequency designs, a laminate with a dielectric constant of 3.0 might suffice, saving costs compared to more specialized options.

- Prioritize Quick-Turn Services: If time is critical, invest in expedited production. The slight increase in cost can be outweighed by the advantage of faster feedback loops.

At ALLPCB, we’re committed to supporting engineers through every step of the prototyping process. Our team offers guidance on material selection, design optimization, and production planning to ensure your project succeeds.

Applications of Arlon PCB Prototyping

Arlon PCB materials are versatile and can be used across a wide range of industries and applications. Here are some common use cases for prototyping with Arlon:

- Telecommunications: For 5G and high-frequency applications, Arlon’s low-loss materials ensure signal speeds remain consistent, often exceeding 10 Gbps in controlled environments.

- Automotive: In advanced driver-assistance systems (ADAS), Arlon PCBs withstand harsh thermal cycles, maintaining performance at temperatures up to 150°C.

- Aerospace: Arlon materials meet stringent reliability standards for radar and communication systems, with dielectric stability under varying altitudes and pressures.

- Medical Devices: For wearable and diagnostic equipment, Arlon’s precision supports compact, high-density designs with minimal signal interference.

These applications highlight the adaptability of Arlon materials, making them a go-to choice for engineers tackling complex challenges during prototyping.

Conclusion: Why Arlon PCB Prototyping is a Smart Choice

Prototyping with Arlon PCB materials offers a winning combination of high performance and cost-effectiveness, especially for engineers focused on Arlon PCB quick turn and Arlon PCB small batch production. With superior electrical properties, thermal stability, and compatibility with rapid manufacturing processes, Arlon ensures your prototypes meet the highest standards without unnecessary expenses.

By understanding the factors that influence Arlon PCB prototype cost and leveraging the expertise of a trusted provider like ALLPCB, you can streamline your development process and bring innovative designs to life. Whether you’re working on a cutting-edge telecommunications project or a rugged automotive system, Arlon PCB prototyping provides the reliability and efficiency you need to succeed.

Ready to start your next project? At ALLPCB, we’re here to help you navigate the world of high-performance PCB prototyping with Arlon materials. Let’s turn your ideas into reality with precision and speed.

ALLPCB

ALLPCB